The expansion tank is almost irreplaceable in the water supply of a country house. It allows you to stock up on an additional volume of water in case of shutdown, or to avoid the loss of this liquid when it is heated by the boiler system.

Functions of expansion tanks for water supply systems

The expansion tank with internal pressure is universal, therefore it can be used for several purposes. The first method of application is in a water heating system with boilers as an additional tank for removal during thermal expansion. Another application is a hydraulic accumulator.

Despite the different functions performed, the tank in both cases has an identical design. It consists of a closed-type steel body with an inner space that is divided in half by an elastic membrane. The upper compartment contains compressed air (nitrogen is sometimes used), and liquid is pumped into the lower compartment.

Expansion tank as battery

The tank is connected to the system in order to accumulate additional water in case the water supply is cut off. The principle of operation is as follows: the tank is connected by a branch pipe to the water supply pipes at any point, and when the tap is opened, the water begins to fill the container. A check valve is installed on the connection, which prevents water from flowing back.

As soon as the liquid enters, the membrane begins to move upward until the pressure of the compressed air above it equals the pressure of the water in the system. It should be borne in mind that the useful volume of the tank is about half of the total. At the moments of disconnection of the water supply, the liquid can be pumped out of the container through another valve.

Expansion tank for boiler

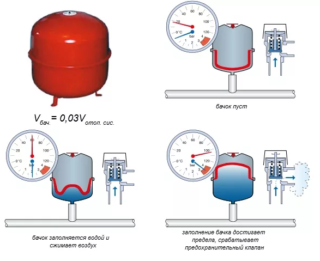

Water tends to expand when heated. When its temperature rises, the volume begins to increase. Since the tank of the heating system is initially filled completely, excess liquid flows out.

To avoid water loss, an expansion tank installed above the boiler is additionally used. It takes in the surplus. The usable space inside the tank should be approximately 10% of the boiler volume.

Normal pressure

The manual for the unit says what pressure should be in the expansion tank of the water supply system by default in this configuration. It is usually between 1 and 3 bar.

The required indicator also depends on where the tank is located relative to the water supply system to which it is connected. According to standard rules, the container should be 0.2 atmospheres more. If they are on the same level, this difference will be enough.

If the height between the expansion tank and the heating system is 12 m, an additional 1 atm must be added for every 10 meters. It turns out that for the given conditions, the pressure inside the tank will be normal, which is 0.2 + 1.2 = 1.4 atmospheres higher than the water supply.

How to measure the pressure in the expansion tank

If the tank does not have a built-in pressure gauge, you must use a portable analogue. The removable pressure measuring device has the same connection as the expansion tank outlet valve at the top. You need to put it on and fasten it tightly. Then open the valve so that the pressure gauge with the tank becomes one system. The arrows on the device will show the current internal pressure.

Adjusting indicators

At times, the pressure in the expansion tank drops, so it must be pumped up periodically to keep the efficiency of the device at the same level. Each diaphragm vessel has a spool valve. It can be connected to a bicycle or car pump, or a compressed gas cylinder.

The diaphragm water supply tank can be pumped manually or using an automatic pump. If you are using a compressed air cylinder, no additional effort is required. It is necessary to connect it to the container with a special hose. Then open a valve on the cylinder that releases gas, which, under pressure, will itself fill the closed expansion tank.

It is necessary to carefully monitor the readings of the pressure gauge in order to tighten the valve in time, as soon as the correct pressure is established inside.