In addition to steel, cast iron and plastic pipes, copper is used in water supply systems. This metal has several distinct advantages, but differs in cost. It is possible to make a plumbing from copper pipes, as well as install taps and other fittings made of copper, if there are no restrictions on the budget for repairs.

Metal specifications

Copper is the very first metal that ancient people mastered. They made dishes and weapons from it. This material is soft in consistency, has antibacterial properties, so drinking water from copper dishes is considered safe. When in contact with copper, viruses, bacteria and fungi are killed. It is helpful to wear a copper bracelet to stimulate the thyroid gland. According to the Ayurveda recipe, it is recommended to leave the water in a copper vessel overnight and drink it in the morning.

In plumbing systems, copper compares favorably with its competitors - steel and plastic. It can withstand thermal fluctuations up to 250 degrees, does not change its characteristics when freezing - in the cold it becomes plastic and durable.

When installing a plastic pipeline, you need to know exactly what pressure in the system they are designed for. If the plastic can withstand about 100 bar, then the copper pipe is 500 bar. This makes it possible to install additional equipment, for example, pumps for increasing the pressure in two- and three-story private houses.

Most often, copper pipes are produced with an admixture of zinc. The copper-zinc alloy is called brass. In addition to zinc, it contains 5 more elements. According to GOST, it is allowed to manufacture pipes for water supply from pure copper and brass.

Due to impurities, products last longer than plastic ones - up to 80 years, additives allow to restrain corrosion processes, affect strength. If a crack occurs in a copper pipe, it does not extend over its entire length, so leaks are easier and faster to repair.

Copper weighs 8920 kg / m3, which makes it the heaviest metal. For comparison, steel weighs 7800 kg / m3, polymers 900 kg / m3.

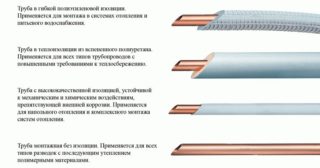

Copper can be used to create the thinnest pipes with the smallest difference between the outer and inner walls. There are two types of copper pipe production:

- with annealing;

- without annealing.

The result is hard, semi-rigid, and soft metal varieties. The installation of copper pipes for water supply also depends on how the product was manufactured.

Pipes are produced by rolling and pressing. The rolling method involves flaring the sleeve using a cold seamless method. Pressing is the welding of a copper sheet in an inert gas atmosphere followed by calibration.

Types of copper pipes

In the assortment of copper pipes there are about 130 types of items, which differ in shape, method of production, inner and outer diameters. Dimensions are in inches and millimeters.

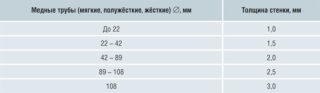

The dimensions depend on the manufacturing method. Round products have a diameter of 3 to 350 mm. The wall thickness can vary from 0.8 to 10 mm.

Welded products are smaller - from 30 to 280 mm. The wall thickness in welded and rectangular pipes can be greater - from 5 to 30 mm.

Copper sections with a diameter of up to 18 mm and a length of up to 10 m are on sale.A larger diameter is sold in sections from 1.5 to 6 m.

Dimensions of imported products may vary. The above dimensions are inherent in domestic products.

Advantages and disadvantages of copper plumbing

- Versatility of connections. You can save on fittings and couplings, since welding provides a reliable connection - during pressure testing, the pipe body almost always could not withstand, but the connections remained intact.

- The copper line does not deteriorate at low temperatures. The consequences of heating copper pipes are much less catastrophic than with a steel or plastic water supply.

- Copper is not destroyed by chlorine, which is always present in tap water. On the contrary, chlorine forms a protective layer on the inner wall, which prolongs the service life of the products.

- Under the influence of ultraviolet radiation, no visible changes occur on the copper surface, unlike plastic, which must be insulated.

- Colonies of microorganisms and pathogenic bacteria do not take root on the inner walls.

- The degree of roughness of the inner surface of copper pipes is lower than that of steel or plastic products, so organic substances do not have time to settle - the gap does not narrow during a long service time.

- You can buy copper products from any manufacturer - the quality will be the same. For example, there are many fakes among plastic products, which, as a result, have to be changed after a couple of years.

- Copper pipes have a higher corrosion resistance, so less material is used for manufacturing. Steel structures are forced to provide for a large wall thickness with the expectation that rust will gradually destroy the material.

- In copper lines, there is no need to service the joints, since they are more reliable than the pipes themselves. In non-welded steel structures, fittings are a major problem.

Disadvantages of copper plumbing:

- The cost is higher.

- Cannot be installed in systems where the water flow rate is higher than 2 m / s.

- There should be no sand and other solid particles in the water, as they rub off the inner layer of the wall. If it is too thin, it can cause erosion.

- More installation requirements so as not to reduce the warranty period.

Lead should not be used as solder in drinking water systems, as it causes poisoning of the body and serious consequences.

The pros and cons of a copper plumbing also depend on how well the installation is done.

Installation and connection methods

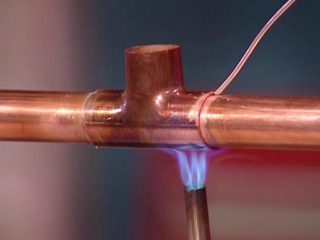

The most common method is soldering. To do this, it is necessary to heat the pipe to the melting point of the solder. Only experienced welders who often work with pressure systems and with complex communications in private and apartment buildings can solder copper pipes for water supply.

The process is carried out as follows:

- The junction of the pipe and fitting is cleaned of oxide film.

- A gas torch heats up the solder and gradually wraps around the product as it melts.

- In order for the solder to flow between the pipe and the fitting, the place is heated for a few more seconds.

Systems connected by welding are capable of withstanding pressures up to 500 bar, if properly carried out, leaks and depressurization of the line are excluded.

The pressing method is not very tight and reliable; it is better to use it in systems with low pressure. The bottom line is to assemble the system, and then a special tool is used to press the fitting to the main pipe. Clamping by means of a sealing band and a nut is possible. For control, it is necessary to make marks on the parts so that they do not budge during crimping. It is important to grind the pipe ends well before connecting to the fittings.

The advantage of the pressing method is that even a beginner can put it into practice. Solder welding is a much more complex operation requiring skill and eye.