Reinforced-plastic pipes are widely used for heating systems and hot water supply. Due to their reliable technical characteristics, combining the strength of the metal and the elasticity of the polymer, communication elements serve regularly for up to 30 years or more. The main thing is to choose the right diameter of metal-plastic pipes for water supply / heating.

Design features of tubes made of metal-plastic

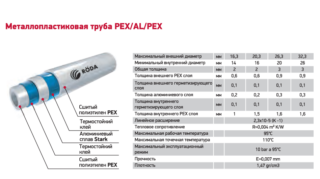

- inner polyethylene layer providing load-bearing function;

- a layer of aluminum foil on top - stabilizes the product and prevents oxygen diffusion;

- the outer polyethylene layer, which has a light shade, performs a decorative and protective function.

A special glue is laid between each layer of the metal-plastic pipe.

Specifications

- low level of thermal conductivity - 1300 times lower than that of copper, and 175 times less than steel;

- wall thickness from 2 mm or more, depending on the size of the metal-plastic water pipes (section);

- good antistatic properties - no conduction of stray currents;

- mass of a running meter of a product with a diameter of 16 mm. - 115 g.;

- throughput - 0.113 l / linear meter for a product with a section of 16 mm;

- transverse rupture strength - 2880 N;

- the coefficient of roughness of the inner walls - 0.07;

- expansion index of metal-plastic - 0.26x10-4 per ºС;

- the minimum permissible bending of the product is from 45 mm.

For all types of metal-plastic tubes, the strength of the adhesive bond of the aluminum layer is from 70 N / 10 mm2.

Types of metal-plastic pipes for water supply

All tubes made of metal-plastic are conventionally divided into two types according to the type of product composition:

- elements marked with PEX (cross-linked polyethylene);

- PE-RT pipes (heat-resistant polymer).

In turn, all PEX products with crosslinked molecular chains are additionally classified as follows:

- PEX-A. They have a maximum firmware step of 85%. Extremely durable and flexible.

- PEX-B. The degree of stitching is 65%. The layers are processed using silane. Pipes are less elastic, which means there are restrictions on the permissible bend.

- PEX-C. The main advantage of such a tube is its favorable cost. PEX-C products are ideal for straight sections without the need for bending material.

There are PEX-D tubes. Their production has been curtailed because the products cannot compete with more sophisticated models.

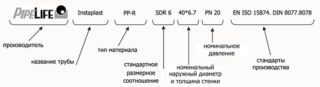

All tubes without exception are marked with special markings. It is prescribed in this order:

- manufacturer;

- certificate or GOST according to which the products are manufactured;

- type of material and method of stitching (PP-R, PE-R, PE-X);

- the diameter of the product plus the thickness of its wall (the section is indicated in mm, in rare cases in inches);

- nominal pressure in bar;

- type of transported medium (water pipes are not suitable for sending aggressive compounds through them);

- batch number and date of manufacture of the product.

All markings are applied to the tube in a continuous font.

How to choose

When buying products for plumbing or heating, the master should pay attention to the following parameters:

- the thickness of the reinforcing layer - the larger it is, the tougher and stronger the product;

- the purpose of the pipes is for water, heating, aggressive media that have a specific temperature during transportation;

- the type of stitching - the higher it is, the more elastic the tube will be for bending;

- manufacturer - the cost of production often depends on him.

It is advisable to take the items from specialized stores, in which the buyer is given a check. If necessary, it will be possible to return the product or exchange it.

Installation and connection

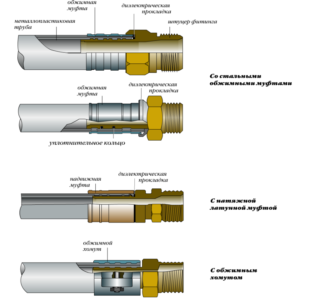

When installing a heating / water supply system, the master can join pipes in two ways:

- using press fittings;

- using a screw compression fitting.

Working with a press is done as follows:

- cut off the desired piece of the tube with special scissors;

- using a calibrator, an internal chamfer is cut from the prepared element (one end of it);

- the same is done from the outside of the pipe;

- the calibrator aligns possible crumpled places in the product lumen;

- drive the shank of the press fitting all the way;

- insert the sleeve into the press and bring its handles all the way.

This method of connecting tubes made of metal polymer is considered the most reliable.

If the technician uses a screw compression fitting, the two elements are joined in the following sequence:

- cut off the desired section of the product;

- remove internal and external chamfers;

- a compression ring and a tightening nut are mounted on the prepared end;

- the end of the second pipe is driven into the joining element;

- pull the ferrule and the tightening nut to the fitting until it stops so that it covers the ring; here it is important not to make critical efforts so as not to break the thread; the connection can be sealed with fum tape.

It is forbidden to embed pipe sections connected with fittings into the walls / floor. Only straight, unbreakable sections of communication can be removed into cement.

Advantages and disadvantages

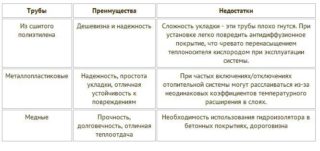

Important positive aspects of metal polymer products are:

- perfect smoothness of the inner walls, which prevents silting of the system;

- durability - the service life of a metal-polymer multilayer pipe for hot water supply is about 50 years;

- inertness to corrosion and aggressive media;

- good plasticity;

- light weight, which facilitates the transportation of products and their installation;

- easy installation of cold or hot water supply systems that does not require complex tools;

- soundproofing characteristics - the transportation of water through such systems is almost inaudible;

- aesthetics.

With their positive characteristics, metal-plastic pipes are not without drawbacks. The main disadvantage is the different coefficients of expansion of the polymer and the metal interlayer at temperature extremes. As a result, over time, the joints can weaken, leading to leaks.

Tubes are afraid of the sun, so they are used for laying internal communications in an apartment, a bathhouse, a country house. Sunlight provokes heating and further expansion of the tube. At the same time, cold water causes the polymer to shrink. Temperature changes are undesirable for such a material.

The price of pipes made of metal-plastic

The cost of products varies depending on the manufacturer and the diameter. Average prices for pipes for water supply from metal-plastic in Moscow:

| Manufacturer | Country | Price m / running ($) |

| Valtec | Russia, Italy | from 1.5 |

| Oventrop | Germany | from 1.2 |

| Henko | Belgium | from 0.8 |

| Nanoplast | Russia | from 0.7 |

| Comap | France | from 1.6 |

Prices are given for pipes with a diameter of 16 mm. The larger the cross-section of the product, the higher its cost per running meter. In addition, prices may vary slightly depending on the region of sale.