More often, for the arrangement of autonomous water supply on the site, they mount their own source - a well or a well. Their depth varies from 15 to 25 meters (per sandy layer). The flow rate of such hydraulic structures is relatively constant. But sometimes it happens that water with fine sand comes out of the wells. This indicates a problem with the source. They need to be eliminated, otherwise in the future the mine will become completely silted up and become unproductive.

Reasons for the appearance of sand in well water

Experienced experts identify several reasons for the appearance of sand in water from a well. Each of them has its own location relative to the length of the casing.

Filter mesh problems

When installing the casing, its lower section must be perforated and covered with a special fine-mesh mesh. It serves as a filter. The following malfunctions may occur here:

- Breaking the mesh when installing the bottom of the column. In this case, sand will appear in the water almost immediately after the well is pumped. Its volumes will gradually increase in direct proportion to the flow rate of the source. The signs of a filter mesh rupture are sand particles of different sizes in the water - from the smallest to almost pebbles.

- Incorrectly selected grid cells. If they are too large and the grains of sand are very small, they will freely penetrate into the space of the casing and mix with the supplied water.

In case of problems with the filter, there are two options for changing the well operability:

- Too fine sand particles enter the source shaft through the large filter cells and settle to its bottom. Gradually increasing its layers, such a layer will completely fill the lower part of the sump and completely cover the filtering zone. The foreman will note a gradual and then complete decrease in the performance of a hydraulic structure.

- With a high aquifer, water will continue to ooze into the mine even with sand, but the owner of the source will find large volumes of foreign impurities in the liquid.

Due to highly contaminated water, the working units of pumping equipment, automation, and pipeline elements may fail. Therefore, you should not let such a problem take its course.

Depressurization of the casing

- Corrosion of metal under condition of incomplete make-up of pipe sections. If there are open areas of the thread with incorrect joining of two elements, under the constant influence of water, they rust and give a fistula. From this, the well can sand on any section of the pipe. On average, properly screwed columns last up to 50 years.

- Incorrect, not fully welded joints. Here, too, over time, holes appear through which groundwater with sand oozes into the source. Such phenomena are also bad in that, with particles of earth, not entirely clean water resources are mixed into the casing (with an admixture of nitrates, acids, precipitation absorbed into the soil). The average service life of welded columns is 20 years.

- Displacement of the casing relative to the limestone formation at artesian sources. This happens when the drilling technology and the installation of the string are violated.Only experienced specialists should drill and equip such deep hydraulic structures.

When the pipe is depressurized, it will be necessary to carry out complex repair work, which is better to be trusted by professionals. But if the casing has shifted relative to its axis in one of its sections, in most cases it will no longer be possible to save such a shaft.

Gravel backfill problems

If earlier the correct technology for installing the casing was considered to be the deaf welding of its bottom, today, instead of this, the lower part of the pipe is covered with a layer of gravel of different fraction. Further, the following may occur:

- The filter mesh first fully fulfills its function.

- Later, its colmatage occurs (dense filling of cells with grains of sand of various sizes). The filter just clogs.

- Since the water needs to find the entrance to the casing, it begins to wash away the gravel backfill with its pressure, swells it up and gives access to the casing for grains of different caliber.

Another cause of gravel backfill problems is an overly powerful pump located very close to the bottom. Such equipment draws in not only water, but also overcomes the resistance of gravel stones, gradually lifting them. As a result, over time, the mine opens up access to sand from the bottom. The layer can reach a level of several tens of centimeters, which will reduce the productivity of the well and lead to the appearance of dirty water.

Can I use a liquid with sand

Theoretically, such water is allowed to be used for economic purposes - irrigation of gardens and vegetable gardens, car wash, etc., but only after its high-quality mechanical cleaning. However, it should be remembered that the complete disposal of the liquid from the sand is a large cost for the installation of filtration systems, the need to use a drainage pump for pumping and lifting dirty water. Such expenses may be considered inappropriate. It is best to completely get rid of the sand in the well by taking appropriate measures.

Effective cleaning methods

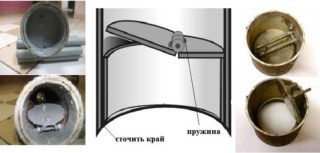

The easiest way to deal with a silted bottom is to use a thief: cutting a steel pipe with teeth on one side and special flaps in the same place. The principle of its operation lies in the fact that when free falling from a height of 0.6-0.8 meters, its weight cuts into the layer of sand deposits. At this moment, the flaps of the bailer open and the sludge enters the pipe cavity. When it rises, the blades close, preventing the return of dirt into the space of the casing.

As soon as the volumes of the lifted sludge are very low, a high pressure water jet should be applied to the bottom of the mine. This will help wash away any remaining dirt in the filter area. The dirty liquid is pumped out with a powerful pump until a clean water resource appears.

Wells up to 15 meters deep can be cleaned with a thief. With its greater length, the master will no longer cope with the problem.

Mechanical flushing

Here you need to use two pumps - one powerful for supplying water under pressure to the silting zone, the second drainage for pumping dirty liquid up. Both units must work at the same time.

The supply hose is equipped with a special weight so that it does not rise upward under the pressure of the incoming water. It is lowered about 20-25 cm from the silt layer. The intake hose is placed a little higher (30-40 cm from the bottom). Both pumps are turned on and work begins. The incoming liquid will break up the sludge and the sump pump will pump it up.

It is advisable to prepare a special barrel or other reservoir for dirty water. A bucket without a bottom is attached to its upper edge, covered from below with a fine-mesh net. Water will pass through such a homemade coarse filter and be cleaned of grains of sand.

Periodically, the drain pump must be turned off and flushed out of accumulated dirt.

Use of special equipment

If the well drives sand, a special technique can come to the rescue - a fire engine.Renting equipment will cost a pretty penny. But the work can be done in half an hour.

The principle of operation is that the operator will feed large volumes of water into the well through the fire hose, and with his help pump out the liquid contaminated with sludge.

Preventive measures

So that the well does not produce sand over time and does not cause trouble for its owner, it is important to take a number of preventive measures.

- Fully swing (flush) the source after drilling it. It is important to do this until the water runs completely clean.

- Correctly calculate the fraction of the cells of the filter mesh by the size of the grains of sand. Experienced professionals can do this.

- Observe the strength and reliability of all connections of the casing during its installation.

- Use the pump that matches the performance of the source in terms of technical characteristics. A too powerful unit will either deplete the well or drive the sand.

- Operate the waterworks regularly (even in winter). Seasonal downtime leads to silting of the filter. If it is impossible to avoid seasonal well operation, it is advisable to come to the site once a month and pump out at least 100-150 liters of water.

A problem is always easier to prevent than to solve it later.