Arrangement of a private source (well, spring or well) includes the installation of special equipment for transporting water to the house. More often, craftsmen prefer to use a vibration pump with a lower water intake or an upper one. This small device has good performance and a good price. More often choose the pumps "Kid" or "Trickle".

Device and scope

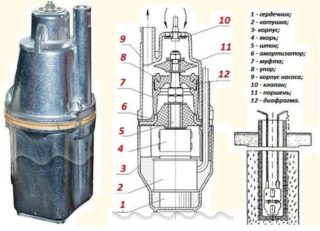

To understand what this small well / borehole unit is, you need to master its design. The pump consists of the following parts:

- Power element. This includes the core and coil. In tandem, they form a magnet. The core is placed in a silica sand and epoxy environment. The first removes heat energy, and the resin provides insulation from the winding from water.

- Vibrator. It is a magnet connected in series with the rod and shock absorber.

- Coupling. It is localized immediately behind the shock absorber and protects the electrical component of the pump from the negative effects of water.

- Injection chamber for taking fluid from a well or well. From it, the water is further transported upward through a hose.

- The piston is rubber. It is fixed on the rod and provides pressure drops in the working chamber (injection and vacuum). The movement of the rubber piston is slightly limited by the stop, which is located between it and the clutch.

- Inlet valve. It changes its position depending on the pressure in the working chamber. When it falls, the valve opens. When increased, it closes. At the top of the pump is the same valve (outlet). It works in the opposite way. When the pressure rises, it opens. When it goes down, it closes.

Due to its simple structure, small size and optimal performance, LEL is used in such cases:

- watering of orchards to get a good harvest;

- pumping out water from flooded premises;

- supplying liquid from a well or well to an autonomous water supply system;

- filling the pool with water;

- car wash in the yard or carpet washing, etc.

LELs are devoid of rotating elements, which means that the device does not need to be lubricated. For a submersible vibration pump with an upper water intake or with a lower one, water itself acts as a lubricant.

The principle of operation of the LPS

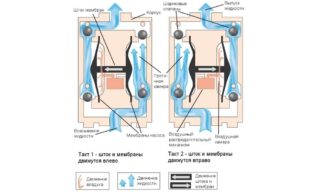

The operation of a vibrating submersible pump is based on pressure drops in the working chamber. It looks like this:

- The pump connected to the network provokes the coil winding to action, that is, it creates an electromagnetic field.

- It, in turn, pulls towards itself a vibrator located in the discharge chamber.

- The diaphragm is bent, which provokes a pressure drop in the working chamber.

- The inlet valve opens and water flows into the reservoir.

- As soon as the container is full, the pressure rises again, the valve closes, and the water goes up the pipe.

The frequency of magnetization / demagnetization fluctuates within 100 times per second. As a result of this work, vibrations arise, thanks to which the pump got its name.

Submersible Vibration Pump Modifications

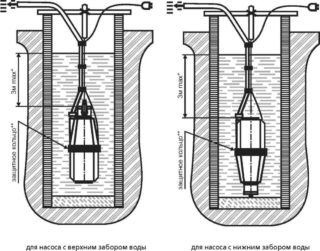

All vibratory pumps are classified into types in several categories. By type of water intake:

- Bottom fluid injection. The valve is located at the bottom.

- Upper water intake.Here, the inlet valve is located at the top.

By the number of valves, the LEL is divided into single-valve and two-valve. The second option has more power and performance.

Moreover, all NPS can be made of durable plastic or aluminum.

Vibratory submersible pumps are also classified by manufacturer into domestic and foreign. Of the domestic ones, the most common: "Aquarius" (aka Poseidon), "Kraton", "Stavr NPV 300", the HMS "Malysh" pump with built-in thermal protection, the "Trickle" technopribor, etc.

Criterias of choice

When choosing an NPS, it is recommended to be guided by the following criteria:

- Depth of immersion of the pump. The recommended values for a specific model are compared with a constant average water level in the source.

- Pump performance. It should be slightly less than the debit of the well / well. Productivity is measured in liters over a specified period of time.

- Height of water rise and its transportation. This parameter, among others, is indicated in the technical specifications for the unit.

- The diameter of the device body. Especially if NPV is purchased for a well. The section of the pump flask must be less than the diameter of the casing, otherwise the unit will not enter it.

It is advisable not to operate a vibrating submersible pump for water with a temperature above 35 degrees.

LEL installation stages

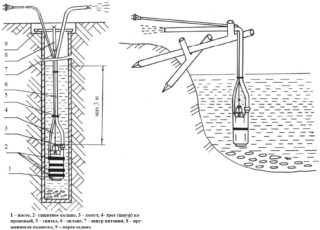

To install a pump in a well or well, it is necessary to perform work in the following sequence:

- Welding a solid metal frame on which the unit will be fixed. The frame is installed on top of a well or casing.

- Stretch the hose / pipe and the electric cord from the pump parallel to each other on the ground.

- A valve is attached to the inlet of the IVC, and a sleeve is attached to it.

- The latter is connected to a water supply pipe.

- The electrical cable is attached in parallel to the pipe using clamps. The wire should not be too taut, its slight sagging is permissible. Clamps are used to secure the cable. You can also use electrical tape, but it is less reliable. Over time, pieces of it can get into the water and clog the pump.

- A nylon safety rope is additionally fixed to the NPV. It is on it that the unit will hang. It is better not to take a steel cable, as it rusts over time and becomes unusable. As a result, a breakdown of the unit may occur.

- Holding the pump by the safety rope, it is lowered to the desired depth and fixed to the frame. An electric cable and a pipe are also attached here.

It is forbidden to hold the LEL by the wire when immersed.

Advantages and Disadvantages of Submersible Vibration Pumps

All NPS have a number of advantages and disadvantages. The pluses include:

- optimal performance;

- the possibility of pumping dirty water with admixtures of sand, soil and other fine debris;

- elimination of overheating when working in cold water;

- reliability due to the absence of complex nodes in the device;

- favorable cost;

- service life up to 10 years.

The disadvantages include:

- Pump intolerance to idling. If the water level in the source drops and the unit works like this for at least 5-25 seconds, it will fail.

- Sensitivity to voltage surges. Even if it changes downward by 10%, the pump will not work efficiently. With a net of tension, the LEL parts wear out many times faster.

- Wear of rubber elements. Especially in sandy water.

- Unscrewing all threaded connections. To prevent this from happening, it is better to replace them immediately.

As a rule, the wear of rubber parts is not critical. It is enough just to replace them yourself, and the unit will pump water again.

With proper operation and taking into account all the operating parameters of the unit at the time of purchase, the pump does an excellent job of supplying water to a small country house with a family of 2-3 people.