To connect PVC, PET or polypropylene pipes, plumbers use plastic plumbing couplings. Similar elements are also made of metal. The type of fitting is selected depending on the situation, based on the specific technical parameters of the pipeline.

Definition and purpose of the water sleeve

A coupling is a special fitting designed to tightly connect two pipeline elements. The inner section corresponds to the outer diameter of the tubes to be connected. It is important to select a fitting from the same material as the communication pipes.

Mostly, couplings are used when installing various engineering networks or when installing a pump on them. Fittings are widely used in the following areas:

- installation of water, gas, oil pipelines;

- building sector;

- all types of industries: pharmaceutical, chemical, food, metallurgy, etc.

In private construction, plastic repair couplings are mainly used for a water pipe. All fittings are manufactured strictly in accordance with GOST, since they are subject to increased requirements for strength and tightness.

Fittings types

All couplings are divided into groups according to the material of manufacture and the method of installation. In the first case, the following elements are distinguished:

- metal: steel, cast iron, brass, bronze;

- polymer: metal-plastic, PVC, PVC-U, polypropylene, low-pressure polyethylene.

Without exception, all fittings are in the form of a short pipe, which is put on over the main parts of engineering communications. Two opposite pipe sections are inserted into the fitting until it stops. The clamped sleeve fixes them securely.

The elements are divided into groups according to the method of installation:

- Threaded. They have an internal thread at both ends. Connect the fitting to the pipe using the screwing method. Such elements are more often used for a metal pipeline.

- Crimp. Mainly applicable for PVC plumbing.

- Welded. Installed by special welding (soldering). They are more often used when laying underground PET networks (polyethylene communications).

- Compression. They are mounted without the use of special equipment.

There are also special push-couplings on the market, which are mounted within 1-2 seconds. Simply connect the pipe by pushing it into the fitting until it clicks.

The main criteria for choosing water couplings

Before buying a connecting element, it is important to consider the following parameters:

- Diameter. The inner section of the coupling must fully correspond to the outer diameter of the pipe. Otherwise, the fitting will either not slide over it, or it will dangle. In neither case, the tightness of the network is out of the question.

- Coupling length. This parameter is especially important when installing a pipeline in a limited area. The fitting may simply not fit into the allotted niche.

- Manufacturing material. It is important to select the coupling exactly from the same from which the pipes are made. This ensures optimal compliance of the engineering network with the declared characteristics of the material.

- Intended use of a specific section of the pipeline. If it is supposed to carry out additional repair work or install branches, then it is rational to mount a threaded (collapsible) coupling. It can be removed later.

If in doubt about the correctness of the choice, a consultant at the point of sale will always help.It is only important to know the basic parameters of your water supply system - the material for the manufacture of pipes and their diameter.

Coupling installation principles depending on the type of connection

Each type of fitting has its own installation technique. It is important to observe it strictly, otherwise the tightness of the pipeline will suffer.

Threaded couplings are installed as follows:

- The water in the riser is shut off to avoid an emergency.

- The pipe is cut at the intended place strictly perpendicular to its axis. If we neglect this, the ends of the tube may not converge later in the sleeve.

- A thread is cut for each part of the disassembled pipe.

- Then the master puts on the clamping nuts on both sides. With their help, the connection will be tighter.

- Both ends of the pipe are screwed into the coupling from both sides.

- The last step is clamping the nuts. They must be firmly pressed against the walls of the coupling.

Welding is used when installing PP fitting. The coupling for connecting polypropylene water supply pipes is installed as follows:

- The pipe is cut in half at the intended location.

- The edges are deburred inside and out.

- A special soldering iron with nozzles is heated to the desired temperature.

- The wizard inserts the coupling and the pipe section into their corresponding connectors. Here, the polymer softens when exposed to high temperatures.

- After 10-12 seconds, you can insert a piece of tube into the sleeve and drive it in until it stops.

- The cooled polypropylene forms a tight, durable connection.

Bonding is used when installing PVC fittings. In contrast to the effect on the polymer of high temperatures, special glue is used here. Its aggressive composition somewhat softens polyvinyl chloride, resulting in adhesion of the material. The works are performed in the following sequence:

- The water pipe is cut at the intended place.

- One end of it is inserted into the sleeve and the place of the stop is marked with a pencil.

- The segment is taken out and coated with special glue along its surface to the intended line.

- The prepared pipe is inserted into the fitting and turned a quarter turn for good distribution of the adhesive.

- Already after 1-3 minutes, the second piece of PVC pipe can be connected in a similar way to the coupling.

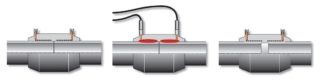

Electric welding: use special HDPE fittings with built-in spirals. The installation process looks like this:

- A clutch is put on the prepared parts of the network.

- An apparatus is connected to the fitting, which is powered by electricity and supplies it to the spirals.

- As a result of this effect, the latter heats up and melts HDPE. The elements of the pipeline are being welded.

Installation of the compression sleeve is carried out in the following sequence:

- Prepare the two ends of the tube, cleaning them from dirt and burrs.

- All elements of the compression fitting are put on the pipe: collet ring, nut, etc.

- The prepared section of the water supply system is inserted into the coupling branch pipe or put on the fitting.

- The collet ring moves in and the nut tightens.

It is not recommended to tighten the nuts to the limit, especially on polymer pipelines. Excessive force can crack the system.

Crimp: The technician prepares two ends of the pipe and inserts them into the fitting. The junction of the sleeve is crimped with a special device. It ensures the tightness of the coupling with the pipe.

Whichever type of plumbing fitting is chosen, it is important to connect all the parts without haste and consistently. The strength of the connection and the tightness of the system as a whole depend on this. Violation of the installation technology can provoke an emergency in the riser.