A well on the site of a summer cottage or a private house makes it possible to obtain clean water for technical and garden purposes. In some cases, wells are even suitable for providing residents with drinking water, but in these situations, special equipment is required to pump water out of them. Borehole pumps are a technique that you need to choose based on the characteristics of the well.

- The main types of pumps

- Types of surface equipment

- Self-priming pumps

- Pumping household stations

- Stations with ejector and injection elements

- Varieties of submersible models

- Vibrating pumps

- Screw pumps

- Vortex submersible pump

- Equipment selection options

- Equipment brands

- Installation and maintenance of pumps

- Device cost

The main types of pumps

The type of borehole pump affects its cost, as well as technical capabilities. There is a standard classification that divides units into 2 main types:

- Surface mounting technology. Surface pumps are installed 1-2 m from the well. Water in them rises upward due to rarefaction, and then is collected in a special container. However, it is extremely difficult to take water from a great depth - from 9 m or more - with such units. This technique works through a valve that prevents water from flowing back. Most often, surface models are used with a large vertical well. However, there is a separate subtype of surface pumps - household water stations. The main disadvantage of this species is the need for protection from precipitation and comparative noise.

- Immersion technique. Water equipment contains an engine and a working reservoir in one housing. Unlike ground equipment, it requires full immersion in the well. The technique is secured with special cables.

Each type of pump has its own subspecies. Understanding their features will help you understand how each of them works and for what conditions it is suitable.

Types of surface equipment

The action is triggered by muscular force applied by a person. Best suited for use with shallow wells. The water obtained by such a pump is suitable for irrigation and household needs. Manual unit design:

- cylinder;

- a piston that expels the liquid;

- air and water valves;

- lever to activate the piston.

A hand pump can be purchased in addition to electrical equipment and used when there is no power supply.

Self-priming pumps

The devices are suitable for operation in wells up to 10 m deep. Self-priming pumps are often equipped with a centrifugal element that pumps water from the source through a hose. However, you will have to constantly monitor the heating of the case, as they are prone to overheating.

To get rid of this problem, there are additional units that cool the pump. However, such equipment is still not suitable for a full-fledged water supply of a suburban area.

Pumping household stations

The station consists of a self-priming high-power pump and a hydraulic accumulator that maintains the required pressure. For automatic operation, pumping stations are equipped with control units that monitor performance indicators. Surface stations are suitable for wells up to 10 m deep.

Stations with ejector and injection elements

Suitable for working with wells with a depth of more than 10 m. Ejector and injection elements allow you to create an additional circuit with a reduced cross-section through which water passes and its speed increases. Such stations are ideal for working with wells up to 25 m deep. However, the equipment has some disadvantages:

- low productivity;

- loud noise.

The stations should be installed in a separate technical room that can reduce the noise level.

Varieties of submersible models

Like surface mechanisms, submersible ones are represented by such a variety as centrifugal installations. They consist of 2 elements: a surface motor and a submersible module. But there is equipment that is made in a sealed case and is immersed in water.

The centrifugal elements are suitable for working with wells up to 7 m and have the following design:

- body with 2 sets of branch pipes: intake and discharge;

- a coupling connecting the body to the drive;

- working mechanism with a shaft in the form of a wheel.

Internal combustion engines or electric motors are used. These models require the addition of water before use. They are distinguished by high reliability and ease of use.

Vibrating pumps

Another common type of submersible equipment is vibration units, one of the most popular is the Malysh pump. They are distinguished by their small dimensions, low power and minimal weight. However, such pumps easily perform the functions assigned to them, although they create a lot of noise.

Consist of the following elements:

- steel body containing all working mechanisms;

- a piston activated by an electromagnetic vibrator.

The technique is very easy to use, it does not need specific maintenance. However, these pumps are not suitable for wells with sand, as they begin to wear out quickly and break.

Among the advantages of vibrating pumps is the ability to use in heated and alkaline liquids. It is important to use such units only away from other equipment that could be affected by strong vibrations.

Screw pumps

This variety is suitable for use in polluted water. Neither centrifugal nor vibration models are so well suited for this purpose. Screw units work according to the following principle:

- the broaching screw auger takes water;

- then it is distilled through a hose into the tank.

The design of the pumps is created in such a way that fine debris and sand do not penetrate into it during the distillation of liquid.

Submersible screw pumps are the only equipment that does not suffer at all from the polluted environment. With their help, you can distill dirty liquid into tanks and purify it using additional methods.

Vortex submersible pump

The vortex equipment is equipped with a wheel with paddles along the edges, which ensure the movement of water from the branch pipe to the outlet. The pressure in the equipment gradually increases, and the fast operating speed creates a vortex of fluid. After the liquid leaves the nozzle, it is pushed upwards into the reservoir in which it accumulates.

Even with a low head, vortex pumps provide high pressure, which is the main advantage of the technology. Therefore, it is reasonable to use a vortex unit in wells with a minimum water level. However, it is impossible to use them in polluted conditions.

Most of the models of vortex units are designed to work at a depth of up to 30 m, but there are also more advanced options that raise water from a depth of up to 100 m.

Equipment selection options

- Water consumption. You can see the characteristics in the equipment passport. Before buying, you need to set the dimensions of the well: diameter, height of fluid rise.

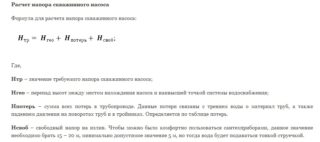

- Water supply pressure.The value is indicated as the height to which the water is supplied. For the choice, it is necessary to take into account the height difference between the points of the well, the amount of pressure for the independent outflow of water, the loss in conjugation of other elements of the channel. The numbers are summed up using the formula.

- Immersion depth and source diameter. These indicators will affect the brand, the level of immersion of the equipment, as well as its suitability for use in a particular soil.

There are several well-known well pump manufacturers that deserve attention.

Equipment brands

The industry leaders include the following manufacturers:

- Italian brand Aquario - manufactures industrial and household equipment;

- Wilo is a German company that has been selling pumps since 1872 and has earned worldwide recognition;

- Aquarius is a Ukrainian brand that has been producing excellent equipment for water transportation since 1995;

- Dzhileks - a corporation near Moscow that has been manufacturing pumps since 1993;

- Pedrollo is an Italian factory that has been producing electric pumps since 1974;

- Vortex is a Russian brand with unsurpassed quality, has been operating since 1974;

- ESPA is a Spanish corporation that has offered the world many innovations in pumping technology.

The choice of brand depends on the type of pump used, the required power. As for the country of origin, all these companies offer equipment of excellent quality.

Installation and maintenance of pumps

Installation of submersible electrical equipment in most cases can be done on your own. It is enough to follow the instructions: the apparatus is immersed in the mine on a special cable and fixed. However, experts do not recommend using a cable in plastic. An electric cable is installed next to the cable.

A more sophisticated technique that does not sink into the well requires stationary installation. For it, you need to create conditions that protect from direct sunlight and water.

Device cost

In online stores, prices for water pumps for a well differ significantly from each other. This is due to the type of equipment, brand, technical characteristics.

Automatic models of high pressure pumps can cost 40-50 thousand rubles and more. Submersible borehole pumps cost from 5,000 rubles.