To protect the autonomous source from debris getting into it, to correctly place all pumping equipment near the mine, to prevent the water from freezing in the column, you need to do the well construction with your own hands in a timely manner. There are several options for upgrading a hydraulic structure. Each of them has its own pros and cons.

How to equip the source

Regardless of which well on the master's site - artesian, sandy, Abyssinian - one of three options for arrangement can be applied to it.

Source location in the house

At first glance, the easiest way to protect the source from cold, debris, vandals. But only if we are talking about drilling a well before building a house. Drilling inside a finished basement or cellar is technically difficult and costly. An exception is the Abyssinian spring, for which a pipe is simply driven into the ground to a given depth.

The advantages of the location of the source itself and the necessary equipment in the house:

- All accessories for the well and the top of its casing are warm. There is no need to insulate the water supply, to bear the costs.

- The minimum footage of the pipe required for the installation of the line.

- Savings on the purchase of a powerful pump, which must transport water to long horizontal sections, provided that the well is located on the street.

There are also a number of disadvantages:

- High humidity from the basement side. Risk of mold spreading around the house in the future or the need to thoroughly waterproof the basement.

- Regular noise from a pump running or soundproofing work.

The most important disadvantage with the internal location of the source is the impossibility of using special equipment for repair work or plugging the source. Sooner or later, such activities will be required.

Aboveground house

Using this method, you can equip a water well with your own hands. The solution is design-interesting, but more expensive than installing a simple caisson. More consumables will be required for the construction of an overhead house.

Structurally, the house is a structure deepened in its lower part. All working units are located below the freezing of the ground, as if in a cellar. The upper part of the building can act as a shed for storing household equipment.

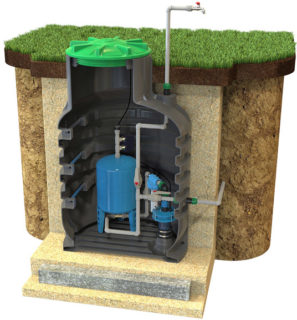

Caisson

The most optimal option for arranging the upper part of the casing. Structurally, this is a chamber of approximately 1x1 meter and a depth of 1.5-2 m, which is located in the ground around the casing. Thus, the pit is an air gap that protects the source from the effects of subzero temperatures. Such a structure does not spoil the landscape design. If the caisson hatch cover is interesting to finish, it will add zest.

You can build a camera with your own hands from reinforced concrete rings, brick or concrete. There are ready-made factory-made polymer caissons on sale.

Required tools and materials

To erect a caisson and improve a water well, you need to prepare the following tool:

- shovel (bayonet and shovel);

- rammer;

- concrete mixer;

- tape measure and building level;

- puncher;

- nails, hammer;

- hacksaw.

Of the materials you will need:

- cement grade M-400;

- river sand;

- crushed stone of the middle fraction;

- formwork boards;

- reinforcing mesh;

- brick blocks or reinforced concrete rings (if the caisson will be built from them);

- sealant (roofing material, bituminous mastic).

The initial stage of installing any caisson is earthworks and foundation preparation. Immediately you need to dig a hole around the casing 1x1 m and a depth of 1.5-2 m (plus 30 cm on each side). The bottom is well rammed. If the installation of a polymer caisson is envisaged, you can fill in a 10-15 sand cushion and compact it. If the installation of the camera is made of concrete, brick, reinforced concrete rings, you will have to fill in a monolithic base.

A layer of mortar prepared from a mixture of cement, sand and gravel in proportions of 1: 3: 5 is poured over the sand cushion. The mixture is brought with water to the consistency of thick sour cream. The concrete pad can be reinforced with a reinforcing mesh.

Forcing the walls of the caisson

If the protective chamber for the well is made of reinforced concrete rings, you will have to hire special equipment. Each ring is lowered with a crane to the bottom of the pit so that it becomes even. The joints between the rings are carefully foamed and coated with sealant.

Using a perforator, side technical holes are made for the outlet of the pipeline. All gaps are sealed with sealant. The caisson roof can be made from a concrete slab with a top hatch.

When installing a brick caisson, the laying of blocks begins from the corners. Previously, under the walls you need to lay sheets of roofing material. At the masonry stage, it is important to immediately provide for technical clearances for the outlet of the line from the chamber.

The finished caisson is plastered on both sides. After the solution has dried, the walls are coated with bituminous mastic.

When forcing monolithic walls, you first need to install the formwork. It is mounted to its full height from wooden panels or in stages from boards of 30 cm. The solution is poured, carefully ramming it. The walls of the monolith caisson can be reinforced with reinforcement.

After the concrete chamber is completely dry, technical side holes are made using a perforator with a crown. Then the walls from the outside must be thoroughly smeared with mastic.

When the caisson is ready, it is backfilled. In this case, the soil must be thoroughly tamped in layers. Instead of ordinary earth, it is recommended to use a cement-sand mixture.

Plastic caisson device

If the master decided to leave the polymer chamber, the source arrangement diagram looks like this:

- A round hole is made on the side of the bottom of the tank. Its diameter should correspond to the section of the casing.

- The caisson is put on the column and lowered to the very bottom of the pit.

- With the help of a hacksaw, lateral technical gaps are formed and the main pipes are removed. Joints, open areas need to be thoroughly covered and sealed.

The installed polymer caisson is covered from the outside with soil or a mixture of cement and sand.

Equipment installation

In order for the well to work smoothly and fully, it remains to install all the components of the pumping equipment. Here you need to prepare the following elements:

- Submersible submersible pump. Especially relevant for artesian wells.

- Check valves, drainage and shut-off valves.

- Coarse filter.

- Hydraulic accumulator with a volume of 25 liters or more. The more people live in the house, the larger the tank should be.

- Pressure gauge and pressure switch. With their help, you can adjust the optimal parameters of the station's performance.

All components must be connected in series with each other. Running the station dry is strictly prohibited. Therefore, you must first fill the accumulator with water through a special technical hole. At the first turn-on, the pressure indicators are adjusted in the range from 1.5 to 3 atmospheres (lower and upper values). This is enough to provide a thirty-meter water pressure.

A properly equipped well means an uninterrupted supply of water to the system, the absence of the need for complex repair work.

If it is necessary to equip the summer version of the source, you can simply put a head on the top of the column.