A pumping station is a special set of equipment with the help of which water is taken from a well or well. The units included in its composition, if necessary, activate the replenishment of stocks and turn off the devices at the right time. It is not difficult to assemble a modern pumping station with your own hands if you follow the recommendations of the masters.

System design

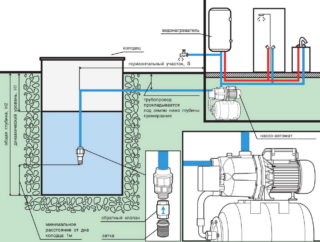

This system includes many elements:

- Pump. Surface or submersible is used. There are ready-made stations with centrifugal electric pumps on the market.

- Hydroaccumulator. It looks like a metal container of a certain volume, equipped with a special elastic membrane. The accumulator prevents water hammer, as it reduces the pressure when the water flow is suddenly stopped.

- Coarse and fine filters. They rid the water collected from a well or borehole from sand, silt.

- Pressure switch. The unit automates the functioning of the pumping station, prevents the system from running dry.

- Pressure gauge. The device is necessary to monitor the operation of the pumping station, allows you to quickly identify leaks.

- Dry running relay. It is used in conjunction with borehole pumps. Turns off the device when there is no water in the system.

In the standard scheme of the pumping station, there are sanitary fittings. These are a variety of valves, taps, couplings, tees, hoses. There is also a check valve in the system. It prevents the outflow of water when the pressure drops or when the pump stops.

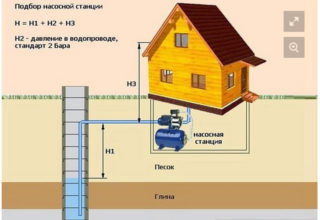

Criteria for the selection of elements for a pumping station

Appointment

Pumping stations can be domestic or industrial. The latter type of equipment is used to meet the needs of manufacturing enterprises. Their performance characteristics allow pumping large volumes of water. Only professionals can assemble and install industrial-type pumping stations. Home installation is possible when using household systems.

Source type

If the system is planned to be used exclusively for economic needs, it is allowed to choose a natural or artificial reservoir as a source. When the pumping station will be used to obtain drinking water, it is imperative to organize a well or a well.

For open reservoirs, shallow underground sources, surface-type pumps are chosen. For wells, submersible units are purchased.

Working hours

The pumping station is connected to a water source and operates in manual or automatic mode. The user, depending on his needs, can choose a stationary or mobile model. You should also consider the throughput of the equipment. It is generally accepted that to meet the needs of one person, you need 250 liters of water per day.

Choosing a location

It is allowed to install a pumping station in a private house with your own hands in the basement, in a separate building or caisson. When choosing the first option, it is important to adhere to several conditions:

- the equipment should be located in the basement of the house at a level at which it will not be damaged by the rise of groundwater;

- it is necessary to prevent contact of the pumping station with the walls of the basement;

- the room where the equipment is installed must be heated, this will prevent water from freezing in the system during the cold season.

When using a sump for a pumping station, it is important to make it insulated. The installation of equipment in the caisson is carried out at a depth that is below the level of soil freezing. It is recommended to make a pit in the source headband. A well is dug around the casing, the bottom of which is covered with rubble or filled with a screed. The walls of the caisson are made of brick or reinforced concrete.

When choosing a separate room for installing a pumping station, you can solve the problem of noise insulation. But this option has many disadvantages - the presence of additional difficulties in maintenance, the need to insulate the water pipes suitable for the house.

Installation steps

To install a pumping station, it is important to properly prepare the base. The equipment vibrates during operation, so it must be secured. The base can be made in the form of a concrete slab 10-15 cm thick. It is recommended to make sand preparation under it. Before pouring concrete, a reinforcing frame is installed on the pillow. The base is allowed to be made of several rows of bricks. Also, the pumping station can be placed on a wooden panel. In this case, it is necessary to additionally provide for the presence of shock-absorbing pads to damp vibration. The wooden board should be placed on beams 10 cm thick.

A pump, a storage tank, and a control unit are placed on the finished base. These elements are interconnected by pipelines. If there is a concrete floor, rubber pads are placed under the equipment supports. They dampen vibrations and prevent premature wear of the instruments.

To make a station with a submersible or surface pump, after installing the equipment, it is connected to the existing water supply system and to the head of the well. Be sure to install a check valve and a shut-off valve. All nodes and connecting sections are carefully sealed.

After the completion of the installation work, a test start of the system is carried out. Open the shut-off valves and turn on the electric pump. In a functioning system, the pressure reaches 1.5-3 atmospheres. The parameters for stopping the operation of the pump can be adjusted using the automation unit.

Common installation errors

When assembling a pumping station, it is necessary to avoid the following mistakes:

- Installation of filters before the pump. Filters have a tendency to clog, which can cause the unit to idle.

- Incorrect mains voltage. If there are any faults, it is recommended to additionally install a stabilizer.

- Inconsistencies between the accumulator and the pump. Leads to excessive consumption of electricity and premature equipment failure.

- The use of an inlet pipe in front of the pump of the wrong diameter. In this case, the efficiency of the equipment decreases.

It is important to check the pressure in the accumulator after starting and adjusting the work. This operation should be repeated regularly at intervals of once a year.