Autonomous water supply in suburban areas is a modern approach to providing water to facilities located far from centralized networks. At the heart of the water main is a pump. Three types of it are used: deep, submersible and surface. The latter is used more often because it is easy to use. But such a pumping unit has a small water intake depth. To increase this technical characteristic, an additional element is used - an ejector. It can be installed in a pumping station, or it can be a separate unit - remote.

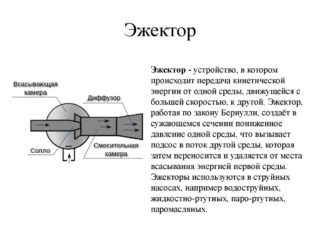

How the ejector works

- suction compartment, it is a chamber;

- mixing compartment;

- reduced diameter nozzle;

- diffuser.

Water moving at high speed inside the pipe creates a vacuum around itself. This gives the water flow an additional speed. To create a vacuum, a high water velocity is required. It is created by a pumping station.

The ejector is connected to the pump with two pipes or nozzles. Through the first pipe, the pump simply draws in water. Then, through the second pipe, he returns part of the liquid back to the ejector. This water passes under pressure through a nozzle with a reduced opening, where its speed increases several times.

Moreover, in the first case, the pump with the ejector is connected by two pipes, which increases the consumption of materials, but not much. In the second, from the pumping station, only one pipe is lowered into the water intake source.

The ejector has one more serious plus. It works as a stand-alone item. For a short time, he can independently pump water. This protects the pumping stations from dry running.

To regulate the volume of the recirculated water flow, as well as its speed, a conventional tap is installed on the return pipe loop. When partially closed, the volume and speed decrease, the efficiency of the device and the depth of the water intake decrease.

Built-in or external

The location of the device affects the installation of the pump and the efficiency of its operation.

It is easier with pumping stations with a built-in ejector. Their installation is simple and economical. The device itself is on the surface, which means it is easier to control, maintain and repair. It takes up little space, so it doesn't bother anyone. The device is installed in the station housing, therefore it is well protected from contamination. There is no need to install additional filters to protect it from sand, silt and small stones.

However, this arrangement does not give the maximum technical and operational characteristics. Pumps with a built-in ejector can lift water from a depth of 10 m. Maybe even lower, but then the head and productivity of the station are reduced.

Another disadvantage is the noise from the operating unit. The sound of the water moving inside the ejector is added to the pump noise. They are not strong, but they are well picked up by the human ear. Therefore, when installing a pumping station with a built-in ejector, you should consider a sound insulation system.For example, install a hood over the equipment, mount it in a utility room or in a caisson, but not inside the house.

Detail models in terms of material consumption and installation are more complicated. But other pluses outweigh minor flaws.

- The pump can lift water from a depth of up to 40 m.

- No noise is heard from the ejector.

If you compare the two varieties in terms of efficiency, built-in is better. Taking into account the depth of the water intake, preference should be given to the external model. Since the water located at great depths is cleaner, it is recommended to purchase pumping stations with built-in accelerators.

Features and rules for connecting pumping stations

Equipment with a built-in ejector is connected to an autonomous water supply network as standard. A pipe is connected to the suction pipe, which is lowered into a water supply source. To the outlet pipe - a pipe going into the house.

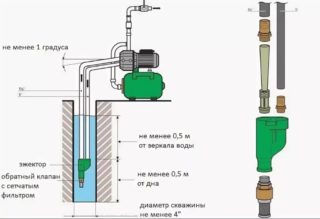

Installation of a pumping station with a remote ejector is carried out according to a more complex scheme. The entire assembly is carried out on the surface, and then the finished assembly with pipes is lowered into a well or well.

- The suction hole of the ejector is connected to a small pipe, into which a check valve is pre-cut, and a mesh filter is installed at the bottom.

- On the opposite side, a pipe (hose) is connected to the outlet, through which the water will rise to the pumping station.

- Another pipe is connected to the second hole (recirculation).

- The ejector with pipes is lowered into the hydraulic structure.

Both pipes are connected to pumping equipment. The first to the suction pipe, the second to the tee, which divides the water flow into two circuits: inside the house, down to the ejector. On the last circuit, a tap must be installed near the tee, with which it will be possible to regulate the speed of water movement.

The regulating tap works like this: the more it is closed, the more water will flow into the domestic water supply system. If the load on the water supply network has increased, then you can open the tap more, distilling the water down to the ejector. Ejectors with an automatic regulation system appeared on the market. Using them, you can refuse to install the crane.

During the installation of the remote ejector, the main thing is not to confuse the pipes, more precisely, their connection to the pumping station. One of them is somehow celebrated. For example, the outer end, which will connect to the pump, is painted or wrapped with electrical tape.

The advent of the ejector has solved many of the problems. There is no need to purchase expensive submersible pumps. Now it is possible to use surface installations for water intake from wells. But one must also take into account the fact that pumping stations are not self-priming equipment. Therefore, before starting work, they must be filled with water through a special hole in the housing.