The disparate parts of the plumbing are assembled into a single system using fittings. The selection of plumbing fittings must be taken responsibly. The durability and stability of the functioning of the entire water supply network depends on them.

Purpose of plumbing fittings

According to their functional qualities, the shaped elements of the water supply system are divided into:

- reduction - used when it is necessary to connect pipe sections of different sections;

- straight - used when it is necessary to connect pipes of the same diameter.

One water main can be assembled from several pipe sections that are connected with different types of fittings.

The fittings for the water supply system must be economical, safe, and reliably connect the parts of the pipeline. If installed correctly, no leaks or condensation will form.

Main types

It is possible to subdivide shaped plumbing elements into two large groups:

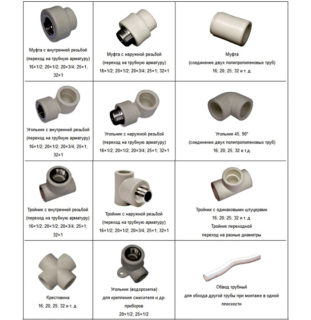

| Feature category | Connecting the pipeline into a single line | Used to change direction or connect additional elements |

| Common types of fittings | Adapters are used to connect elements of different sections. | Tees and crosses are mounted to combine several branches. |

| Fittings connect plastic and metal elements. | Bends at different angles are needed to change the direction of the line, and bypasses are needed to smoothly bypass vertical risers. | |

| Couplings are used to connect pipes of the same cross-section on a straight section of the water supply. | On the one hand, the water sockets are connected to the pipe, on the other they have an internal thread, to which the mixer eccentric or the water supply hose is connected. | |

| Benefits | They allow you to increase the length of straight main sections, connect various hoses to it, build in control or distribution systems. | They help when connecting several additional elements or lines to the main branch, for turning the highway. |

The cross-section of the pipeline branches using the fitting parts of both groups can be changed or remain unchanged.

The design largely depends on the connection method. There are two popular types of fittings: press fittings and compression fittings. The first is a housing with a crimp sleeve and a metal sleeve placed inside. The second ones have a similar structure, but instead of a sleeve there is a fitting, and a split ring is used as a clamp, corresponding to the outer section of the pipe. Both the first and the second are equipped with a fixing nut at the point where the pipe section is connected. But there are other options - with internal or external threads (metal only), installed using soldering or glue (plastic only).

Specifications and selection criteria

The main design characteristics to consider when choosing a part:

- inner and outer section;

- threaded diameter;

- operating pressure;

- temperature regime (fittings may differ for hot and cold water branches).

The sizes of the parts are also very different. For example, for polypropylene pipelines, fittings with a cross section of 16–63 mm are produced for systems with pressures up to 16 bar, and 75–110 mm for networks where the pressure reaches 75–100 bar.

The most commonly used fitting elements for plastic water pipes with a cross section of 20, 25, 30 and 40 mm. You can find fittings up to 110 mm, but they are usually used when laying pipelines for industrial use. In a private house or city apartment, the best option would be to lay a water supply system from pipes and fitting elements with a cross section of 20 mm.

Manufacturing material

Shaped elements for plumbing are made from various metals and polymers. Metal fittings can be:

- brass;

- copper;

- steel;

- cast iron.

The first two types are less susceptible to corrosion than the others.

Plastic options are made from polyethylene, low pressure polypropylene (HDPE) or polyvinyl chloride (PVC). The latter are installed on non-pressure water supply systems. Polyethylene products are installed both on systems without pressure and on pipelines with pressure, and propylene products are most often used for pressure systems.

The advantages of polymer parts are corrosion resistance, budget cost and a wide range. They are lightweight, durable and easy to install. The cost of such products starts from 40 rubles. The average price is 100–300 rubles.

Metal fittings cost 2 times more than, for example, PVC fittings for plastic water pipes. The advantage of metal elements over polymeric ones is in increased strength. In domestic water supply systems, this factor is not so significant, therefore, plastic pipes are increasingly being installed. Fittings must be made of suitable materials. It is not advisable to combine different types of pipes and fittings.

Installation features

Installation rules depend on the design of the element itself. For example, press fittings are often used to connect plastic pipe sections. This type of connection elements is considered the most reliable. Installation of press fittings is carried out using an electro-pneumatic press-clamp or special press tongs, which reduce the volume of the coupling area at the pipe connection point. When self-assembling the line, the tool may not be at hand, so you can use a simpler version of press fittings with crimping with a nut.

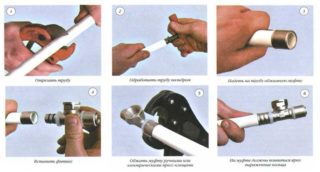

Installation is performed in the following sequence:

- The cuttings of the pipe are cleaned with a knife and dirty spots are removed.

- A nut is put on for fixing and a cut ring.

- Plumbing grease or petroleum jelly is applied to the inside of the ring. This allows the pipe to be connected without distortion.

- The cut ring is moved to the edge and twisted with a nut.

Installation of compression fitting elements is carried out using a wrench. On such fittings for water supply, the inner ferrule is tightened, due to which the fitting is fixed to the pipeline. The disadvantage of this reinforcement is that constant pulling is required.

Compression fittings, unlike press fittings, are much easier to install. But due to the direct influence of the human factor on the connection, when the master can overtighten or not reach the nut, the lines with their use are not recommended to be hidden in the walls. The location of the pipeline in an open space is more convenient in terms of maintenance and operation: the compression elements are removable, if necessary, they can be easily twisted to increase the tightness of the connection.

Another option for connecting the line is using special glue. It is suitable for parts that do not have the required mating elements. Bonding is also carried out in several stages:

- Before connecting pipes with fittings, you need to process their edges. This can be done with a special knife that eliminates all irregularities.

- Remove dirt and grease with acetone or solvent.

- Apply adhesive and connect the pipes with fittings. In this case, it is necessary to maintain the pressure for a minute.

The use of the pipeline is allowed after several hours so that there are no breaks or leaks.

One-piece molded plastic fittings are mounted in the pipeline by soldering under heat. Welding systems are used to create heating and plumbing systems with different volumes of water supply. It is possible to do this with your own hands using a special soldering iron. They heat the docking ends to the required temperature. After connecting and cooling down, the two elements will become a single one-piece unit. In the case of metal counterparts, you usually have to call a welder.

There are a large number of different types of fittings used for the installation and installation of water mains. It is important to choose the right type that suits your needs, taking into account the cross-section and material of the pipes.