When buying or building a private one, the problem of water supply always comes to the fore. It can be a well or a well, from which it is necessary to organize the delivery of water to the house. This can be done using a pump and pipes.

Benefits of submersible well pumps

Pumping equipment is selected depending on the depth of the source. Surface pumps and stations are not capable of pumping liquid from depths below 8 meters. Next, you need to install an ejector, which will be very expensive. It is much more profitable to purchase submersible equipment, especially since there are several varieties on sale - you can choose by price, design, manufacturer's brand and technical characteristics.

The well is most often located at some distance from the house - in the garden, garden. This is another advantage in favor of a submersible pump, since the horizontal section of the path also requires power: 1 meter of vertical liquid lifting equals 10 meters of horizontal transportation.

When using submersible equipment, you do not have to equip a caisson for a pumping station, and this is an additional cost. The pipe simply connects to the outlet of the unit and stretches into the room where the accumulator is located, and then into the house.

The submersible pump housing is completely buried in the liquid, so the noise of the operating equipment will not be annoying. Cold water in the well prevents the device from overheating, which increases its service life.

For a well, you can choose any model, even a vibrational one, since a wide area of internal space reduces outgoing waves and the bottom does not silt up, as is the case with a well.

Since not all wells reach the sandy horizon, many of them are fed by the upper water, it is necessary to constantly monitor the liquid level. For this purpose, submersible units have automatic sensors that turn off the pump if the liquid level is below a critical one.

Surface or submersible equipment is used for installation in wells or wells. With its help, you can organize the watering of the summer cottage or the delivery of water to the house for domestic needs. For installation in a well, a drainage pump can also be used. It is less sensitive to dirty water and can only be used for watering.

Types of models, device

If the depth of the source does not exceed 6 - 7 meters and it is located not far from the water intake point, a pumping station equipped with a hydraulic accumulator is quite suitable. For work, it remains to connect the outlet to the supply pipe and lower the hose into the water. For the pumping station, it is necessary to equip a warm room - a shed, basement or caisson.

If you install a surface pump, you will need to buy a hydraulic accumulator for it in order to reduce the frequency of turning on the device. It is the frequent alarms that lead to breakdown. The pump housing is located on the ground, so the noise level rises sharply.

Varieties of submersible pumps for a well

A submersible centrifugal pump for a well is the optimal solution if the distance to the water surface exceeds 8 meters.It should be borne in mind that in sand wells and wells, the liquid level in the summer can drop significantly and you need to be prepared for the fact that you will have to lower the pipe below so that water flows into the house.

Centrifugal pumps are the most powerful and efficient. They have certain disadvantages, but insignificant ones:

- if the water in the well contains sand or stones, the impeller may wear off and then the performance decreases;

- the high cost of high-quality units, since the internal parts are made of durable materials that can withstand friction for a long time.

Vibratory pumps are less powerful, in addition, limited by the distance to the water surface. They are more suitable for wells than for wells, since the excitement that is created in the water due to vibrations does not significantly affect the rate of siltation of the source. Among the disadvantages is a short service life. The advantage is that they do not affect the process of destruction of the walls of the well, since they are located far from them.

Vortex pumps, in which the principle of operation is similar to centrifugal pumps, have a higher performance due to the presence of grooves on the walls. They speed up the movement of the fluid. The vortex pump device is simple, so it costs less. The service life is shorter than that of centrifugal models. Also, the equipment is sensitive to particulate matter.

Screw models can be considered, but they are rarely found on the market. They create a strong head, which can be an important parameter if the well is located far from the house. The units pump dirty liquid well and the internal parts do not break at the same time. Frequent maintenance may be required due to the large amount of rubbing elements inside the housing. The efficiency of such pumps is much lower than that of centrifugal pumps.

Principle of operation

The principle of operation of any pump without a hydraulic accumulator is to turn on every time water is used in the house. This leads to rapid wear of the electric motor, since the main load falls precisely at the moment of switching on. This principle can only be useful if you need a uniform flow of fluid over a long time, for example, when watering.

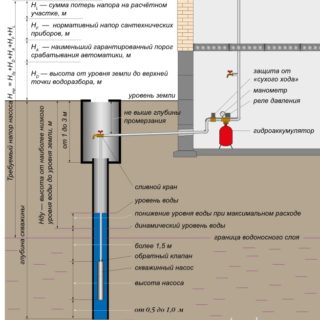

In other cases, it is necessary to install a hydraulic accumulator that accumulates a supply of water. The pump runs less frequently and therefore runs longer. The principle of operation of the accumulator is to maintain certain pressure limits. This is done using a relay and a pressure gauge. If the pressure in the system drops below the set level, the equipment starts up and pumps fluid into the container. It turns off when the gauge needle reaches the upper peak value. Then you can use the tap several times until the pressure drops again.

The upper pressure should not be higher than the parameter that is provided for household appliances, for example, a washing machine.

Criterias of choice

When choosing a device, pay attention to the following criteria:

- Electric motor power and technical characteristics. You may need to buy a voltage regulator separately to keep the motor running stably. It is better if a separate branch in the electrical network is allocated for the pump.

- The head of the water column is an important point if the pipe line runs horizontally underground. Calculate this parameter by the formula, adding the horizontal lifting height and the vertical length of the line, divided by 10. Plus, the water pressure in the house should be about 2 bar.

- The amount of liquid that the pump can pump over a unit of time. The flow rate of the well plays a role here, since the productivity of the equipment cannot be higher than the amount of liquid that the source can give at the same time.

- The dimensions of the body do not matter, this indicator is important for the well.It is better to choose a model with a lower water intake, in which case the water can be pumped out even at a very low water level.

- The contamination level of the liquid at the source.

- Availability of protection sensors.

- Materials for the manufacture of the body and internal parts.

- The length of the electrical cable, depending on the location of the well and the outlet.

- Noise level.

The manufacturer's brand can also influence the choice. There are firms that have proven themselves in the pumping equipment market. Buying such a device, you can count on long-term trouble-free operation.

Installation and connection

Features of operation and maintenance

During operation, it is necessary to monitor how often the surface or submersible pump is turned on. If the frequency has increased, and the liquid flows unevenly, intermittently or with air, it is necessary to check the integrity of the membrane in the GA. If necessary, replace it with a new one.

The absence of an overheat or dry run sensor can cause the equipment to operate outside the liquid and burn. In this situation, you need to prepare to buy a new pump or make expensive engine repairs.

1-2 times a year it is necessary to lift the submersible unit to the surface, inspect it for silting. It often happens that the housing becomes clogged with fine sand fractions and needs to be cleaned.

If you regularly service the device, its performance will be durable and stable.

Prices for well pumps with automation for water supply at home are higher than equipment without sensors. Such additional costs fully pay for themselves - residents may not always notice a decrease in the water level in the source, for them it will be done by automation. If the pump stops turning on, you will have to find out the reason and lower the unit lower into the water column so that the sensor stops responding to danger. You should not skimp on relatively cheap things if the well is not stable in terms of liquid level.