Well construction only half solves the problem of water supply at home. Pumping equipment must correspond to the flow rate of the source, at the same time there is no need to overpay for excess power, because the devices consume electricity. The principle of operation of units pumping water also affects the performance of the well - there are models that are not recommended to be installed in a narrow casing, as they contribute to the silting of the filter. The selection of a downhole pump is carried out according to certain criteria.

The principle of operation and design of pumps for water wells

There is a wide range of pumping equipment models on sale. You may think to buy the cheapest pump, but it is recommended that you first understand all the modifications of the devices in order to choose the one that is suitable in all parameters:

- no unnecessary energy consumption;

- no negative impact on well operation;

- the presence of a protection function;

- suitable size and performance.

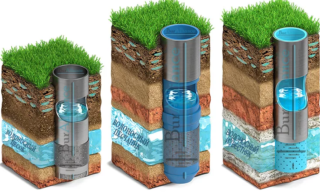

All pumps for wells and wells are divided into submersible and surface. In the first type, the sealed housing is in working order under water and is cooled due to it. Models are available with bottom and top water intake. For a well, it is better to choose with the top one, as this avoids clogging. Sludge or dirt can accumulate at the bottom of the well, which gets into the body and will take the unit out of working condition. If the liquid level in the source drops significantly, the pump installed at the very bottom will work until the dry-running sensor is triggered. Equipment with a lower water intake is used for maximum pumping of liquid from flooded areas - basements, lowlands. Sometimes such models are used to clean the source from bottom sediments.

Surface equipment is installed next to the well - on a concrete pad or in a caisson. The housing is separate from the suction element - hose or pipe. The most common type is a pumping station with a hydraulic tank. There are models without a storage tank, for which you can separately purchase a tank of any volume. The disadvantage of the station is that it does not pump liquid from a depth of more than 8 meters, therefore, before choosing a unit, it is necessary to know the distance to the water mirror, as well as the length of the horizontal line.

According to the principle of operation, there are about 25 types of pumps, but only those that pump clean water without solid inclusions are suitable for wells. There are equipment that better cope with viscous liquids, water containing solids or toxic substances. For such purposes, disposable cheap mechanisms are produced, which are disposed of immediately after completion of work.

Varieties of submersible pumps according to the principle of operation:

- centrifugal;

- vibrating;

- vortex, as a kind of centrifugal;

- inkjet.

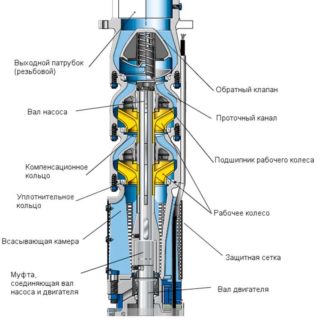

Centrifugal devices

Centrifugal aggregates are the largest group. The fluid transfer process takes place thanks to the blades mounted on the working shaft. The water moves progressively along the walls to the outlet, and an area of reduced pressure is created in the center. The performance of the unit depends on the impeller size and speed.To increase power, manufacturers produce multistage units that are small in size but do a good job.

Centrifugal pumps can be vertical or horizontal. The vertical ones are capable of pumping liquid with sand and stones. There are double suction models in which water comes from both sides - they are more efficient than one-sided ones. You can choose a device with a wet or dry rotor. In the first case, the rotor is in water, which lubricates and cools it; in the second, there is no contact between the rotor and the liquid. The former do not make much noise during operation, while the latter require a separate room, preferably with soundproofing.

Advantages of centrifugal pumps:

- long service life;

- simplicity of design;

- low cost;

- reliability;

- do not silt the well.

The disadvantages include increased demands on the purity of water and low productivity.

A type of centrifugal unit is a vortex pump. Their main difference is the fluid flow. In a centrifugal flow, the flow passes along the walls of the body, in a vortex - along the axis.

Vibrating pumps

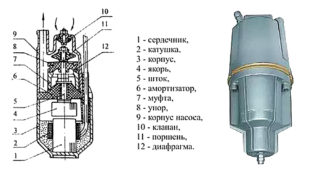

Refers to a subspecies of piston devices. Liquid pumping occurs due to the change in pressure that the piston creates. Water is sucked into the working chamber during the low pressure interval and expelled as it increases. The translational movements of the piston occur at a frequency of about 50 times per second.

Benefits:

- there is no need for frequent inspection and lubrication of parts, since there are no moving parts inside;

- high wear resistance due to the lack of heating;

- work at any temperature of the pumped liquid;

- salts and other dissolved substances do not affect the operation of the device.

Disadvantages:

- not suitable for wells, as vibration enhances the movement of sand and clay, which subsequently settle on the filter and clog it;

- possible full immersion in the sand and stoppage of work.

Vibrating pumps are more often used in wells or for cleaning a well from bottom sediments. If a newly constructed well needs to be pumped, vibratory equipment does the job well.

Jet pumps

The absence of moving parts makes such units durable and reliable. Among the disadvantages is low efficiency. When compared with vibratory or centrifugal ones - only 30%.

The principle of the jet pump is used in the ejector mechanisms of pumping stations, which increase the depth from which the station can lift water. With the help of an ejector, it increases to 12 - 15 m, although this device is expensive.

Main selection criteria

To choose the right pump for a well, you need to know exactly at what distance the water mirror is. Surface aggregates work up to 8 meters. Submersible are designed for deep sandy and artesian wells.

It is necessary to pay attention to protection sensors - from overheating, idling and voltage surges. Such nuances increase the service life of pumping equipment if the water in the well suddenly went down, which is more typical for Abyssinian and sandy sources. In artesian wells, the water level is always the same, but such wells are very rare due to the high cost of drilling and a huge package of documents.

Before buying a device, you need to calculate the approximate water consumption per day for each family member and choose the right power.

The head is one of the main and important characteristics of the unit. If the pump is located near the house, the horizontal length is not taken into account. If a long line leads to the well, every 10 meters horizontally is counted as 1 meter vertically.

Rating of the best models

Domestic models are also popular among the population, but they are much cheaper. In the ranking of borehole pumps made in Belarus, the first place is occupied by the Rucheek brand, which produces inexpensive but high-quality units, which have recently been conquering the Russian market.

You should be careful about Chinese goods - there are no quality ones among cheap ones. Expensive Chinese pumps are durable and reliable, as they are made of durable materials.

The cost of pumping equipment

The cost of devices is primarily influenced by the manufacturer's brand. Well-known firms offer goods at a higher cost, although such quality can be found much cheaper.

Technical characteristics - power, height of the water column, the presence of protection sensors, energy class - increase the cost of pumping equipment.

The materials for the body and internal parts are an important indicator that is worth overpaying for. For example, if the pumping station is located in a cold room, condensation will begin to accumulate on it, so the housing must be well protected from moisture. A plastic submersible pump will not last long, so self-respecting companies produce such models only in stainless steel. It will cost more, but less money will be spent on repairs.

To the cost of the pump, you need to add a high-quality cable and fasteners that will withstand the weight of the product. Otherwise, it may break off and fall to the bottom.

Owner reviews

Natalia. We made a hole in the sand and the first pump was a vibrating Kid. But after a year, the water began to flow poorly into the house, sometimes it was dirty in the morning. Didn't know what was the matter. An engineer was called, he advised to remove vibrations that "muddy" the water and clog the filter. I had to buy a centrifugal Pedrollo. It cost more, but the well has been operating normally for 4 years now.

Anton. I advise you to buy imported ones, since everything is fine with a guarantee. They took a pump from a Ukrainian manufacturer, it almost came to court, because they do not want to fulfill their obligations, they evade for any reason. I do not advise.

Alexander. They advised in a provincial store a "good" Chinese pump, not cheap. As it turned out later, the same one in the supermarket costs three times cheaper and cannot be repaired. He worked for 4 months, the guarantee is fake. They took it back to the seller and gave it away for free - let him use it himself. We specially went to the regional center and took German, but before that we studied half of the Internet in order to ask smart questions and no longer fall for "businessmen".

Elena. Our water is high - 2 meters to the mirror, so a pumping station was installed 5 years ago. For all the time there was not a single breakdown. Italians do well. We overpaid for the sensors, but they were not useful, they never worked.

Michael. I sit, read reviews and laugh - 4 months, 5 years. Aquarius has been working with us for 12 years. Repaired, or rather cleaned once. Domestic device, but made conscientiously. And China only needs to buy in large supermarkets and only expensive models - there is a chance that it will serve.