The capacity for accumulating liquid in the water supply system is the most important element after the pump, so its choice must be taken seriously. There are many different versions of this unit to make it convenient for people to use the water supply. The selection criteria are based not only on the volume of the accumulator, but also on the method of attachment, internal structure.

Purpose of the accumulator

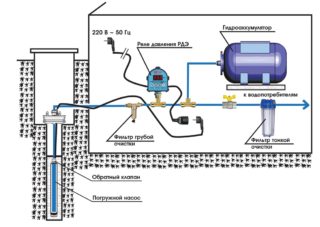

The main function of the accumulator is to accumulate liquid and maintain pressure in the water supply system. For this, this unit is equipped with a pressure gauge and a relay that maintain a certain interval, at the extreme points of which the pump is automatically turned on and off.

The hydraulic tank and the expansion tank should not be confused. The second is needed in the heating system to compensate for losses during the evaporation of hot liquid, as well as to take on excess air that occurs when water is heated in the boiler.

Water hammer is a dangerous phenomenon for plastic pipes. It arises when the liquid moves on the opposite side: the abrupt closure of the valve stops the flow, and it begins to move in the opposite direction, colliding with a wave coming from the pump. At a certain point, too much liquid accumulates in the pipe, which is capable of breaking plastic and even metal. The hydraulic accumulator restrains the formation of water hammer, since it is a buffer between the pump and the point of water consumption.

If the plumbing system of a private house is not equipped with a storage tank, this means that a powerful submersible pump or station will turn on every time someone opens a tap upstairs. The pump resource is limited by the number of on-off cycles, and also has an indicator - the maximum permissible frequency of switching on. On average, the equipment should be turned on 5 times per hour. Constant operation of the unit affects the details much less than frequent switching on. The hydraulic accumulator, due to the liquid reserve, allows to reduce the response rate by 2 - 3 times, therefore, its other function is to protect the electrical part of the pumping equipment from wear and tear.

If the electricity is suddenly turned off, residents can continue to use the water in the house as long as the pressure remains in the hydraulic tank. The principle of operation of a hydraulic accumulator for water supply systems is based on the balance of water and air inside the tank.

There are cases when a hydraulic accumulator is not only unnecessary, but can even harm the pump. We are talking about the constant operation of pumping equipment when watering the garden. In this case, the tank cannot be installed, since the equipment will often turn on and off. When watering, it is better if it works in a constant mode - this way the engine overheats and wears out less.

Residents can decide for themselves whether to install the tank or not, if the pump is equipped with a soft start system that prevents water hammer.

Application area

The accumulator can be installed not only in a private house, but also in a high-rise building, so that during a water cut in the city, residents have a small supply. This allows you to maintain pressure and use household appliances - a washing machine or dishwasher.

A hydraulic accumulator with a membrane resistant to hot temperatures is used in a hot water supply system as an expansion tank, so when buying, you need to clarify what function it will perform. A membrane for cold drinking water will not withstand boiling water. Rubber is also different - in the hot water supply it is technical, in the water supply system it is food grade. The hydraulic tanks are connected to a boiler and a double-circuit boiler.

In addition to household use, HA is used in many areas of industry, for example, in the engineering industry.

Types of storage tanks

For domestic needs, two types of tanks are used:

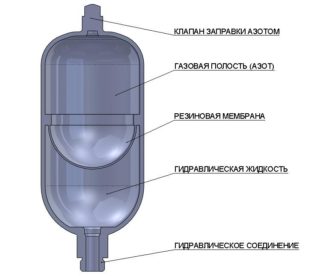

- Membrane. The rubber is secured in a retaining ring. In such a tank, the liquid comes into contact with the walls, but only in one half of the accumulator. The second half is occupied by the air mixture, which can be vented or pumped in as needed.

- Balloon. The liquid enters a rubber bulb attached to the neck at the entrance to the tank. The water does not come into contact with the walls and does not affect the metal. On the other hand, there is a possibility of pear bursting and liquid leakage through the nipple. In such a model, the membrane can be replaced.

There is also a version without a membrane, but for use in a private house in a water supply system, such a hydroaccumulator device is inconvenient. The air will mix in the tank and leave with the water, so it will have to be constantly monitored and pumped in. This should be done daily. Membraneless tanks are suitable for storing water for irrigation, outdoor showers.

Models of accumulators are produced in vertical and horizontal design. This is for convenience only. For example, in a small bathroom, the GA can only be installed horizontally under the ceiling by attaching it to the wall. If the technical room is located in the basement, it is better to buy a hydraulic tank with legs and bolt it to the concrete floor.

Principle of operation

The principle of operation of the GA is based on a change in pressure inside. This happens thanks to additional equipment - a pressure gauge and a relay. The incoming water flow fills the rubber bulb until the pressure rises to the specified level. Then the sensor is triggered and the pump turns off automatically. In the house, a tap is turned on and the liquid is used for household purposes until the pressure drops to the lower indicated level. The sensor is triggered again and the pumping equipment turns on. This is how a hydraulic accumulator works in a water supply system.

When the hydraulic tank is connected to the heating system, it is triggered when the pressure in the boiler rises due to steam during heating. Excess steam is sent to the accumulator, from where it can be vented if necessary. The heating system is losing fluid and pressure drops. In this case, the GA gives a signal to replenish the water so that the quality of heating does not decrease.

Accumulator device

The body is made of various materials - durable plastic, metal or stainless steel. Stainless steel is more expensive, so there are fewer such models on sale. Plastic is also not recommended - it can crack on impact.

The membrane is made of food grade rubber if it is intended for storing drinking water. There is also technical rubber if it is designed for other uses. The temperature regime of the membrane matters: in DHW systems, a heat-resistant one is installed, for cold water - ordinary. This must be taken into account when purchasing a replacement membrane.

A pressure gauge is a device for measuring and regulating pressure. Relay - a sensor that is triggered when the lower or upper limit of air compression is reached.

You can bleed air or pump in a new portion through the valve using a bicycle or car pump.

A coarse filter is installed in the body in case the water contains solid fractions - sand or stones. They can build up in the membrane and damage it. The filter is placed in front of the entrance to the rubber bulb.

Advantages and disadvantages of the hydraulic tank

Pneumatic accumulators have the following advantages:

- affordable cost;

- the ability to independently connect to the system;

- simple device;

- replaceable membrane;

- the ability to connect to any type of pump, as well as install several tanks in parallel, so that the operation of the water supply system does not stop in the event of a breakdown of one of the accumulators;

- the ability to select the GA of the required volume, but it must be borne in mind that the volume indicated in the instructions is the total number, the water in it will be 2/3 less;

- you can independently disassemble the structure and find a breakdown, as well as repair and replace parts without calling the master at home.

Among the disadvantages is the need for a separate room if the hydraulic tank is large and connected to a surface pump. Such nodes are usually very noisy, so they are isolated from living quarters. When purchasing an inexpensive hydraulic tank, frequent repairs may be required, which entails additional costs.

Criterias of choice

The next criterion is budget. Imported models are more expensive, but they are made of high quality materials from durable materials, the service life of which is longer. If you choose among domestic GA, you need to select not the cheapest ones, since they will work longer.

Having decided on the functions and budget, you can proceed to the technical part. Much depends on the quality of the wellbore fluid. If the source does not have a filter on the casing, it is necessary to buy a model of a hydraulic tank with a filter so as not to clog the water supply system.

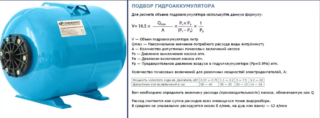

You should calculate the amount of fluid consumed by all family members per day and find out how much tank volume you need to install. You should provide a margin in case you need to purchase any household appliances or cut down a bathhouse. For a family of 4 living in the house, a 50 liter tank is needed. At the same time, the house has a washing machine, shower, bathroom and a tap in the kitchen. A specialist can calculate the optimal volume of HA using a special formula, which includes the maximum allowable number of inclusions, indicators of lower and upper pressure, maximum water consumption per hour.

It should be borne in mind that unused liquid stagnates and may smell of sludge, so a too large tank is not needed.

Installation and connection

You can use your own skills and experience to install. All connection stages are described in the instructions. The upper and lower pressure thresholds are preset. You can leave the factory settings, at which the lower limit is 4 bar, the upper limit is 8 bar. If the system does not work correctly, the settings are changed by twisting the large and small springs.

The tank is placed after the pump, connected using a fitting with three and five inputs. Two of them are for the relay and pressure gauge, the rest for pipes and flexible hoses to reduce vibration transmitted from the pump.

Before starting, using a pressure gauge, check the pressure of the air mixture inside again. Then you can turn on the system. If the relay is activated correctly, the installation process is complete and the plumbing can be operated.

Features of operation

During the operation of the accumulator, the following rules must be observed:

- check the pressure 2 times a year, if necessary - more often, pumping a new portion or bleeding off the excess;

- watch for leaks - they may indicate a rupture of the rubber membrane and the need for replacement;

- monitor the operation of the pump - its frequent activation also indicates that the accumulator is not working properly due to settings or breakdowns.

The less often the pump is turned on, the better. The maximum number of starts should not exceed 30 times per hour.

If it turns out that one hydraulic tank is not enough, you can build in one more or even more. In this case, the system will function if any of them breaks.

Service

The weakest point of the tank is the rubber membrane. In the process of work, it constantly stretches and contracts. If the air pressure inside is small, the rubber will stretch more, eventually causing it to burst. Then you have to buy a new one and change it yourself.

If the diaphragm ruptures, the pressure gauge will show sharp jumps and drops in pressure. When you press on the nipple, instead of air, water will flow from there. This means that there is no air left there, and the entire container is filled with liquid. Air mixed with water will come out of the tap in the house.

When replacing the rubber, make sure that its neck is tightly and evenly laid and fixed with a flange. If the edge slips off, water will leak out and the work will have to be done again.

Do not use sealant at the joints between metal and rubber. This leads to slipping and leaks due to a loose fit of parts.

Common malfunctions include nipple breakage when it does not close and releases air. The part can be purchased from a service center and replaced by yourself.

Prices for hydraulic tanks for water supply systems vary greatly depending on the manufacturer's brand. German, Italian, Swedish manufacturers have been working on the Russian market for a long time, supplying high-quality equipment. Domestic factories compete for them, the products of which do not differ in quality, but are somewhat lower in cost. You should not buy cheap goods made in China, as they are mostly unrepairable and do not last long. No spare parts are supplied for them, so the plumbing system can be idle for a long time.