In areas where the depth of the well or well does not exceed 10 meters, surface pumping equipment is installed. Units differ in design, power, method of pumping water. Based on these features, as well as taking into account the characteristics of the source, the appropriate units are selected.

Scope and device of surface pumps

Surface pumps, unlike submersible pumps, are located near a water source. Their body does not come into contact with the liquid, it enters the points of consumption through the inlet pipe.

The devices are used to deliver water to the house, to drain the basement after a spring flood, to pump out liquid from the pool. It is possible to use it for irrigation of a land plot - in this case, the pump is placed near the reservoir, and the hose is lowered into the water. Almost all devices are powered by electricity, so the power cable needs to be long.

An important point is that the depth of the well should not exceed 10 meters, since all surface pumps have low power. Most often, at this depth, groundwater lies, which accumulate harmful substances from neighboring septic tanks. Mineral fertilizers are also washed out by rains into these reservoirs, so additional filters are installed in front of the house.

A surface pump will not work if an artesian well is equipped on the site, the depth of which can exceed 30 meters. In such a situation, you need to buy submersible equipment that has more power and is capable of pumping liquid from such a depth.

Classification by design and principle of operation

- self-priming surface water pumps;

- normally absorbent.

The first type does not require complete filling of the system with liquid before starting. Water is poured only into the body of the device. The rise is carried out due to the low pressure zone.

For the second type, you need to completely fill the system with water - the body and pipes. Sometimes the check valve interferes with filling the liquid completely, so they open the plug at the top of the device.

Surface pumps differ in the principle of operation, that is, the mechanism inside: centrifugal and vortex.

Centrifugal the units have a spiral casing, inside of which an impeller with blades is fixed. When the pump is driven, centrifugal force is generated. A rarefied space appears in the center, and a high pressure zone on the sides, which pushes the liquid into the pipe. Depending on how many impellers there are on the unit, it is called single-stage or multi-stage. The surface multistage pump is more efficient and powerful.

The design of a centrifugal pump consists of the following elements:

- a hose through which water enters the pressure pipe;

- hose transferring liquid to the internal working chamber;

- check valve so that water does not flow back;

- the filter at the inlet to the snail body prevents sand and other solid particles from damaging the internal parts;

- a device for monitoring the degree of rarefaction of the space in the center of the pump during operation - a vacuum gauge;

- a pressure gauge that measures the pressure when the liquid rises up;

- additional elements of shut-off valves that allow you to regulate the inlet and outlet flow.

Both surface and submersible models work on the principle of centrifugal equipment. Their disadvantage is low power and the inability to idle.

Combined units have impellers inside that combine the features of vortex and centrifugal types. Such designs are much more efficient in terms of efficiency.

Main selection criteria

The main criterion that is taken into account when installing a surface pump in a well is its depth. The optimal indicator is 8 m. Then you need to decide for what purposes the unit will be used. If you use it to irrigate a plot, you can buy a less powerful one, if you need to maintain an autonomous water supply system for a private house, you need a pump with a capacity of 3 cubic meters per hour.

The next important indicator is the head of the water column. For a country house, the optimal value is from 30 to 80 meters. It is generally accepted that 1 meter horizontally equals 10 meters vertically. A pressure of 1 atmosphere can move liquid up to 10 meters.

The further the equipment is from the point of water consumption, the less depth it will be able to lift liquid. The formula 1: 4 works here, that is, one vertical meter is equal to 4 meters horizontally.

It is advisable to buy a tank for storing water so that the pump turns on less often. So you can increase the resource of his work. This unit is already provided in pumping stations, but its volume is small - up to 24 liters. Some masters independently connect the tank to the pumps using instructions and videos.

The voltage in the power grid plays a role. If it is unstable and often falls, they buy a more powerful device or install a stabilizer.

Installation and connection features

If the pump is planned to be used only in summer, it can be kept outdoors under a canopy to prevent rain from falling on the housing. Many people equip a pit or caisson near a water source. This requires additional costs and time: it is imperative to lay it on top with clay so that the precipitation does not flood.

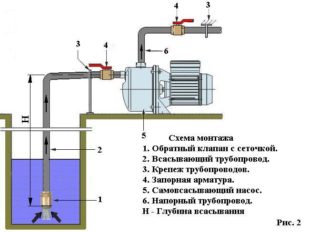

Connection diagram of a surface centrifugal pump:

- Connect a pipe with a check valve and a filter, which is planned to be lowered into the water.

- The end is lowered into the well to the liquid level.

- Fill the system with water. It is necessary that all air locks be excluded.

- Connect the pump to the network.

- Connect an outlet pipe or irrigation hose.

You can turn on and test the device.

Advantages and Disadvantages of Surface Pumps

The advantages of this type of equipment include:

- low weight and dimensions;

- easy installation that can be done by hand;

- safety in operation, since the power cable does not come into contact with liquid;

- long-term operation, especially for a surface pump with dry running protection;

- high enough efficiency to provide water for all needs.

The disadvantages include:

- sensitivity to solid inclusions;

- high noise level;

- limited source depth;

- the need for additional actions - filling the system with water before switching on.

You can choose an imported or domestic pump, depending on budget capabilities and operating goals.

The cost of the device is influenced by the availability of safety functions, performance and power indicators. Units made of durable materials - stainless steel or cast iron - are more expensive. Models in a plastic case are cheaper, but it is better to keep them indoors to avoid mechanical damage. You should beware of buying devices where cheap materials are used as electrical winding, which melt and burn when overheated.