When arranging a source in a suburban area, it is not enough to drill it. It is necessary to select, purchase and install all the necessary components for the well so that its operation is complete and uninterrupted. At the same time, the equipment must be selected in accordance with the technical characteristics of the hydraulic structure itself.

Well accessories

To fully equip the autonomous water supply system, the master will need:

- pump;

- hydroaccumulator;

- caisson (upper protective chamber);

- headband.

Of the additional components, with the help of which the operation of all units will be more productive, a pressure gauge, a pressure switch, and a check valve are distinguished.

Pump

The injection unit for the well can be surface or submersible, deep. It all depends on the parameters of the source. For wells up to 12 meters deep, surface equipment can be used. You can enhance its capabilities using an external ejector. Then it will be possible to raise the water from a depth of up to 18 m. When using a surface pump, the intake hose with a coarse filter installed at the end is simply lowered into the hydraulic structure.

For sources with a depth of 20 m or more, it is better to take a submersible deep device. Such units have the form of a narrow flask, which is located in the casing of the well.

All pumps for a self-contained source with casing are classified according to the following parameters:

- power - from 600 W and more;

- productivity - from 1.5 m3 / hour;

- head - 8 m or more;

- immersion depth - 8 m and more;

- manufacturer.

Centrifugal aggregates are mainly used for wells. Vibrating ones are not recommended, as they tend to destroy the casing and, in parallel, stir up the sand from the bottom.

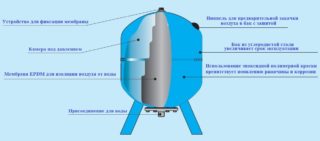

Storage tank

He's a hydraulic accumulator. With the help of such a device, it is possible to maintain a constant pressure in the system. And in the event of a temporary power outage, the family has a supply of water for several hours.

The accumulator is a stainless steel tank. Its inner part is divided into compartments by a rubberized membrane. It is she who regulates the cycles of turning the pump off by changing the pressure in the tank.

Accumulators can be classified by volume (from 24 liters or more), material of manufacture and manufacturer. For a family of 2-3 people, a 50 liter tank will be enough. The storage device is connected to pumping equipment.

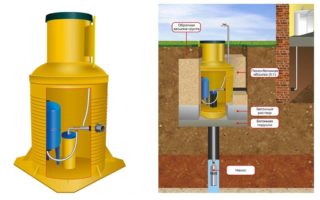

Caisson

This is a protective chamber that allows you to protect the upper part of the well from freezing in winter and to place all the working units of the pumping station in one place. Thanks to the caisson, the source and all equipment are reliably protected from atmospheric precipitation, small debris, and vandals.

The camera can be made with your own hands from various materials - concrete mortar, reinforced concrete rings, brick blocks or metal. Or you can just buy a factory plastic caisson. It weighs less, is completely sealed, and has stiffening ribs. The installation of such a camera can be performed without the involvement of special equipment, which will have a positive effect on the master's budget.

The parameters of the caisson should be at least 0.8 x 0.8 m.In this case, it is advisable to place the upper part with a hatch so that it is located 15-20 cm above ground level. This prevents atmospheric water from leaking into the chamber.

If the caisson is not provided (for example, the well is located in the basement of the house), you can plug the upper part of the casing with a head. It is a polymer cover with technical openings for the outlet of the water inlet hose and cable. On the underside of the head there is a special carabiner for attaching the pump's safety cable.

Component selection criteria

The equipment necessary for the well is selected according to various parameters, corresponding to a specific device.

The caisson is selected by size, volume, wall thickness, material.

The pump is chosen according to the following criteria:

- manufacturer (the most popular are Dzhileks, Grundfos, Malysh, Trickle);

- power;

- productivity: it should not exceed the flow rate of the source, otherwise the pump will quickly drain it;

- immersion depth;

- pressure;

- type (vibrating, centrifugal).

As for the accumulator, the main criterion for its selection is volume.

Equipment installation stages

When installing pumping equipment for wells, all actions are performed in a strict sequence. As soon as the casing is installed and the well is completely rocked, the installation of the caisson is started.

A pit is dug around the source to a depth of 1.5-2 meters (below the level of freezing of the soil). It is important to prepare the base for the camera device. Especially if it is concrete. Around the perimeter of the pit, a concrete pad should be poured and reinforced with a mesh. Under the polymer caisson, it is allowed to simply pour a sand cushion with a layer of 10-15 cm and tamp it well.

The walls of the chamber are displaced from concrete mortar, bricks or rings. When working with reinforced concrete elements, make sure that they become even. All joints are reliably sealed.

The installation of a polymer caisson is performed as follows:

- A hole is formed in the lower part of the chamber, equal to the diameter of the casing. They put the caisson on the column and carefully lower it to the bottom. The junction of the tank and pipes is well sealed with bitumen mastic.

- Technical holes are formed in the side walls of the caisson for the outlet of the pipeline. It is also important to use a good sealant here.

As soon as the protective chamber is installed, it is backfilled, compacting the soil well and layer by layer.

Installing the pump

When installing a surface unit, the work scheme looks like this:

- The pump is mounted on the bottom of the caisson next to the well. Its feet are screwed to the floor to eliminate excessive vibration.

- A water intake hose is attached to the inlet pipe using fittings. Its lower part is equipped with a coarse filter. The length of the hose is calculated in such a way that it does not reach the bottom of the source 1-1.5 m.

- The sleeve is lowered into the well, having previously provided it with a load, in order to exclude chaotic movement in the water during operation.

If a submersible pump is installed, the installation principle looks like this:

- On the ground, an electric cable, a safety cable and a water intake pipe are unwound in parallel. They must all be the same length.

- A water intake hose is connected to the pump outlet pipe using a fitting. A check valve is fixed about a meter away from it.

- The pump is attached to a safety rope. It is advisable to take a durable nylon. Steel eventually deteriorates due to the negative effects of moisture.

- All three elements (cable, wire rope and pipe) are tightened with construction clamps in 1 m increments to prevent tangling in the casing. It is important to avoid pulling.

- The other end of the insured cable is attached to the top-mounted frame or head carabiner.

The pump is slowly lowered into the well to the desired depth.

Hydraulic tank installation

The diaphragm tank is located directly next to the pump or in the caisson.The hose taken off from the submersible pump is connected to the accumulator. If the master mounts a surface unit, first a cut is attached to its inlet pipe, which is then joined to a hydraulic accumulator.

From the installed drive, a branch of the water supply is taken to the house.

It is also important to install a pressure gauge with a pressure switch here. Further, the hydraulic tank is filled with water through a technical opening (it is prohibited to connect it dry). Using a pressure gauge and a pressure switch, they regulate the optimum performance. The recommended lower pressure value is 1.5 atm., The upper one is 3 atm. Adjustment is carried out using special handles, on which arrows indicate the direction of their rotation.

If the pumping station works fully, turns on and off in accordance with the set pressure parameters, water enters the system correctly, which means that the well device is completed correctly.

After the accumulator in the direction of water movement, it is advisable to mount another check valve. It is also necessary to provide two drainage taps before and after it for possible conservation of the system or emergency drainage of water.

If the water from the well is highly mineralized, enriched with iron or other components, it is important to install a good treatment system in the caisson. Filters are selected after analysis of the liquid.

The cost of components

To fully equip the source, you will have to incur certain costs for the purchase of the necessary elements. Approximate prices for equipment for supplying water from a well in the Moscow region:

- surface pumps, depending on the manufacturer - from 2500 rubles;

- submersible deep units - from 5,000 rubles;

- factory plastic borehole caisson "Aqualux" - from 20,000 rubles;

- stainless steel hydraulic tank - from 3500 rubles;

- headband from 1600 rubles.

On average, the arrangement of an autonomous source will cost 50,000-60,000 rubles, provided that the work is performed independently. If an Abyssinian-type source (garden column) is drilled, the costs will be minimal.