The comfortable life of a modern person is impossible without running water. The correct choice of the diameter of the pipe for water supply in a private house will help to avoid troubles and breakdowns caused by improper operation or insufficient throughput of water supply and drainage systems.

Criteria for choosing the diameter of a pipe for a water supply system in a private house

Pipe section is a criterion for calculating the throughput of a pipeline system. For example, a water pipe with a diameter of 32 mm is capable of passing 50 liters per minute, and with a section of 25 mm - only 30 liters. It is also worth considering the fact that the mixer cannot provide a flow rate of more than 5 l / min.

It is recommended to select a suitable cross-sectional size for rolled pipe using the following criteria:

- total length of the water supply network;

- number of water consumption points;

- temperature of the transported liquid;

- number of turns and joints;

- presence / absence of pressure drops in pipes;

- planned volume of water consumption;

- material for the manufacture of plumbing elements;

- type of water supply: centralized or local.

The first two criteria have a directly proportional effect on the size of the diameter. With an increase in the total length of the pipeline and the number of points of water consumption, the cross-section of the pipeline should also be taken large. The main points of water consumption are the heating tank, toilet bowl, sink, sink, shower or shower cubicle, bathroom, washing machine and / or dishwasher, etc.

The third point draws attention to the fact that polymer structures for supplying / removing cold and hot water differ in wall thickness. The hot liquid is transferred in thick-walled pipes. Metal structures can be used with the same thickness.

When creating a system with frequent joints and turns, as well as in case of uneven water pressure due to multi-storey buildings and indirect water movement, it is necessary to use pipes of an increased internal size. You should also choose elements of a larger section if a large number of people live or stay in the house.

The material chosen determines the future cost of the entire system and the degree of difficulty in assembling it. Methods for calculating pipe capacity found in the technical literature are usually only suitable for metal products (usually steel). Their peculiarity is that the inner diameter gradually changes during operation. This is due to limescale and other deposits accumulating on the walls in one or more layers. Pipes made of polymeric materials (plastic, polyethylene, metal-plastic, PVC) cope well with this problem. However, they can expand when exposed to hot temperatures. This leads to a drop in head, noises and malfunctions. Copper elements last longer than steel and polymer ones, but have a much higher cost.

When connecting to a centralized water main, you need to select the cross-section of the pipes only for routing them around the house. If we are talking about an autonomous option, the costs of constructing a well or drilling a well are additionally taken into account. In the future, the funds spent will be compensated for by independence from external factors and the absence of a constant payment for water supply and sewerage.

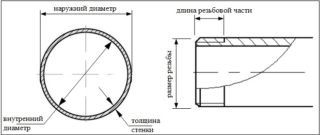

Pipe diameter designations

The outer diameter is denoted by Latin letters D or Dн, inner - in letters d or Dvn, and wall thickness - lowercase or uppercase s... The standard does not specify the inner diameter. It can be calculated by subtracting twice the wall thickness from the external dimension.

There is also the designation Du (DN, Dn), which is used when specifying the nominal diameter (passage) of the rolled product. In the reference literature, there is another name for this concept - "nominal pipe diameter". This is the average size of the product of pipeline rolled products (through clearance), which usually differs from that indicated on the marking. It is obtained by rounding the measured inner diameter to the nearest standard value. For example, for pipes with outer and inner sections of 156/144 mm and 156/148 mm DN = 150 mm.

Steel products are marked in inches, and copper, aluminum and polymer - in millimeters. To correlate these dimensions with a combined piping system, use special tables or programs (applications).

Correspondence of inches to the nominal diameter of the pipe: ¼ inches - 8 mm; ½ "- 15 mm; ¾ inch - 20 mm; 1 inch - 25 mm; 1¼ inch - 32 mm; 1½ "- 40 mm; 2 inches - 50 mm; 2.5 inches - 65 mm.

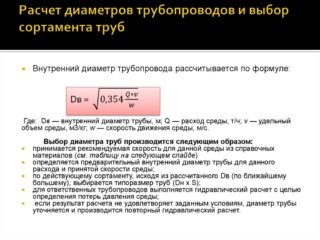

How to calculate the cross-section of water supply pipes

- The length of the network is less than 10 meters, the required pipe diameter is 20 mm.

- For pipes with a total length of 10-30 meters, the cross-section of the water supply system is taken to be 25 mm.

- For networks with a length of more than 30 meters, it is recommended to use pipes with a diameter of 32 mm.

Moreover, the length of one pipe varies from 4 to 15 meters. The elements of the pipeline must be of high quality and reliable in order to ensure the long-term operation of the water supply system without failures.

Throughput is a parameter showing the ratio of the limiting volume of liquid passing through the pipe section per unit of time. There are three ways to calculate it:

- According to technical formulas. Average values are applied. Formulas are quite complex and require precise substitution of all data. Therefore, they are practically not used.

- According to the tables. A fairly simple and accurate solution to a hydraulic problem. Contain dependencies between various parameters. In particular, the dependence of the pipeline throughput on the inner diameter.

- With the help of special software. Based on the initial data, the program automatically performs the calculation taking into account all connected equipment. Substituting the estimated inner diameter, resistance in elements, roughness index, total length of the pipeline, the result is displayed almost instantly.

If the water supply system has a length of 30 meters or more, there are many turns, branches and butt joints on it, a larger diameter is selected.