The construction of external water pipelines provides private houses or summer cottages with drinking water. The quality of the installation of the water main will determine not only the efficiency, but also the duration of operation, the complexity of the repair and preventive work.

Requirements for the arrangement of external water supply and sewerage networks

The internal piping is always connected to the external water supply network. To supply fluid to the required object, special pumping equipment and pipes are used. Installation work is carried out in accordance with SNiP regulations. An important point - when laying the pipeline network, the depth of soil freezing is taken into account.

When installing an outdoor system, other requirements are also taken into account:

- Project work. Drawing up a project and drawings, obtaining permission to perform these works.

- Availability of the required documentation from technical supervision.

- Monitoring the quality of hidden work.

- The use of high-quality consumable tools and materials.

When equipping an external water supply and sewerage system, you need to correctly install the network. Damage, violation of the integrity of other communications that have already been laid on this site is unacceptable.

The types of outdoor networks are divided into two large groups:

- A local network is necessary to provide water to certain objects, it is designed in the absence of a centralized highway.

- The centralized network provides water to entire settlements, cities, etc.

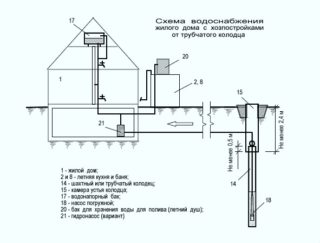

The source of water for local networks is a well. Therefore, in addition, to raise water to the surface, it will be necessary to install a surface or submersible pump.

Material of pipes for external water supply and sewerage

Installation of an external water supply system from polyethylene pipes is most common today, due to the large number of advantages of the material and the following list of characteristics:

- The size of the outer diameter of the pipe is from 25 mm.

- Operating temperature - up to 40 degrees (low pressure polyethylene pipeline is intended only for cold water).

- The melting point of the substance is about 125 degrees.

- High plasticity rates of pipes allow to endure freezing with water inside, without deformation, tears, etc.

- The material is resistant to corrosion, no deposits form, therefore, the throughput does not decrease. The service life of polyethylene pipes reaches 50 years and more.

- Easy to assemble with crimp fittings. It is important that the fittings are in easily accessible places in case of breakdowns, otherwise the pipeline must be welded.

- They can be supplied as separate straight pipes up to 12 meters long or in coils over 50 meters long.

Another advantage is that the material can be supplied up to 1 km long in bays. Indeed, one of the main features of an external water supply system is the absence of a large number of joints along its entire length. Threaded connections are prohibited.

Using a special welding machine, it is possible to weld individual parts of HDPE pipes.

When installing an external pipeline in a trench, care must be taken to ensure that the pipe lies solid.If this cannot be achieved, you need to connect the parts with fittings or weld, and also equip a manhole, which will allow, after repair, if necessary, to monitor the condition of the connections.

Preparatory work and installation stages

- pumping station;

- locking mechanism;

- storage tank, which is needed to maintain optimal pressure parameters;

- devices regulating the process of water supply;

- pipeline.

All work must be regulated by regulations SNiP 2.4.2-84, SNiP 3.5.4-85 *. May be:

- ground-based: on supports and overpasses with subsequent insulation or its absence;

- underground: characterized by trenching.

For the installation of an external water supply system at a summer cottage, it is more advisable to give preference to the latter option. For implementation, special equipment and equipment may be required, but if the area is small, you can dig them out yourself.

The stages of installing an external water supply system include the following processes:

- Soil preparation and digging of trenches (pipe depth not less than 0.5 m).

- Pipe laying and connection.

- If necessary, insulation of the elements of the water main.

- Sealing up the place where the pipeline enters the house.

In conclusion, be sure to check the system for leaks.

Excavation works

- On the personal plot, the approximate location of the pipeline network is outlined and, according to the size, land is excavated, the depth of the trench depends on the approximate depth of soil freezing. As a rule, it fluctuates between 1.5-1.8 meters. The value of this parameter is also influenced by the duration of low temperatures in the region, soil density and its moisture content. The optimum trench width is 50 cm.

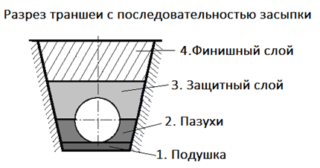

- The bottom of the trench must be leveled. If the soil is loose, it is additionally rammed. Before laying the pipes, equip a pillow made of gravel or sand.

- Pipes are placed on the prepared pillow; pits must be made at the joints.

After laying and compaction, the pipeline is covered with sand or gravel by 10-15 cm, then the withdrawn soil is used.

Flange mounting technology

Flanged joints are used to connect plastic or polyethylene pipes with a diameter of more than 63 cm. This is due to the undesirability of using a welding machine. Flanges are easy to use and install, there is a wide range of standard sizes. The connection procedure is as follows:

- Using a pipe cutter or scissors, the edges of the pipes are cut at right angles (90 degrees) according to the previously applied markings.

- Work surfaces are cleaned of dirt, for this they use liquid soap or an industrial composition for cleaning floors.

- The union nut of the fitting is unscrewed by 3-4 turns, then the pipe is inserted into it to the applied mark and the nut is tightened.

When joining parts, it is important to pay attention to the applied force. The joints must be sealed.

The price per meter of work on the laying of external water supply and sewerage networks varies significantly depending on the region. For example, the initial cost of a trenchless laying is 2,500 rubles, and of a trench from 500 rubles per meter.