According to statistics, 60 percent of breakdowns in water supply systems occur due to water hammer. It leads to a stop in the water supply and even to local flooding in the house. But with proper installation and operation of the highway, problems with its operation and the appeal to the court of flooded neighbors from below can be avoided.

The concept of water hammer in the water supply system

A water hammer is a shock wave propagating along the surface of the pipeline, as well as along the reinforcement elements. The destructive effect is obtained due to a sharp drop in pressure in the water supply system and the inability of water to compress.

A similar phenomenon occurs accompanied by various noises inside the pipeline, clicks, taps. If you do not attach importance to sounds, this threatens with serious consequences. Water hammer causes cracking and rupture of pipes, leading to breakdown of equipment and valves.

How does a water hammer occur:

- The fluid flow collides with an obstacle that appears in its path, for example, an airlock.

- Due to the high speed, the water layers are compacted, the dynamic head increases.

- The water cannot go anywhere because the pipe is sealed. An increase in the pressure on the walls of the water supply system entails its damage.

The manifestation of water hammer becomes noticeable at high rates of water flow in pipes, a strong pipeline of large cross-section and a sharp blockage of the passage in any section of the water supply system.

Causes of occurrence

The risk of a water hammer is maximum when the overlapping element of the internal water supply network is suddenly opened or closed.

Other causes of increased pressure in pipes:

- An airlock has appeared in the closed circuit of the network.

- Junk or the circulating pump is out of order.

- The pumping unit turns on and off uncontrollably due to power outages.

- Water enters the main line in excess of the norm.

A common cause of dynamic shock is the use of ball valves in the home plumbing. Their design does not provide for a smooth running, and the shutdown of the water flow occurs very quickly.

Dangerous consequences

In emergency situations, as a result of water hammer, the following suffers:

- Equipment - pipes will become leaky, shut-off devices will be damaged.

- Property - it will flood the room with a stream of water, which will cause damaged furniture and coatings - not only in your apartment, but also in your neighbors below.

- People - if a breakthrough appears in a heating pipe or hot supply system, there is a risk of thermal burns.

A ruptured water main that supplies water to an entire urban area is considered an emergency.

The extent of the damage largely depends on the area of the obstacle. If it is at the beginning of the water supply, the indicator of high pressure will be insignificant, but if at the end it will be much more.

How to avoid water hammer

Without changing the water circuit, the only protection against water hammer is the smooth closing of the shut-off element. If the tap is tight to close, it is permissible to move the handle in small jerks. This method can be applied to taps at home and at work.

It is possible to partially modernize the domestic water supply system by connecting pumping equipment with an automated control unit. A smooth adjustment of the pressure in the network is achieved by installing devices with an automatic change in the number of revolutions or with built-in frequency converters.

Comprehensive protection against water hammer in the water supply system of the apartment is carried out by the following methods:

- Installation of large diameter pipes. This helps to reduce the likelihood of water hammer. The speed of water advance in wide highways is always lower, in contrast to narrow ones.

- Inset of shock-absorbing elastic inserts in front of the overlapping element, expanding with increasing pressure, partly reducing it. To achieve the desired result, 20-30 cm long shock absorbers are enough. If the water supply runs for a long distance, the size of the insert increases by 10 cm.

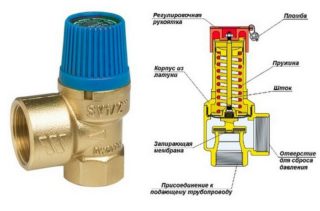

- Installation of a diaphragm-type safety valve. It is installed on the branch of the water supply line next to the pump in order to release a predetermined volume of liquid when the pressure rises.

Such a water hammer compensator in internal water supply systems is set in motion by means of an electric command from the controller or by means of a pilot rapid response device. The protective element is triggered when the head rises above a safe level, providing protection to the pumping equipment in the event of an unexpected stop. At the moment of excessive pressure increase, the regulator fully opens, and when the pressure drops to the permissible value, the valve slowly closes.

The use of accumulators as expansion joints also helps to minimize the consequences of a sharp increase in pressure in the water supply system to a minimum. The design of the unit is a metal casing with a rubber diaphragm located inside. In the event of a water hammer, the diaphragm part is displaced, due to which the hydraulic tank absorbs excess water. When the threat of a break in the water supply system passes and the pressure decreases, the diaphragm will return to its original position due to the air pressure on the other side.

A powerful water hammer in a hot water supply or heating network can be avoided by equipping a thermoregulation valve with a shunt - a narrow tube with an internal section of 0.2 to 0.4 mm, which is placed in the direction of movement of the coolant.

Shunting is used when arranging independent systems in which only new pipes were used. Rust and sludge in old piping will reduce shunt efficiency to zero. Therefore, when the tube is placed at the entrance to the system, it is advised to install efficient water filter elements.

Also, in networks where boiling water circulates, protective thermostats are installed. They monitor the pressure in the network and do not allow it to function after reaching a dangerous value. The unit is equipped with a spring mechanism that is placed between the thermal head and the valve. The spring mechanism is triggered at increased pressure, preventing the valve from closing completely. Installation of thermostats is carried out in strict accordance with the direction indicated on the body.

To avoid water hammer, it is important to regularly check the performance of all units and elements of the water supply line, clean and rinse the filtration devices. If the pressure drop and damage to the network occurred in the area related to the common property, repair work and compensation for damage must be carried out by the management company.