Water from rivers, lakes, reservoirs and from the tap has the same physical structure of atoms and molecules, but the chemical composition is different. The results of numerous studies show that water is often unsuitable for industrial, household and, moreover, food purposes without preliminary treatment. The implementation of modern water treatment systems helps to solve the problem. They are divided into industrial and household, simple and complex, budget and expensive.

The importance of maintaining water treatment systems

The task of mechanical cleaning is to remove large and harmful particles from the surface of industrial reservoirs. Due to heavy loads, treatment plants must regularly undergo high-quality service, since harmful impurities settle on the parts.

In enterprises, as a rule, a complex system of liquid purification is installed. Thanks to this, it is possible to reduce the amount of fuel and electricity consumed, and to increase the volume of water reuse.

In everyday life, they use special nozzles for the tap, as well as pitcher filters. Their advantage lies in their compact size, ease of use, and reasonable cost. Careful and regular maintenance is required to ensure that the efficiency of the cleaning equipment is not compromised.

Regular testing of water treatment is required to obtain softened clean water for reuse in the heating and water supply communication network. Checking the condition and performance is carried out for the following types of equipment:

- units for ozonization and disinfection;

- disc, mesh and cartridge filters for coarse mechanical cleaning;

- ion exchange aggregates;

- reverse osmosis systems;

- installations of nano- and ultrafiltration.

Large companies that have proven themselves well, on contractual terms, carry out maintenance, replacement of parts and repair of water treatment structures.

Service maintenance of water treatment equipment

- Drawing up a plan for the frequency of work performed.

- Regular testing of the performance of the units.

- Full maintenance and equipment setup.

Service steps:

- Laboratory analysis of the chemical and biological composition and quality of water.

- Checking the pressure at the inlet to the system, correcting if necessary.

- Diagnostics of the work of the filling unit in containers with a special reagent.

- Maintenance of filtering equipment, regular cleaning.

- Restoration, including the care of filters, filling the required reagents.

- Visual control of equipment operation, full recovery of productivity and power in case of breakdown.

Express analysis allows you to assess the condition and quality of water by chemical and biological parameters. It also helps to calculate which part of the filter does not cope with the task at hand.

Low pressure in the pipes negatively affects the quality of fluid cleaning. The filling of water into the container should be carried out without interruptions and interruptions. After checking and repairing, make a test run and check the pressure.

Special companies have developed programs for equipment maintenance.

- Comprehensive diagnostics.The equipment is studied not only visually, but also instrumentally, which makes it possible to reveal obvious and hidden breakdowns.

- Technical supervision - regular diagnostics, reloading of filters and reagents. A full range of services is guaranteed after signing the contract.

- Replacement of filters, re-filling of reagents. During continuous operation, filters are the first to fail, since they bear the greatest load. The problem can be solved by regular cleaning or replacement of the filter, and the addition of chemicals.

If it was not possible to find the malfunction in a timely manner and eliminate it, they order repair services. Reconstruction is the preferred option for working but outdated plumbing systems.

Specialized organizations provide a full package of services of various levels of complexity. The program is compiled individually, depending on the preferences of the customer, for example, service is provided on an ongoing basis or one-time.

Most common breakdowns

Owners often turn to specialized workshops for the same breakdowns. In water supply equipment, the following working units usually fail:

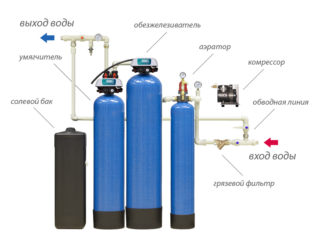

- A softener malfunction is a common breakdown when a large amount of salt deposit builds up on the surface of the reagent tank float switch. For this reason, the withdrawal of the reagent from the reservoir is not carried out, and the water remains dirty.

- If the degreaser does not function properly, a large amount of grease has formed on the inside of the control valve. As a result, the piston mechanism jams, the rings break, and the water is continuously discharged into the drain, or further spreads through the untreated pipelines.

- The aeration column stopped working - a high concentration of iron in the water leads to the clogging of the air relief valve. This leads to airing of the system or continuous discharge of water into the drain.

The cost depends on the type of service. The average price in Russia for a one-time visit of the master to establish the cause of the breakdown is from 2000 rubles. The cost of the annual scheduled accounting (4 visits within 12 months) - from 14,000 rubles.

If the equipment is outdated, but the load is heavy, it is recommended to give preference to routine annual inspections. The conclusion of such an agreement can reduce the costs of the owner of the water treatment equipment. However, you need to contact trusted organizations with a good reputation, otherwise the money will be wasted.

The optimal frequency of maintenance is once every three months, if there is no need for an extraordinary check and troubleshooting. The guarantee of the absence of serious breakdowns is a regular check of the condition and operability of the equipment, cleaning and replacement of filters.