As a rule, an autonomous water supply system is the only way to ensure comfortable living in a country house. If there is a well on the garden plot, you can enjoy the taste of crystal clear water, which has not covered kilometers in the outdated central highway. But sometimes it is problematic to realize what was conceived, due to the great depth of the water reservoir. A pumping station will help to solve the problem, an integral part of which is a pressure switch for a hydraulic accumulator.

What is a pressure switch

To adjust the water pressure switch in the accumulator, you need to familiarize yourself with the principles of operation and device design, as well as the rules for setting it up.

Maintaining a constant pressure in the pipeline allows the optimal level of the water column in the well shaft. Responsible for this are two parts attached to the water pump - a pressure switch and a hydraulic accumulator. The relay is a small box containing electrical contacts. The water accumulator has a cylindrical shape and is designed to store a fixed volume of liquid.

There are several modifications of pumping equipment. The pump can be installed directly on the accumulator, a pressure switch is already connected to it using an adapter called a five-piece. Separately, the five-piece is equipped with a pressure gauge; its panel displays the pressure inside the system.

The principle of operation of the pumping system boils down to the fact that the relay is equipped with contacts that are triggered when certain pressure levels are reached.

Without a pressure gauge, it is almost impossible to set up a relay for a hydraulic accumulator. Also, the initial filling of the accumulator with water should be carried out gradually, otherwise there is a high probability that the pear (membrane) will be damaged. This is due to the fact that as a result of long-term storage of the liquid, its walls stick together.

Types of pressure switches

There are miniature and large enough devices. They also differ in the equipment with additional functions. A classic relay for a hydraulic accumulator includes two working units:

- hydraulic;

- electric.

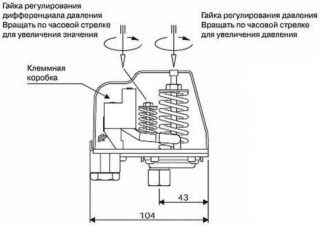

The first is intended for the interaction of the device with the liquid supplied to it. It consists of a stem and two springs. Due to the latter, the optimal pressure parameters are adjusted. The main task of the latter is to connect conductors to electricity. It is a metal terminal block with clamping screws. Depending on the position of the hydraulics, the terminals open and close.

On the market or in specialized stores, you can purchase the following types of pressure switches:

- with dry running sensor;

- mechanical;

- equipped with a built-in pressure gauge;

- electronic.

Electronic relays are equipped with additional modules that open and close contacts. They also have built-in electronic pressure gauges with a digital display. The dry-running sensor warns the pumping station to work "idle" if, for example, the water level has dropped, the intake hole is clogged, or the supply pipe has been damaged.

Pressure switch setting rules

The pressure switch needs to be adjusted during commissioning and after repair, as well as when making changes to the autonomous water supply system. Before proceeding with the setup, you need to familiarize yourself with the following rules and recommendations:

- Warn all residents of the house not to use taps, showers, toilets and other water points during repairs.

- Close all taps and check the integrity of all plumbing elements, pipes, taps, etc. Pay special attention to the toilet cistern. If it leaks or continues to work, it will be almost impossible to properly adjust the operation of the device.

- The working air pressure in the water accumulator is subject to mandatory check. If the readings fluctuate or are below normal, you need to restore the relay to the factory settings.

If difficulties arise during the work, it is better not to experiment, but to contact a specialist. If the entire autonomous water supply system fails, a lot of capital investments will be required to restore it.

The main task of the relay is to control the minimum and maximum pressure indicators in the storage tank, to maintain the optimal pressure difference when the pumping station is turned on and off. The limit of permissible values depends on the power and performance of the installed pump and the hourly flow rate.

In the technical data sheet of the equipment, all the characteristic features of the factory setting are indicated. 1 - 5 atmospheres are standard values for setting the pressure switch in water supply systems. Starting indicators - 1.5 atmospheres. The parameter for the comfortable operation of the pumping equipment engine is 2.5 atmospheres. The maximum pressure at which all equipment is turned off is 5 atmospheres.

If the parameters set by the factory have become irrelevant or a failure has occurred in the operation of the system, the adjustment is made independently using a pressure gauge. This measuring device is installed on the accumulator manifold. Correction is made based on the readings of the pressure gauge after the pumping equipment has been turned off. The pressure surge is created by opening the water tap.

Step-by-step adjustment of a water supply accumulator with a pressure switch and a manometer

The adjustment is carried out under pressure, you should not disconnect the pumping station from the electricity beforehand. The pump must fill the entire storage tank with liquid, thereby increasing the pressure in the pipeline network. As soon as the relay has triggered and the pump is turned off, you need to remove the plastic cover from the housing and loosen the tension of the small spring to the maximum.

The relay is adjusted to the minimum pressure for switching on the pump as follows:

- During operation, only the large adjusting spring will be involved.

- The jam nut must be rotated clockwise to increase the starting pressure.

- The loosening of the tightness provides a decrease in the actuation pressure of the accumulator relay and turning on the engine of the pumping equipment.

- To check the work done, you need to open the water tap and drain the water until the pump turns on.

The accumulator relay is adjusted according to the pump shutdown pressure according to the following algorithm:

- During operation, only the small adjusting spring will be activated.

- To increase the pressure difference, the nut on the small spring pin must be tightened well.

- The tension is released by reducing the pressure to turn off the pumping station motor.

- The result of the changes made to the settings is checked by a test run of the water pump.

If the results of the check show that the readings of the pressure gauge coincide with the required values for turning the engine on and off, the adjustment is completed.If you could not configure the device yourself, it is better to contact a specialist competent in these matters or purchase a new relay. If a decision is made to purchase a new "box", it is important when choosing to pay attention to the compatibility of work with an autonomous pumping station and methods of connecting to the electricity network.

The accompanying operating and setting manual contains detailed diagrams and descriptions of how to connect and adjust the relay. Most often, difficulties do not arise.

The lack or absence of air entails the expansion of the diaphragm and the operation of the equipment with each intake of fluid. Increased pressure reduces the volume of water in the membrane, as well as the interval between the actuation of the pressure unit. Frequent switching on and off of the water pump leads to overheating, the operating life is significantly reduced.

Preventive actions

If the system is malfunctioning and the pressure gauge readings confirm this, the following preventive measures are taken:

- Parts that are sensitive to mechanical stress are checked and, if necessary, adjusted.

- It is recommended to clean the contacts.

- If the relay does not work, do not rush to disassemble it, it is better to knock on the case with a light object. Experts note that such manipulation often helps.

- Once a year, the moving parts of the device are lubricated with grease.

- If you tighten and tighten the adjustment nuts, the relay will not work at all. This is a common mistake.

The installation price fluctuates in a wide range, the minimum cost in all regions of Russia does not exceed 1000 rubles. Electronic modifications are more expensive as they provide more accurate data.