The autonomous water supply system uses water from wells and wells. Its quality does not always meet safety standards. Organic and mineral substances are dissolved in it. Their high concentration can be harmful to health and leave scale on the surface of heating elements. Membrane technology for water purification is a modern and effective method. It is based on multi-stage filtration. The installation of the membrane ensures the purification of the liquid at the molecular level.

The device and principle of operation of membrane water filters

- the degree of contamination of the liquid;

- system pressure;

- water temperature;

- membrane area.

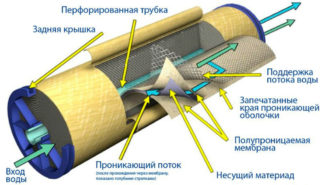

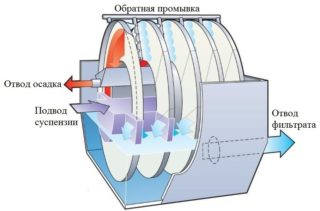

When passing through the filter, the water is divided into two streams. One is directed through the pores of the membrane. Passing through several layers of synthetic material, it is cleared of harmful impurities. The second stream is used to remove deposits.

The liquid that is free of contamination is called permeate. It is fed into the plumbing system. The water washing away the trapped impurities (concentrate) is sent to the sewer or used for household needs. The high level of purification allows drinking liquid to be consumed without boiling.

Types and design of membranes

- Microfiltration - hole size 0.1-1 microns. The material is used for pre-filtration, which separates fine suspended matter and colloidal impurities. The liquid becomes transparent.

- Ultrafiltration - parameters 0.1-0.02 microns, algae, microorganisms, metal oxides, small colloids are removed.

- Nanofiltration - pore diameter 0.02-0.001 microns. The filter is capable of removing heavy metals and chlorine compounds from water. The liquid comes out softened, the salt composition changes slightly.

- Reverse osmosis - the smallest openings in the membrane are 0.001-0.0001 microns. The material retains all impurities dissolved in water. Reverse osmosis systems remove bacteria, salts, pesticides, oil products. They are used in pharmacology, seawater desalination plants.

Membrane filters are classified according to the shape of the cleaning element.

Flat disc

- reinforced - a polymeric porous film is applied to a fabric base;

- substrate - the design provides for the use of an additional layer of material with large holes;

- unsupported - made of a homogeneous material (polyamide, nylon, fluoroplastic).

Disc diaphragm elements are the least in demand.

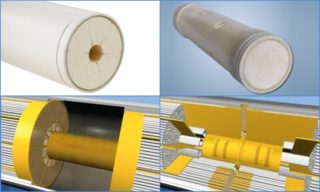

Roll

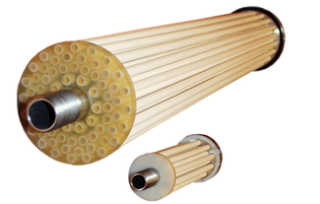

Tubular

Hollow fiber

Track membrane filters are offered for use in field conditions or in the country. The structure is immersed in a container with water, the purified liquid is removed by a drain tube.

Criterias of choice

Before buying a filtering structure, the water used is given for examination. The conclusion about its composition will tell you what type of membrane to install. High requirements for the quality of water treatment require the installation of a reverse osmosis system. When choosing a membrane, the pressure in the water supply network of the house is taken into account.

For the operation of an ultra- or nanofilter, 1-2 atmospheres are enough, reverse osmosis will require an increase in pressure to 3-3.5 atmospheres. The cost of a filtering structure directly depends on its capabilities. The most efficient system is expensive. The capacity of the installation is selected according to the average parameter of the family's water consumption.

Features of installation and operation

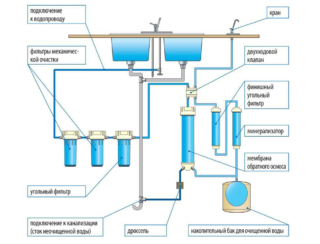

The membrane filter is installed on the cold water pipe. The rational installation option is under the kitchen sink. The device is located in the vicinity of a consumption tap and a drain. The installation procedure is indicated in the instructions. Before starting work, the movement of water in the system is shut off. Residues are discharged by opening the tap. The mixer outlet spins up.

A tee and a ball valve are installed on the line. A separate tap is installed at the sink for the flow of purified water. The filter unit is assembled according to the instructions. Before installing the reverse osmosis system, it is necessary to install several pre-treatment modules (mechanical, coal).

The membrane needs regular flushing. It is placed under the pressure of hot (40 °) water. In case of severe contamination, the block is immersed in a citric acid solution for 20-30 minutes. Then the part is thoroughly rinsed under a cool stream. The service life of the membrane module is 1-3 years, it is indicated by the manufacturer. A decrease in the fluid pressure and the appearance of a taste is a signal of the need for replacement.

Advantages and disadvantages

Advantages of membrane water filters:

- high degree of purification;

- convenient and simple operation;

- long term of use and the possibility of self-service;

- compact size.

Disadvantages:

- significant water consumption;

- high degree of removal of minerals from the liquid during reverse osmosis;

- the need to install an outlet into the sewer.

Membrane water treatment methods are used for domestic, medical and technical purposes. When installing the system in an apartment, it is necessary to periodically monitor the level of salt in the liquid using a TDS tester.