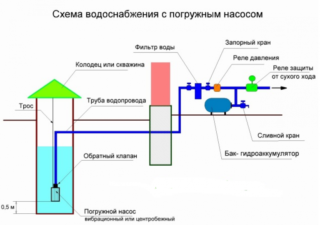

Away from centralized water supply networks, the well becomes the main source of water. To supply it to the house, a pipeline is equipped. In order for the liquid to move through the pipes, it is necessary to install a submersible pump in a well. The equipment creates a pressure that raises the water to the desired height. Simultaneously with the installation of the unit, communications are laid from the source to the house.

Features of installing a submersible pump in a well

The reliable operation of the water supply system is ensured by a pump with optimal characteristics. When choosing a unit, take into account its power, head height, ability to function in water with pollution. Responsible buyers value additional qualities. Models with built-in dry-running protection will not fail if the water level drops sharply.

For wells, two types of submersible pumps are recommended: vibrating and centrifugal. Vibrating units have low performance, but are affordable. Centrifugal mechanisms will provide the house with the right amount of water. Models of well-known companies are distinguished by long-term operation.

Installation of a borehole pump in a well is carried out in two positions:

- Vertical - The position is suitable for any shaft size. The equipment is mounted on one cable.

- Horizontal - location is possible for models with an engine cooling jacket. Manufacturers make eyelets to secure the cable in two places.

One of the installation rules is that there should be a distance of 1 m from the bottom of the well to the unit.

Required tools and materials

When making a water supply plan, the length of the pipes is calculated and the material of the line is selected. A common option is PVC or propylene products. Plastic pipes do not rust, no plaque builds up on the walls. To prevent freezing of the line, a casing-insulation made of foamed polystyrene or polyethylene is used. You will need consumables for the installation of the pipeline:

- couplings;

- tee;

- fitting;

- ball valve.

To suspend the pump, a steel frame is required. Metal corners are prepared for her. The cable holding the unit must be made of stainless steel or nylon.

Tools for the job:

- shovel;

- puncher;

- grinder or hacksaw;

- roulette;

- pipe cutter.

Installation of equipment is best done with a partner. He will help to dig a trench, hedge when lowering the unit into the well.

Installation steps

Pipeline laying

- The smallest distance from the house to the well is chosen. The number of bends on the track is taken into account.

- A trench is dug up to a depth of 1.5 m, a width of 0.5 m. A 20 cm layer of sand is poured at the bottom. The pipes are connected by fittings into a common line, and a heat-insulating casing is put on top.

- A hole is made in the concrete ring of the well shaft and a sleeve is inserted. The cracks around it are sealed with cement mortar and bitumen. Through the sleeve, the pipeline will be connected to the pump. A tee is installed at the end of the pipe. One of the outputs is diverted under the tap.

The length of the sleeve at the entrance to the shaft is 40-50 cm. The diameter of the pipes must match the size of the outlet.

Preparing the pump for submersion

The preparation of the unit is carried out on the surface. The distance is measured from the point of connection of the pipeline to the outlet of the pump. The pipe or flexible hose is cut to the required length. A check valve must be located immediately behind the unit, if it is not in the structure, the part is installed by the installer. The pump is laid on a flat area, the end of the pipe is placed near the outlet. A coupling is required to connect them. The connection is sealed with fum tape.

The electrical cable is straightened and laid along the pipe. Plastic clamps are recommended to secure the structure. They are put on every 50 cm. The wire should not be taut, a slight sagging is desirable. The power cable is led to the shield through the finished ditch of the water main. To protect the wire from mechanical damage, it is placed in a plastic pipe.

There is an eyelet on the body of the unit for securing the safety cable. Do not use a power cable for hanging. The submersible pump is ready to be lowered into the shaft.

Submersion of the unit into a well

To properly install the pump in a well for supplying water in a house, you will need a strong welded frame made of metal corners with a channel in the middle. It is made according to the size of the head. The structure is attached to the upper ring of the shaft. The equipment cable is attached to the frame. The pump is lowered carefully, without swinging. Depending on the weight of the product, you can do the job together or use a winch. It remains to connect the unit to the pipeline. To do this, you have to go down the stairs to the well. The worker must be secured with a rope.

Automation

The unit is connected directly to the electrical network in case of infrequent use. With continuous operation of the equipment, the installation of automation is necessary. The simplest option is a hydraulic accumulator with a pressure switch.

The second generation automation does not require a tank to be included in the system. It reacts to the pressure in the pipes.

Third generation instruments monitor the pump motor speed. Electronic blocks ensure a stable pressure in the water supply network.

How to avoid common mistakes

When connecting a submersible pump in a well, beginners make mistakes. Some shortcomings can lead to interruptions in the operation of the equipment or its failure. Common problems include:

- Using a metal cable. Over time, the steel becomes covered with rust, the strength of the safety cable is lost. A thick nylon cord is preferable.

- Insufficient cross-sectional area of the electrical cable. The parameters of the wire for connection to the network are specified by the manufacturer. You can not take a cable with a smaller section. It will overheat, equipment interruptions will begin.

- No check valve in the system. Most models are equipped with this part, but budget products require self-assembly of the valve. Without installing it, water will drain from the pipes after each shutdown of the engine of the unit.

- Low pump location. If the intake hole is close to the bottom, sand and silt particles will get into it. The filter gets dirty quickly.

- Installation of the unit near the shaft wall. Equipment may be subject to impacts if the housing is close to the sump ring. It is located in the central part of the mine. In case of unavoidable contact, the housing is protected with a rubber ring.

Simultaneously with the installation of the pump, it is recommended to include a hydraulic accumulator and an automatic relay in the system. A sealed tank is used to create and maintain pressure in the water supply system. The relay controls the turning on and off of the equipment. The use of automation reduces the number of work cycles. The life of the pump motor is extended. The system is protected from surges in water pressure and water hammer.