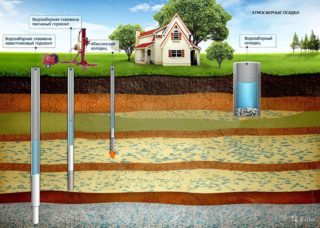

Autonomous water intake structures in the country or in a country house over time silt up and clog up with sand, which leads to a decrease in the efficiency of water supply and a deterioration in water quality. An economical solution to the problem is to clean the well from contamination on our own. But it is important to find out the reasons for silting and sanding, eliminating which you can significantly increase the interval between procedures.

The main causes of clogging

Most often, the prerequisites are laid even at the stage of construction. For example, contamination can occur due to a leaky head, a caisson.

Other causes of clogging include:

- improperly selected filter - grains of sand and fragments of organic matter seep through large cells;

- insufficient pumping of water - there is a constant settling of particles of silt and clay to the bottom;

- the use of rotary-type pumps at great depths - if the indicator is more than 10 m, they cannot cope;

- lack of protection against debris entering the mine from the surface;

- untimely maintenance of pressure equipment and cleaning of filter elements;

- changing the direction of subsurface sources.

And if the last problem can be dealt with only by drilling a well in a new place, all the rest are solved by reconstructing the units of the water intake unit, replacing the filter or pump, and timely pumping out.

If the owner of the site does not have the opportunity to systematically pump out water throughout the year, this should be done more intensively in the summer. The increase in the number of procedures reduces the need for cleaning the mine.

Self-cleaning methods for silt and sand

There are many ways to clean a downhole rig with your own hands, but any of them refers to three technologies: flushing, pumping, or purging.

Pumping out by pumping device

Do-it-yourself well cleaning with a vibration pump is one of the simplest methods. Lower the pressure device to the bottom and start it. All particles of debris that have accumulated at the bottom of the mine will rise and be discharged outside.

This process is not fast, since there is a strong heating of the pumping unit casing from long operation, and the device must be stopped from time to time. You also need to periodically run clean water through the system.

The use of vibration pumps is possible only in water intakes with a depth of 10 meters. You can also clean the well with an ordinary pump if the water layer does not lie deeper than 40 meters.

Flushing by pressure equipment

There is one more method with the use of pressure equipment, but technologically it is flushing. This will require two pumps. Do-it-yourself flushing of the well from sand is carried out using the following technology:

- A deep pressure unit with a lower water intake is lowered to the bottom. It is needed to pump out the liquid.

- The second pump is used to supply an aqueous stream that agitates the deposits. The liquid can be supplied both from a pre-filled container and from another water supply source.

- With a constant supply of fresh water, the well structure is flushed out - all suspensions, even those fixed on the walls of the mine, are separated and removed to the outside.

The hose used for drainage must be systematically shaken to avoid damage to the pump.

Using the bailer

Self-cleaning of the intake structures can be done with a thief. This technique is used if the pollution is not too strong, and the depth of the mine is up to 25 meters.

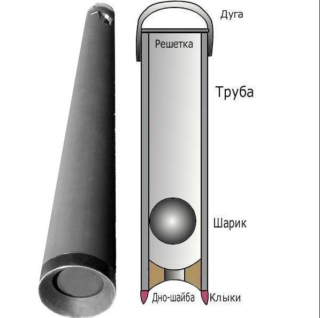

A bailer is a pipe section on a cable with a net and a ball inside.

The pumping itself is performed in this way:

- The device is directed to the bottom, and then raised to a height of 50–70 cm and dropped sharply.

- Water enters the inner part of the pipe under pressure, and the ball first goes up and then down and closes the hole.

- Such actions are performed several times.

- Then the device is pulled out of the mine and cleaned from dirt.

In one approach, you can fish out about 0.5 kg of sand and silt. By performing cleaning by this method, the rate of clogging of the well is determined.

You can create this simple device with your own hands or buy it at a hardware store. It should be noted that one person alone will not be able to cope with the work. You will need a winch and at least two adult men.

Purge of the intake structure

The cleaning process by means of a compressor requires constant monitoring. The blowdown is stopped at the moment when the water outlet has stopped.

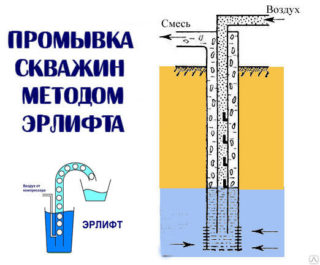

If the well is deep, it is better to use an airlift for purging - a specialized pneumatic lift that uses compressed air or industrial gas.

Chemical method of cleansing

If the previous methods practically did not increase the flow rate of the well, then the filters are covered with solidified ferruginous and lime suspensions. If it is impossible to replace them, it is worth resorting to extreme measures - acid cleaning. This option implies the filling of battery acid used for vehicles at the bottom of a well emptied by a pump.

The outlet is tightly closed with a plug and the intake structure is left for a couple of days. After that, water is pumped out several times. Even after these procedures, it is not suitable for drinking and cooking for a month. The liquid is taken only for technical needs.

The more pumpings are performed, the sooner acids will be washed out of the well. But before consuming water, it should be tested in a laboratory environment to confirm its safety.

Method selection criteria

When choosing a cleaning method, be sure to consider:

- the depth of the intake shaft;

- availability of suitable equipment;

- the number of people who can participate in the cleansing process.

Well structure cleaning can be done much faster if there is no filter element. This allows the equipment to be lowered to the very bottom for work.

Preventive measures

It is almost impossible to prevent siltation or clogging of the well with sand, since subsurface sources all the time bring with them organic and inorganic fragments. But it is necessary to take measures to reduce pollution.

The first step is to secure the well from outside debris from entering it. To do this, you will need to close the exit of the mine, for example, with sheet metal, plastic and wooden covers. Such coatings are easy to make yourself, but you can find suitable items on sale.

It is possible to extend the operating life of a well by following a few simple rules of use:

- Drill in accordance with the technological rules, and upon completion, immediately flush the shaft until the fluid is completely cleaned.

- Check if the casing has lost its tightness and if the filter element is not damaged.

- Clean the filtering device regularly, and if it gets worn out, replace it.

- Protect the source from surface water and pollution by means of a caisson, a head. It is possible to seal the top of the casing, but this is a temporary solution.

- Select the appropriate pressure equipment based on the flow rate of the source. It is not recommended to use a vibration pump for pumping. In the process of vibration, there are always mini-falls of sand and organic compounds. This technique is best used for cleaning.

The well cannot be left without water intake. The ideal operating mode is the daily intake of several tens or hundreds of liters of liquid. It can be provided with permanent residence in the house. If for some reason this does not work out, it will be necessary to systematically, at least once every two months, take at least 100 liters of liquid.

Even properly carried out preventive measures are not an absolute guarantee that it will be possible to avoid contamination of the water intake source. They only contribute to increasing the intervals between cleaning. A well-equipped well is cleaned twice a year, and an uncompleted well - up to several times per season.