When building a water supply system for a private house or summer cottage, it is necessary to take into account many nuances: a well and pumping equipment, pipes and control systems, water purification. If there is no experience in such work, it is better to entrust everything to construction companies or invite a consultant who will help you choose materials, equipment, tools, draw up a project for a water supply system and give valuable instructions on the stages of installation.

Water supply of a private house or summer cottage

It is impossible to imagine life in a country house without water supply. The presence of a well or well does not mean a comfortable existence, because water will have to be carried in buckets, and household appliances will not be able to work. It is difficult for elderly people to cope with washing, washing dishes, cleaning without a stationary water supply system.

First, you need to select materials and calculate the water consumption per day in order to buy a pump of suitable power. Next, you need a water supply scheme at the site, which will deliver the liquid to the house by the shortest route. If there is not even a well near the house, the volume of construction work increases, since a well will have to be drilled.

It is advisable to lay a sewage system parallel to the water supply and install a septic tank to drain the waste. This can be done at the same time - when building a house, these works are combined to save time and money.

Types of water supply systems and their device

- Branched. In this case, the liquid moves along the main highway and is directed to dead-end areas - to houses.

- Annular. It is assumed that all sections are interconnected.

- Combined. This is a complex of dead-end sections of the system and the ring highway. The most common type.

A branched system is used to supply water to a private house: liquid from its own well enters the house, garage and other household buildings - dead-end areas. This system is also called autonomous. Several sections can be connected to it. In this case, the source must have large reserves and be quickly updated. Artesian wells have these characteristics, but require high drilling costs. It is profitable to build them with the joint financial efforts of the tenants.

For the city, ring and combined schemes are more often used so that one section does not suffer if the other is turned off.

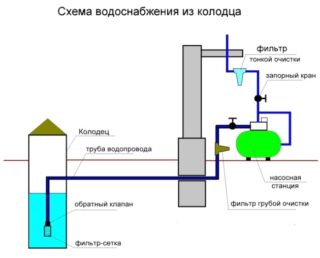

The general scheme of the water supply system consists of sequentially connected sections:

- A source.

- Pump.

- Pipeline.

- Hydroaccumulator.

- Faucet in the house.

The main elements are the pump and the accumulator, since they produce and maintain pressure in the system, without which the liquid cannot rise to the surface and enter the house.

Installation requirements

The installation of water supply and sewerage systems must be carried out together with general construction work. It must be completed before starting the finishing work. This reduces costs, since ditches are immediately made for water and sewer pipes, and a well and a septic tank are being dug. In this case, it is easier to comply with sanitary standards for the placement of dirty drains and clean water.

The inner pipes can be wrapped with soundproofing materials while the walls are under construction, so as not to return to this problem later. The same applies to the insulation of sewer and water pipes.

The slope of the pipes is important when arranging a gravity sewer. In the case of water pipes, you need to correctly calculate the length of the line from the well to the house, take into account the height of the rise of water from the source.

During the construction of a water supply system, it is necessary to include viewing wells in the scheme, the same applies to sewer pipes.

Design

Plumbing systems are designed by licensed companies. Only in this case it will meet all standards - sanitary, technical. The plus is that firms give a guarantee for their work and issue the relevant documents. In the event of any unforeseen breakdowns, according to the documentation, it is possible to assume the most vulnerable point. The diagram of the highway and its components will always be at hand - in case of installation on the site of any other buildings.

Design includes:

- layout of household and plumbing devices in the house;

- determination of all points of water intake;

- accounting for all piping and placement of pipes inside and outside the house.

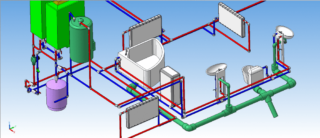

Hydraulic calculation is the determination of the required pressure and power of the pumping equipment so that the water pressure is sufficient for all points of water intake.

Cold and hot water supply systems are designed at the same time, so that after finishing work, you do not encounter errors, for example, the proximity of the pipes of the hot and cold circuits.

During the design process, the amount of basic and additional materials is calculated.

Tools and materials for water supply

A pipe cutter for plastic will definitely come in handy, since most private owners choose polymer products for arranging a plumbing system, both internal and external. To work with metal-plastic pipes, you need to have a pipe bender that gently bends the plastic and does not create creases. A set of wrenches for installing shut-off valves and other parts.

For outdoor work, shovels may be needed, even if an excavator will be drilling and digging a hole under a well or septic tank. To measure the depth, you need a rope with a weight or a long tape measure. When laying sewer pipes, a building level will be needed to measure the slope.

At the same time, in the supermarket, it is necessary to select materials for isolating the sound coming from the water supply and insulating pipes. It can be any kind of mineral wool - soft or rock - hard materials are suitable for laying in the soil.

Pump selection

After all the calculations, you can immediately buy pumping equipment of the required capacity. The choice in stores is large, but it is important for which source it is intended. For wells - some models, for wells - others.

- Centrifugal type. They are more expensive, but have a good head and are able to get liquid from a depth of up to 300 meters. The submersible pump body is made of stainless steel, cast iron or brass, therefore it can withstand constant exposure to liquid.

- Vibrating. These units are more suitable for wells, as they do not create waves and do not silt the bottom.

- Vortex ones are similar in principle to centrifugal ones, but they have a higher head.

- Pumping stations - the depth is limited to 8 meters, but the units are equipped with a hydraulic accumulator that maintains pressure.

Pump selection criteria are primarily power and head. If the source is far from the house, the head height should take into account the horizontal line, as well as the height of the house and the depth of the well itself.

The performance of the equipment should not exceed the flow rate of the well, so that dry-running sensors do not work if the pump pumps out all the liquid.

The presence of degrees of protection is taken into account.This will help preserve the engine if the sump liquid level drops.

Pipes

Most residents opt for polymers - polypropylene, polyethylene, PVC and metal-plastic. Few people prefer metal, cast iron, since the installation of heavy pipes requires the involvement of labor and technology. You will need a professional welding machine and skilled workers to connect pipe sections.

There are many grades of polypropylene and polyethylene that are suitable for cold and hot water piping and also withstand cold temperatures in winter. When buying, you need to know exactly what the materials are for and in what conditions they will be located. Technical characteristics of pipes can be checked with the manager.

If you butt-join plastic products, you may need a welder. It is leased by construction companies, since the device is expensive. The construction of a water supply system from polypropylene pipes with your own hands is much cheaper both in terms of the cost of the material and the effort expended.

Installation sequence

It is better to drill a well on sand or limestone, since the upper waters are extremely unstable in the amount of liquid in summer. For casing, plastic or double pipes are used so that the mine does not get dirty from rust and withstands the pressure of the soil.

This is followed by laying pipes and connecting the sections to each other. This is done by a welded or coupling method. Using fittings, the connection is sealed with tow and resin. Polymers can shrink and expand when exposed to temperatures, causing leaks. It will be difficult to eliminate them in the ground.

The sewer line is laid according to the scheme, observing the slope. If it is not provided, a pump is needed so that the sewage flows into the septic tank and does not stagnate in the pipe. Inspection wells are installed at turning sections and forks, since this is where accidents most often occur.

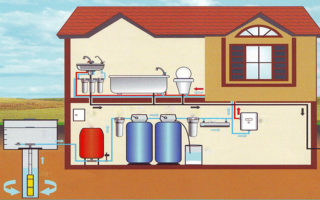

At the same time, the following works are being carried out in the house:

- installation of pipes and their connection to household appliances;

- installation of a boiler or other heating devices;

- installation of metal-plastic pipes for water supply systems and underfloor heating, after which the wiring is poured with concrete.

The last step is to connect the pump. If it is not equipped with a hydraulic accumulator, you will have to do it yourself. You need to buy a hydraulic tank of a suitable volume, a pressure switch, a pressure gauge and connect the tank to the inlet pipe. If the factory settings are not suitable, they should be changed by tightening the lower and upper springs in the pressure sensor.

After connecting all the nodes, testing is carried out, but until the trenches are covered with earth. If the equipment is working properly, there are no leaks, you can fill the line with soil.

Prices for the installation of water supply depend on the amount of building materials, their quality. Pumping equipment, depending on the choice of the manufacturer's brand and technical characteristics, can also be expensive. If you order all the work in specialized firms, you can save money, since they buy materials and equipment in bulk.