Sometimes there are mistakes in the choice of polymer water pipes that do not withstand low temperatures, or the pipeline cannot be laid to the required depth for technical reasons. In this case, the pipeline is heated using a heating cable that is connected to the mains. This technique is often used in regions with the coldest winter temperatures to avoid pipe bursting or water freezing inside.

The principle of operation of a self-regulating heating cable for a water supply system

If you put pipes in water, this will reduce the resource of their work. In such regions, soil movement is observed, which can deform or even cause cracks in the line. It is easier to dig a shallow trench and line the pipeline with heating cable.

In addition, there are potentially dangerous areas, for example, at the junction of internal and external water supply systems. Usually such a segment is located outdoors and requires serious insulation.

The principle of operation of a heating element is to receive energy and convert it into heat, which is transferred to the pipe. It can be used both for drinking water pipelines and for sewer mains. Autonomous sewage pipes are prone to freezing if they are located horizontally and do not have a slope. The presence of a fecal pump to accelerate the flow of liquids does not save the situation, since at night the pump does not work, and the drains inside freeze, which can lead to plastic rupture.

Heating with a cable is especially relevant if the line is located in the open air. Usually, this is how water is carried to settlements. The slope is not observed here due to the long length of the highway.

Device and types of cables

- The tape can be cut, while maintaining performance.

- If the elements overlap, they will not burn out.

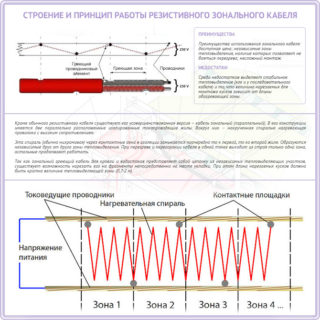

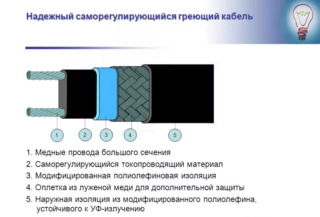

The principle of operation of a self-regulating cable is a constant temperature created by the heating cores. The conductors only conduct current, and the plastic element between them is heated. The higher the temperature of the plastic, the less heat transfer to the pipe, and vice versa, if the polymer starts to cool, it gives off more heat. During operation, the cable independently regulates the temperature. The service life is about 10 years, but it is expensive. If the issue of freezing of the water supply system is acute, it is not recommended to save money, since a cheaper resistive cable does not have such a working resource.

The principle of operation of a resistive cable is based on the ability of the metal to heat up and give off heat. In this case, the amount of heat is always the same. If it is -20 outside, there will be little sense from such a cable. It is only suitable for regions where temperatures rarely drop below freezing.

If during installation, lay resistive wires next to each other or accidentally cross them, most likely they will burn out from overheating. Another disadvantage is that you cannot use part of the coil of wire. If you buy a wire of a certain length, you must use it all, otherwise it will not work when cutting.

Resistive wires are single and two-core. The latter are more expensive, but they are bought more often, since this option is more convenient in operation. There is a plug at one end of the two-core wire, and the other is connected to the mains with a plug. A single wire is connected to the network on both sides, which is not always possible.

Components of any heating wire are:

- Internal veins - one or more. The larger the quantity, the greater the heat dissipation.

- Protective shell. Aluminum or copper shield and plastic insulation.

- Final sheath made of polyvinyl chloride.

After laying the cable on a water or sewer pipe, it is still insulated with mineral wool or other materials. In severe frosts, the heat from the cable may not be enough or a large power consumption will be required.

Internal and external cables

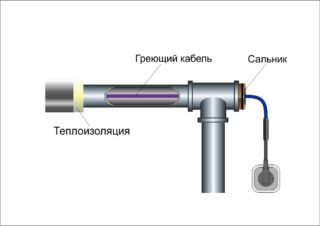

Heating cables are of two types - for installation outside or inside the pipe. These characteristics are prescribed in the instructions. Changing your location is prohibited.

The heating cable for the water pipe inside the pipe is suitable for products with a diameter of more than 40 mm, since the thickness of the cable will block the movement of water. Installation inside is more complicated, in addition, the surface material must meet safety criteria if it is used to heat a pipe with drinking water:

- The casing must be chemically neutral and not release hazardous substances into the water when heated.

- IP protection standards must be observed - at least index 68.

- The final casing must be completely sealed.

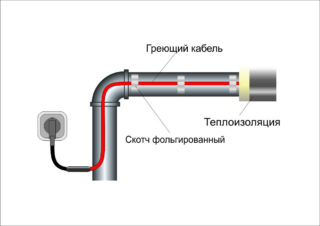

It is easy to lay the wire on the outside of the pipe. You need to reinforce it with plastic clamps or adhesive tape. It is important to observe the uniformity of the winding. To prevent the cable from heating the soil or air, it is covered with heat-insulating material from above along with the pipe.

Criterias of choice

When choosing a heating cable, the following parameters must be taken into account:

- Pipe diameter, especially if internal heating is planned.

- Insulation materials and thickness.

- Estimated heat loss.

- The region in which the pipeline is located. The farther north, the more powerful the cable is required, or you will have to select a serious insulation with a thickness of at least 30 mm.

In the middle lane, a power of 10 W / m is enough, in the northern regions it is necessary to buy from 17 W / m.

It makes sense to put a thermostat and a sensor so as not to pay too much. For example, resistive cables will work even when the outside temperature rises above freezing. A self-regulating cable for heating a water supply system usually turns off at +13 degrees, but if water is supplied from a well, its temperature will always be lower, even in summer. In autumn and spring, it makes no sense to heat water, which in the house still goes through the heating stage in a boiler or boiler.

The plus of the thermostat is that the cable will not work too long - it has its own definite resource and it will last longer. It is enough to set the regulator so that the cable is disconnected at a temperature of +5 degrees. Under such conditions, the liquid will not freeze, and the pipes are not in danger.

Installation methods

The first way is to lay the heating wire over the pipe. The work is performed at an air temperature above 15 degrees. After determining the length, the cable is first fixed at several points with adhesive aluminum tape. You cannot use ordinary scotch tape, as it melts when heated.The place of laying is usually chosen arbitrarily, but the masters advise from the side-bottom - for about 4 or 8 hours. After reinforcement with aluminum tape, the entire cable is glued along its entire length. This ensures a snug fit to the pipe.

It is possible to lay two cables in parallel, or in a spiral from one coil. Make sure that the cords do not cross - this will lead to overheating and damage to the system. After the heating wire is laid and reinforced, take polystyrene and fold both halves of it around the pipe, wrap it with electrical tape or tape. Polystyrene is the most durable material that is not afraid of moisture and tolerates temperature changes well. There will be no problems with it, unlike mineral wool, which crumbles after a year in the ground.

For internal installation, you need to clearly determine the length of the line to be heated. The main thing is not to damage the protective sheath of the cable. This method has many disadvantages, but if the pipeline is already laid in the ground, there is simply no other way to use the heating cable.

Do not pull the cable through shut-off valves.

Advantages and disadvantages of using different types of cables

- Maintains the same temperature regardless of the climate.

- Does not heat up and does not burn if several cables intersect.

- Can only be connected on one side.

- The flat shape increases heat dissipation.

- When cut a piece of the desired length, it retains its properties.

- The degree of isolation allows its use in a chemically aggressive environment, as well as in explosive areas.

The maximum temperature of the self-regulating wire is 65 degrees. Quality products never exceed this limit.

The resistive cable has one advantage - in price, as evidenced by the reviews of disgruntled owners of water pipes and sewers. Disadvantages:

- It is heated equally throughout the entire area - it does not matter that some area needs a higher temperature.

- If overlaps occur, the cable overheats at this point and the entire cable breaks down. The length should be accurately calculated so that you do not have to think about where to put the remainder. You cannot cut it off.

- Low efficiency.

In sales, the self-regulating heating cable is in the lead, since it has practically no drawbacks, and it is much more economical.

According to consumer reviews, those who put the wire inside the pipe later found that dirt had adhered to the winding, and in some places the clots completely blocked the movement of water. In some cases, the winding was exposed to corrosive substances in the liquid and dissolved. At the same time, the system ceased to function.

With external laying, the effect on the winding is completely absent, since the pipe is in the ground and is additionally protected by a polystyrene shell.

The price per meter of electrical cable for water supply depends primarily on the materials used in the manufacture. The number of cores inside also affects the cost. Cables of the following manufacturers are presented on the market: Germany, Ukraine, Poland, Czech Republic, Norway and Denmark. You can choose electrical cables for plumbing for any budget.

Consumer reviews

Novel: Once the water in the pipes froze, as the frosts were below 30 degrees. We sat on purchased eggplants for a week. In the summer we decided to install the cable. Since the pipes were already buried, it was necessary to do internal heating. We got through one season normally. On the second, the system stopped working and the water froze again. It turned out - I bought a cheap cable and it could not stand it. If you're really unlucky, then to the fullest. I had to carry buckets from neighbors again. Now I bought a German one, ripped open the pipes and stuck them on top. They advised to insulate - insulated. I'm looking forward to winter.

Evgeny: The winding was done at the time of laying water and sewage. The wire was stuck everywhere, since we live in Chelyabinsk. Everything was done by masters. 5 years have passed - no problem. I don’t understand why to buy cheap stuff for a serious business.

Novel: Eugene, we have here not only smart masters, there are no shops with a choice.I bought what was on sale, so I got problems two times.

Sergey: Tell me what to do. I already bought an internal wire, but changed my mind, because I worry that there is electricity in the water. Could it be attached outside?

Basil: You can't. They have their own characteristics. Better to sell or take back to the store.

Sergey: Well thank you. Isn't it possible to buy something cheaper, otherwise 22 m is almost 10,000 rubles? I saw a cable for a warm floor - 1500/22 m turns out.