The installation of the water supply system must be carried out in accordance with the established standards. In this case, special attention is paid to the choice of pipes. Their technical characteristics ensure long-term operation of communication in certain conditions (hot / cold water supply, heating, etc.). More often, craftsmen give preference to metal-plastic or polypropylene pipes for water supply. Both materials have a number of characteristic features.

Comparative analysis of water pipes made of metal-plastic and polypropylene

Specifications

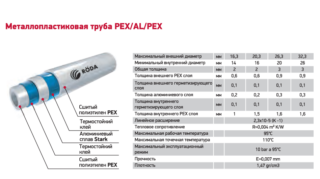

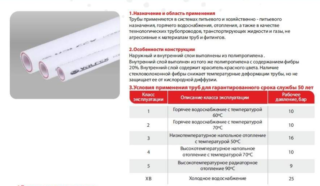

Metal polymer pipes due to their structure (plastic / glue / aluminum foil / glue / plastic) have the following capabilities:

- permissible maximum temperature of transported media - +110 degrees;

- the length of one pipe cut is from 50 to 200 mm - this gives the craftsman the opportunity to mount the system with fewer connections and fittings;

- working pressure - 10 atmospheres at a temperature of +95 and 25 atmospheres at rates up to +25;

- high thermal conductivity, which is especially good when installing a heating system in the house;

- long service life - subject to correct installation, metal-plastic serves for more than 50 years for cold water, for hot water - up to half a century;

- good plasticity - the permissible level of bending is up to 90 degrees.

The tubes have a perfectly smooth surface of the inner walls, which prevents clogging and silting of the communication.

- The limiting operating temperature of the pumped-over medium is +95 degrees;

- service life - 25 years for the hot water supply system and from 50 years for cold water supply;

- working pressure - 25 atm at temperatures up to +25 degrees, 7 atm at rates from +25 to +95 degrees;

- high-quality reinforcement of pipes, which allows them to be laid under the tiles in the bathroom.

Polypropylene tubes are afraid of ultraviolet radiation, so they are only suitable for interior work. Do not use them at a constant room temperature below 0.

Installation and connection

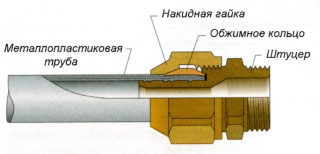

In any case, with temperature and pressure drops in the system, the metal-plastic is exposed to expansion / contraction. This leads to loosening of the fittings over time. As a result, there may be a loss of tightness of the joints and the occurrence of leaks.

Installation of polypropylene is performed by soldering. The process is simple, even a non-professional can handle it. The main thing is to get a special soldering iron with nozzles of the right size. The welded joints have increased tightness. Turns in the system are formed using special fittings-adapters.

Maintenance and repair

It is better to operate pipes made of metal-plastic in such conditions:

- warm rooms with temperatures from +5 degrees;

- fire hazardous facilities;

- systems of the same type (or only cold water supply / hot water supply, or a heating system) - if the metal-plastic is subjected to temperature fluctuations from the inside, its service life is reduced by three to four times.

It is also important to remember that icing in the system can lead to pipe rupture. As for the maintainability of the metal polymer, if one tube or connection fails, the entire communication will have to be changed, since the tubes change their plasticity over time along their entire length.

Polypropylene pipes cannot be used in such conditions:

- open sun;

- subzero temperatures;

- objects with a high fire hazard.

In case of failure of the PP pipe (which happens extremely rarely), you can simply replace the deformed section without the need to change the entire communication.

Advantages and disadvantages

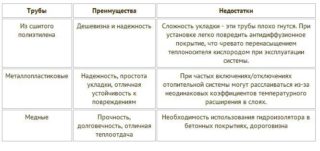

The main positive aspects of metal-plastic pipes are:

- Moderate ease of installation. The work can be done even without special skills.

- Plasticity of the material. Pipes lend themselves to bending.

- Internal smoothness of the walls, which is maintained regardless of the transported medium and its temperature.

- High level of thermal conductivity due to the foil layer.

Cons of metal polymer:

- small range of sections (from 16 to 63 mm);

- relative fragility of the material - lack of resistance to shock loads, ultraviolet light;

- tendency to rupture when frozen;

- the risk of weakening joints during temperature fluctuations;

- the relative high cost of the pipes and fittings themselves for installing the system.

- increased wear resistance: impacts, mechanical influences do not harm the polymer;

- the integrity of the polypropylene structure is not violated over time due to the reinforcing fiber - no delamination is observed;

- the plasticity of the polymer allows it to expand / contract many times under the influence of the temperature of the transported media and again return to its original state without the risk of deformation;

- inertness to aggressive media - polypropylene can be placed on the line for transporting compounds with acid impurities;

- the ability to hide communication under tiles, behind drywall, in concrete.

The disadvantage of propylene is its inability to bend during installation. Experienced craftsmen can easily work around this problem with special swivel fittings. Under the influence of ultraviolet radiation, polypropylene is destroyed over time, therefore it is not used for outdoor work.

Which pipes are best for plumbing

If we take into account all the technical characteristics of both materials, take into account the positive and negative points, the conclusion is as follows:

- Reinforced-plastic pipes are a good option for installing a heating system. The structure of the metal polymer will give off heat to the room. In addition, the operation of the material at a constant temperature prolongs its life.

- Polypropylene pipes are as good as possible for arranging a water supply system in a house or apartment / cottage, but not on the street.

For the correct installation of the water supply or heating system, it is better to use the services of a professional master. Accurate joining extends the life of the system. The tightness of the pipeline in the hands of the master will be the best.