Plumbing installation requires the assembly of individual elements into a single system. Metal pipes and valves are joined by a threaded joint. The method provides a strong and sealed bond. For self-laying communications, you will need tools for cutting threads on water pipes.

Types of threads on pipes

A thread is an alternation of protrusions and depressions on a surface, located along a helical line. It can be external and internal, left and right. Common types:

- tubular cylindrical;

- pipe conical;

- inch cylindrical (US standard);

- round;

- inch.

In the installation of plumbing works, the first two types are usually used. They are used to connect plumbing fittings:

- Cylindrical (G) - The profile is represented by an isosceles triangle with an apex of 55 °. The protrusions and depressions are rounded. Recommended for pipes up to 6 ”diameter.

- Tapered (R) - the thread has a triangular profile, forms a taper of 1:16, is characterized by high tightness of the connection of parts.

Pipe threads are either inch or metric, respectively, measured in inches and millimeters.

Required tools

- A die or punch - a device in the form of a hardened metal nut, has sharpened cutting edges (cutters). They are round, square, hexagonal in shape. Types of dies: solid, sliding, split. Holes are provided for the removal of chips.

- Klupp is a tool based on a sliding die. The two-piece body allows you to adjust the cutting diameter. For the convenience of work, a handle is arranged. Some models are equipped with a ratchet that allows rotating movements with one hand. The professional tool is equipped with an electric drive.

- The tap is a hardened steel screw with cutting edges. Consists of a working part and a shank. The set includes devices for roughing and finishing work.

Additionally, auxiliary devices are prepared:

- tape measure and pencil - for measurements and marks;

- vernier caliper - determines the diameter of pipes and fittings.

The tools used must be of high quality, the metal of the cutters is sharp and durable. When working with dies and taps, a vise is needed.

Preparation for work

The area where you will have to work with a threading device for water pipes is cleaned of rust, dirt, paint residues. Sandpaper is used. The surface should be cleaned to a metallic sheen. The end surface is chamfered. Prepare pipe and cutting tool lubricant. A rag is required to clean the shavings.

Water pipe threading methods

Dice cutting

The choice of the type of tool depends on the quality requirements.The best result is achieved when using a solid die, which has high rigidity. The disadvantage of the device is rapid wear and tear. Spring-loaded dies (with a cut in one of the axial holes) allow you to change the thread diameter within 0.3 mm. Their rigidity is reduced, the incisors last longer, but the purity of the threads is lost.

The prepared pipe is clamped in a vice. The die is placed in the holder and fixed with screws. Grease is applied to the area to be treated and the cutters. The tool is put on the pipe at right angles. The rotation is smooth, clockwise. After several turns have been made, the chips are removed and lubrication resumed. For high-quality cutting, after the rough cut, a finishing one is used. The finished thread is cleaned with a rag.

Using klupp

The use of a pipe die is more convenient than dies. The tool is more expensive, but for a large amount of work, it is better to choose it. Klupp gives a clean thread, the sliding design allows you to adjust the thread diameter. The installation of guides reduces the risk of distortions, facilitates the cutting process. If a ratchet is included in the structure, a ratchet wheel is placed near the die. When turning it, the tool head moves. The ratchet is indispensable in cramped working conditions.

The pipe is clamped in a vice, leaving a small area. The short protruding part will not allow the metal to bend from the applied force. The pipe and cutters are lubricated with machine oil. The protruding part is inserted into the die guide. Slicing takes place with short rotational movements. Rotate backward periodically to cut the chips. Grease is added during operation. When threading water pipes, it is important to keep track of the number of threads.

Using an electric tool allows you to cut in a few seconds. Replaceable heads with cutters are selected for the required pipe diameter. The work is not only fast, but also of high quality.

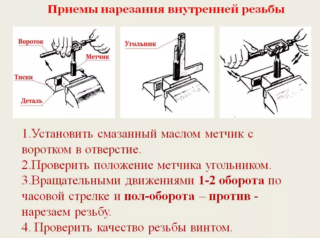

Tap work

- one is black;

- two - middle;

- three - finishing.

The inside of the pipe needs to be cleaned and lubricated. The tap is inserted vertically, the shank is fixed in the tap. The rotation is clockwise. When working with soft metal, the tool is periodically turned inside out and the chips are cleaned. Grease is required. After the end of the work, the quality of the thread is checked.

The main reasons for marriage

The reason for the defect in work is the carelessness of the worker or the use of a poor-quality tool. Common pipe cutting defects when working with a tap or die:

- Ragged threads - the problem arises when using a dull die, untimely removal of chips, insufficient lubrication.

- Incomplete Thread - The thread is larger than recommended.

- Misaligned helical grooves - improper die or tap installation.

- Breakage of the thread is the reason for the clogging of the grooves with chips, poor quality of the tool, the pipe diameter is larger than stipulated.

- Tap breakage - Excessive force applied to a narrow hole, insufficient chip removal, lack of lubrication.

Self-preparation of parts for a threaded connection is quite accessible with a tool. In order for the work to be done efficiently, you must follow the rules. The use of a sharp tool and accuracy make up for the lack of professional skills.