Coarse water filters for an apartment are designed to trap impurities larger than 100 microns. There are filtering devices on the market that can contain contamination larger than 50 microns, and their specialists classify them as coarse cleaning, although the standard degree of cleaning is exactly 100 microns.

Where are coarse filters used?

The scope of this type of devices is extensive. Manufacturers mainly offer filter elements that are installed in water supply systems for various purposes. These are not only centralized networks, but also autonomous ones - with the organization of water intake from wells, wells or open reservoirs.

In centralized water supply systems, the quality of water is close to that of drinking, in autonomous systems, filtration is necessary even if the water is taken from a deep well. Small particles of sand, pebbles, detachment of rocks, etc. - this is a small list of what can penetrate the water supply network, ruining not only household appliances, but also a pipeline with valves.

In city apartments, water pre-purification filters are also installed. Inside apartment buildings, plastic pipes are installed almost everywhere. This is a guarantee of the purity of the liquid flowing through them. However, in some buildings, steel pipes are installed or are being laid, which corrode during intensive operation, therefore, exfoliated metal oxides in the form of solid particles will penetrate into the water.

Types of coarse filters

The main task is to block the path of large solid inclusions in the water into the pump. The mesh practically does not increase the cost of the plumbing system, but it plays an important role in it. The stainless steel will last a long time, large cells practically do not clog, which makes it possible to often clean it.

Filtering devices can be purchased on the market, which are represented by models similar to fittings or shut-off valves of the pipeline system. Such filters are cut into the pipe using split couplings, which are popularly called Americans. By its design, it is a tubular element, in the middle of which a hollow cylinder is installed (vertically or at an angle). It contains a stainless steel mesh, twisted into a tube. The filter element blocks the flow of moving water. To be able to periodically clean the mesh, a removable cover is installed on top, which is connected to the device by means of a thread.

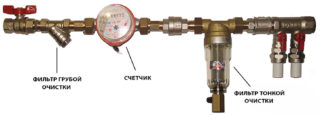

A coarse water filter is easy to cut into a pipe even inside an apartment or a private house. Usually it is installed in front of the meter for accounting and control of fluid consumption.

Mud traps

This type of coarse filter differs from all others in the way of retaining contamination. This is a main filter that is connected to the pipe using threads or flanges. In its design, there is a large cavity located perpendicular to the movement of the fluid flow.

The technology of water purification consists in the fact that it, getting into the cavity, quickly loses its speed. Heavy particles immediately begin to sink to the bottom under the influence of their own weight. The mud collectors got their name because a large amount of dirt accumulates inside them, which must be periodically removed. The dirtier the water passes through these devices, the more intensively they fill up.

Mud traps (sedimentation tanks) are usually installed first in the water supply network. Therefore, they take on the greatest loads. In apartment buildings, they are installed in basements, cutting into a common water pipeline.

All mud collectors in their design have plugs through which the devices are cleaned. The plugs are attached to the body by means of a thread or in the form of a blind flange.

Filtering devices of this type can be installed in hot water supply and heating systems.

Mesh filters

This variety belongs to the category of flow-through main water filters. They are often called flushing. They cut into pipelines using a thread on an American.

Purely structurally, it is a steel or plastic (transparent) flask, inside which a stainless steel mesh (food grade) is inserted, twisted into a cylinder. There is a drain cock at the bottom of the body. Its purpose is to clean the filter element by flushing. The tap opens, the water is drained, drawing in the dirt that sticks to the mesh. Such cleaning cannot be called one hundred percent, therefore it is recommended to periodically open the filter, pull out the mesh and rinse it under the pressure of water or with a brush.

Some models have a backwash function. The water pressure is directed in the opposite direction of its course during normal operation of the device.

Some manufacturers complete mesh models with pressure gauges. They show the pressure inside the device. There are modifications with two pressure gauges. One is installed at the entrance, the other at the exit. The difference in readings makes it possible to determine whether the filter is clogged or not. The larger this parameter, the more dirt on the mesh.

Another type is completed with pressure reducers. With the help of the latter, you can adjust the pressure in the water supply. This is important if household appliances are used in a house or apartment that react negatively to high water pressure.

Cartridge filters

Cartridge devices are leaders in the coarse filter category. They have a simple design, low price, good technical and operational characteristics. They belong to the group of main filters, they cut into the pipeline with the help of American women.

The design consists of a flask (usually plastic, but there are also metal ones), which is connected to the flow part by a thread. The tightness of the connection is maintained by a rubber cuff. You can unscrew or screw on the coarse water filter by hand. But more often manufacturers include a special key in the package.

A cartridge is placed inside the flask. This is a cylindrical filter element. The principle of operation of the cartridge model is that water enters the flask, passes through the filter material and enters its cavity. From there it goes further.

Cartridge filters are classified according to the type of filter material. The choice in this regard is small. All elements are based on the same polymer - polypropylene. It was chosen for these purposes, since it is a chemically inert material.

Manufacturers offer three materials:

- randomly wound polypropylene filaments or fibers;

- corrugation;

- foamed sponge.

The filter elements cannot be cleaned or washed. Manufacturers indicate the periods during which the materials can be used, after which they must be replaced with new ones. This is the only drawback.

Criterias of choice

On the market, coarse filters are represented by a wide range of models.They differ in shape, size and materials from which they are made, as well as in the degree of purification. The performance of the device depends on the dimensions - the amount of water that the filter element must pass, taking into account the unit of time (l / min or l / hour).

For mesh filters, the degree of cleaning depends on the size of the mesh on the mesh. The smaller they are, the cleaner the liquid at the exit. For cartridges - the distance between the fibers, parts of the corrugation - the denser the polypropylene material, the higher the degree of purification.

In mud collectors, the larger the sediment chamber, the longer the service life with maximum time periods between cleanings.

Installation nuances

If the connecting element is reverse flanges, a rubber gasket must be installed between the filter and the pipe. If the device is installed in a hot water supply or heating system, instead of rubber, a security guard must be installed.

Cost of coarse filters

The price of the device depends on several factors. Basically, this is the material from which it is made, the dimensions of the structure and the type of filter element:

- an oblique sump made of brass with a 1 ”(one inch) thread costs 650 rubles;

- the same with a ½ ”thread - it costs 200 rubles;

- the same made of propylene with a ¾ ”thread - 100 rubles;

- straight brass sump with ½ ”thread - 300 rubles.

In cold water systems, it is better to use plastic devices. They are reliable and inexpensive. It is better to install metal products in hot water supply and heating networks. They can easily withstand high temperatures.