Installation of an autonomous artesian or sandy source on the site requires further improvement of the water well after drilling. Such works allow at the same time to ensure the purity of the water resource, protect the well shaft from small debris entering it, prevent freezing of the upper part of the casing in winter, and also correctly install and connect all the necessary equipment at one point for the source to work. In addition, the upper chamber serves as a barrier to vandals. Thanks to a properly equipped well, the foreman is able to service the equipment at any time of the year, and, if necessary, carry out repair work.

Well construction options

One of several popular options can be used to refine the well (to correctly finish the upper part of the casing). Each master selects for himself the one that is more convenient, profitable in terms of finance.

Placement of a hydraulic structure inside a building

More often this option is used if the source was drilled on the site even before the construction of the cottage. In this case, the box of the house is driven out in such a way that the upper part of the casing is located in its basement. Ideal - in any farm building, greenhouse, greenhouse.

The advantages of such a well device are as follows:

- The top of the column is constantly warm. The source is not threatened with freezing.

- Fewer consumables are needed to bring the pipeline to the house. In addition, the smaller footage of the highway means the absence of cold bridges on the line.

- There is no need to incur additional costs for the installation of the caisson or other auxiliary premises for the placement of the pumping station.

However, this source location has a number of disadvantages:

- Loud pump noise. We'll have to soundproof the basement.

- The presence of moisture in the lower part of the house. The work of the source is associated with the constant movement of water. High humidity will not have the best effect on the box at home over time.

- Difficulty in carrying out repair or conservation work. Sooner or later, any hydraulic structure will become silted up. We'll have to flush it, swing it. It will be difficult to do this in the house. The same applies to backfilling the source after the expiration of its service life.

It is prohibited to install wells within residential buildings by SNiP. You can only make an Abyssinian well (igloo well).

Overground house

This is a good option for a well device. Especially if the site is spacious and on it you can dream up about the original landscape design. Externally, the pavilion can be made in the form of a fairy-tale hut. Inside, it is a slightly deepened (like a cellar) room with pumping equipment located in it.

It is desirable to deepen the pavilion just below the level of freezing of the ground. The device of such a technical house will definitely cost more due to the higher consumption of building materials.

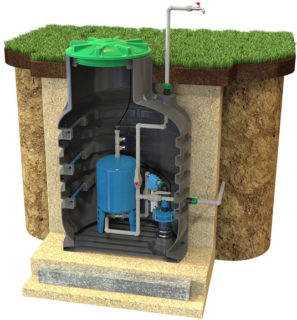

Underground caisson

This is the most optimal well construction option. The well deepens below the level of soil freezing. On the surface of the site, it is practically invisible if you provide for the decorative design of the hatch cover.In addition, there will be no noise from a working pumping station at all.

You can mount the caisson with your own hands from brick or monolithic concrete pouring. You can install a factory polymer camera. The second option is less laborious and financially costly. The exception is the volume of brick blocks remaining from the construction of the house. Then the master will have to spend energy on the construction of the caisson.

Making a camera from RC rings is unprofitable. You will have to bear the costs of transporting heavy elements and renting special equipment in order to lower them into the pit.

Preparatory work

At the stage of preparation, you need to purchase all the necessary equipment:

- a pumping station with a hydraulic accumulator, or a submersible pump for wells over 20 meters;

- pipes for laying water supply;

- sealant - bituminous mastic or roofing material;

- cement, sand and fine crushed stone;

- all adapters, fittings, stopcocks - they are calculated according to the previously drawn up water supply scheme.

Also, at the preparatory stage, you should prepare the necessary tool:

- concrete mixer;

- bayonet and shovels;

- tape measure, building level;

- ramming;

- Master OK;

- formwork boards.

The preparatory stage is also carrying out land works. It is necessary to dig a pit of the required parameters around the casing. A square chamber of 1.5x1.5 m will suffice. The depth of the caisson should slightly exceed the level of soil freezing. When digging a hole, it is important to take with a margin of 20-30 cm to the sides and in depth.

Installation steps

When building a brick or monolithic caisson, it is important to prepare a concrete base for them. To do this, first ram the bottom of the pit and pour a 10 cm thick sand cushion. It needs to be slightly moistened and well compacted.

- Four boards are placed along the walls of the pit for pouring the base cushion. A solution is prepared from cement, sand and crushed stone in a ratio of 1: 3: 5, diluting the bulk water to the consistency of thick sour cream. The finished solution is poured about 5-7 cm and a reinforcing mesh is placed in it. The rest of the concrete mixture is laid on top and allowed to dry completely. When pouring the cushion, it is better to wrap the part of the casing that will come into contact with the monolithic slab with roofing material or coat it with bitumen mastic.

- As soon as the base is completely dry, you can start installing the walls of the caisson. Do not forget about the gaps of 30 cm on each side of the earthen edges of the pit. Bricklaying is performed, after having laid strips of roofing material under it. The same must be done if a monolithic fill is to be made.

- The brick is laid starting from the corners. The concrete mixture is poured into the installed formwork. Moreover, it can be driven out at once to the full height from wooden boards or mounted in stages (30-40 cm each).

- When pouring, the monolithic walls of the caisson must be reinforced with a mesh.

- As soon as the camera is ready, it must be completely dried and coated with bitumen mastic on all sides.

- After that, the caisson is backfilled, layer by layer compaction of the soil. Instead of ordinary earth, you can use a cement-sand mixture.

The roof of the chamber is poured from a concrete mixture or is arranged from a strong wooden / metal shield with a hatch. The tree can be wrapped in roofing felt. Metal should be treated with anti-corrosion compounds.

Installation of pumping equipment

When installing the pump, it is advisable to tighten the cable of the unit, the safety cable and the water supply hose with clamps so that they do not get tangled, do not dangle in the source. The spacing of the clamps is 1-1.5 m. It is not allowed to stretch the cable or rope.

After installing the pump, install the hydraulic tank. It is connected to injection equipment and filled with water. At this stage, it is important to equip an autonomous source with pressure control of the accumulator.This is done using a relay.

The accumulator must be equipped with a check valve at the outlet. Here and at the entrance to it, it is advisable to mount drainage taps for the conservation of the system in the country.

Installing the head

A cap can be installed to completely seal the top of the source. The work execution guide is as follows:

- The top of the casing is thoroughly cleaned and covered with an anti-corrosion compound.

- A water supply hose and a pump electric cable are passed into the head cover.

- The flange and rubber ring are put on the pipe, having previously secured the safety cable to the carabiner at the top of the cover.

- It remains to put it on the casing and squeeze the fixing bolts.

As an option for arranging a well in warm regions, you can just do it with a head. If you equip the source in this way, you can incur a minimum cost.

Well completion cost

Price for the arrangement of a water well with a depth of up to 40 m in the Moscow region:

- carrying out land works - 1600 rubles;

- installation of a caisson (made of reinforced concrete rings, monolithic filling or polymer chamber) - from 12,000 rubles;

- installation of pumping equipment - 10,000 rubles;

- installation of a hydraulic tank and its connection - 5000 rubles;

- installation of the head - 2300 rubles;

- automation - 1000 rubles;

- piping for drinking water - 100 rubles / l.m .;

- commissioning works - 1,000 rubles.

If you refine the well with your own hands, you can save up to 20,000-30,000 rubles.