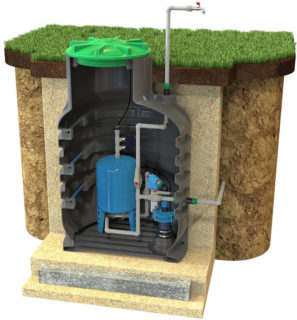

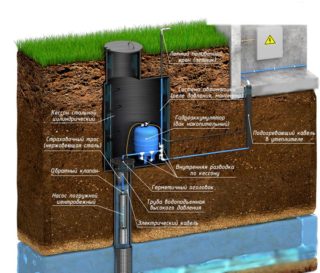

An autonomous source in a suburban area allows you to make life in the house comfortable regardless of the season. So that even at subzero temperatures water can flow freely into the cottage, it is advisable to complete the arrangement of the well with a caisson (a special protective chamber in the head area). It can be built from various materials - reinforced concrete rings, monolithic fill, brick, metal, plastic.

Advantages and disadvantages of the caisson

The protective tank is a chamber with dimensions of 1x1 m (minimum) with a depth below freezing of the ground. Installing a caisson for a well has the following advantages:

- the ability to compactly place in one place pumping equipment, automation, a hydraulic accumulator;

- reliable protection of equipment from vandals, precipitation, frost;

- preventing freezing of the water supply system;

- the absence of third-party noise of pumping equipment, which is inevitable when it is installed in the basement of the house;

- the ability to easily preserve the system for the winter using a drain valve installed in the caisson;

- Convenience of laying several pipeline lines for various tasks: watering, filling the pool, supplying water to a sauna, a cottage.

If there is a caisson, it is easier and faster to dismantle the submersible pump if you install a winch in the chamber.

Caisson requirements

The main requirement for arranging the caisson of the well for water is the absolute tightness of the chamber. Otherwise, the top water will periodically heat up the room, which will not in the best way affect the performance of the pumping equipment.

The rest of the caisson is chosen according to the following criteria:

- It is desirable that the depth of the chamber be greater than the level of soil freezing in the region.

- The parameters should allow the equipment to be installed in the caisson freely, with indents, so that the master can freely carry out maintenance and repair of the equipment.

- Manufacturing material. The most durable is a thick-walled polymer with stiffening ribs. Concrete and brick are in second place in terms of practicality, since they are capable of absorbing water, albeit slowly, but still. This can be avoided by applying external and internal sealing compounds. Metal is the worst option for a caisson. The material oxidizes and rusts over time. Even the use of protective anti-corrosion coatings does not help. Gradually, the composition in places recedes from the metal surface, and the box rusts.

For complete tightness, an upper hatch is provided in the caisson chamber. For a convenient descent down - a ladder.

Installation from various materials

To install a protective chamber for a well, earthwork is first carried out. A pit is dug around the casing to a depth below freezing of the soil. The width and length of the pit corresponds to the parameters of the intended tank plus 20 cm on each side for backfilling.

The bottom of the pit is carefully rammed and a layer of moistened sand is poured. It also compresses well. Then the concrete is poured, which serves as a rigid base for the tank.

Experts assure that it is not necessary to pour concrete mortar under a light polymer structure, but a site is needed.A caisson can be anchored to it, which is especially important for heaving soil or if there is a high ground level in the area. A site is required for reinforced concrete or brick tanks.

Installation of a polymer caisson

Installation of the caisson for the well is performed in the following sequence:

- In the bottom of the plastic reservoir, cut a hole equal to the diameter of the casing with a hacksaw.

- The caisson is put on the pipe and lowered to the very bottom, on a concrete platform.

- The tank is anchored with anchor bolts. It is advisable to lay under them tight rubber gaskets, smeared with sealant.

- Here it is worth sealing the junction of the chamber with the casing.

- On the sides of the caisson, holes are made for the outlet of the pipeline. The gaps between the walls of the chamber and tubes are also well worked out with a sealant.

- Backfilling of the reservoir is performed simply with soil. But for greater strength, experts recommend using a cement-sand mixture. It is slightly moistened and then tamped in layers.

The hatch of any caisson should rise 15-20 cm above ground level. This prevents rainwater from entering the chamber from above.

Installation of a metal well

When equipping a metal caisson for a well, the work is performed as follows:

- A box of the required parameters with a hinged hatch is welded from stainless steel or metal.

- On the sides, at a given height, threaded bushings are welded to output the pipeline.

- A hole is made in the bottom of the chamber along the cross-section of the casing.

- The box is treated from the inside and outside with protective anti-corrosion agents. Two or three layers of coating are applied to the welded seams.

- A metal caisson is installed according to the polymer principle. But here you will have to use special equipment. Since the mass of the box is large enough.

- The assembled chamber is anchored and then backfilled with pre-drawn pipeline lines.

When backfilling, it is worth taking care of the tank insulation, since the metal has good thermal conductivity. As a protective layer, you can use plates of expanded polystyrene, basalt, expanded clay. It is important to close the insulation layer from the outside with rolls of roofing material or coat it with bitumen mastic.

Reinforced concrete caisson

This is the most time consuming variant of the protective chamber device due to the mass of the rings. It is imperative to hire special equipment for their installation. The installation of the caisson is performed as follows:

- The first ring is lowered onto a pre-prepared concrete base.

- The second item is loaded. The joints are worked out with bitumen mastic. This also applies to the adhesion zone of the first reinforced concrete ring with a concrete platform.

- With the help of a perforator with a special crown, side holes are formed for the outlet of pipes. They are reinforced with stainless steel sleeves.

- Outside, the caisson of rings is coated with several layers of bitumen mastic to completely seal the chamber.

- It is important to take care of the insulation of the tank. It is wrapped on the outside with mineral or basalt wool, foam shells. A sealing layer is applied on top.

- Backfilling of the caisson is performed after the pipeline is withdrawn. Each layer of soil is rammed in stages.

The reinforced concrete structure is heavy. Therefore, when one ring is displaced, it will no longer be possible to correct the deformation. We'll have to dismantle the camera and install a new one.

Monolithic caisson device

This camera option also has its pros and cons. The main advantages are strength, solidity, durability. Of the minuses - high thermal conductivity, laboriousness of the process, the risk of depressurization of the chamber in very heaving soils.

Work according to the instructions is performed as follows:

- Formwork is mounted on the flooded and completely dried bottom. It can be installed from wooden boards at once to the full height or from wooden boards for filling the caisson in stages.

- In a concrete mixer, a solution is prepared from cement, sand and crushed stone.The proportions are 1: 3: 6, respectively. The mass should have the consistency of thick sour cream.

- A metal reinforcing mesh is inserted into the formwork and the walls are filled.

- It takes 3-5 days to dry the solution. In this case, the pit must be covered with a tarpaulin from the direct sun, and the concrete should be periodically wetted.

- After the solution has completely dried, the formwork is removed, and the walls of the caisson are coated on both sides with a sealant (bitumen mastic).

- With the help of a perforator and crowns, technical side holes are made. They are reinforced with sleeves.

- The gaps after the withdrawal of the pipeline are closed with mastic.

It is important to take care of high-quality insulation of a monolithic tank. It is made from deformation-resistant plate materials. The best option is extruded polystyrene foam. It is also advisable to insulate the camera lid.

After installation, the insulation is coated with another layer of mastic.

The top of the monolithic caisson is a concrete slab with a hatch hole.

Brick caisson device

This option is the most convenient, practical and budgetary, provided that there are blocks from building a house or after dismantling old structures on a private plot. You can expel the walls of the chamber with your own hands without the involvement of specialists. The number of blocks required is calculated according to the height and width of the walls. First, the estimated height of the caisson is divided by the height of one brick in cm. The number of rows for one side of the tank is obtained. Then the width of the wall is divided by the width of one block and the amount of material per row is obtained.

It remains to multiply the two resulting numbers with each other (this is the sum of the blocks on one side of the caisson). The total is multiplied by 4 (the number of tank walls).

- The installation of a brick caisson is carried out from the corners in the usual way. The thickness of the masonry joint is about 1 cm.

- After distillation, the chamber is well dried.

- Technical clearances are provided even when laying bricks, so that later you do not work with a perforator.

- The finished caisson is coated with bituminous mastic from the outside and from the inside.

The top cover can be made of a concrete slab or a strong wooden board covered with roofing felt.

The price of a professional caisson device

If you don't want to bother with installing the camera with your own hands, you can hire professionals. They complete the work in 1-2 days on a turnkey basis. At the same time, the price of installing a caisson per well varies depending on the following parameters:

- camera dimensions;

- caisson material;

- the complexity of land work;

- additional services (pipeline laying, etc.).

On average, in Moscow, the cost of such services is from 50,000 rubles.

To save family money, you can independently and correctly make your own well for installing downhole equipment.