Steel pipes are superior in strength, temperature and pressure resistance to similar products made of other materials. The application of an anti-corrosion layer prolongs the life of galvanized water pipes.

Regulatory Requirements

Galvanized pipes are used for supplying communications, technological systems with cold and hot water, steam, gas in aggressive environments. A metal water pipe quickly rusts when exposed to water and oxygen dissolved in it. The outer parts of the system corrode when exposed to humid air and condensation.

The VGP pipe is made of black steel in accordance with GOST 3262-75. The finished product is galvanized, which increases the service life of water supply systems. A zinc layer, at least 30 microns thick, protects the inner and outer surfaces of the steel from moisture and atmospheric oxygen. This increases the weight of the pipe by 3%.

The state standard regulates the following requirements for the production of galvanized pipes:

- products are made of steel tape by applying an electric-welded longitudinal seam with a tightness test;

- conditional passage - DN, is approximately equal to the inner diameter and corresponds to the size of the connected section;

- the curvature of the pipe is not more than 2 mm per running meter at DN 20 and 1.5 mm for large diameters;

- the length of straight segments varies from 4 to 12 meters;

- products are manufactured with threaded or rolled threads;

- the absence of a protective layer on the thread and ends of the segments is allowed;

- working pressure in accordance with GOST from 25 to 32 kgf / cm2, depending on the type.

The operating standards for cold water supply are 30 years, hot water - 20, while ordinary steel pipes serve, respectively, 15 and 10 years. In 90% of cases, the weld is the cause of leakage in the smooth section of the pipe.

Types and technical characteristics

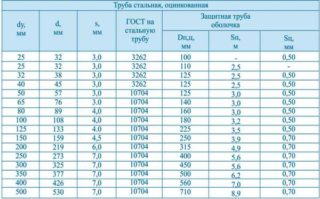

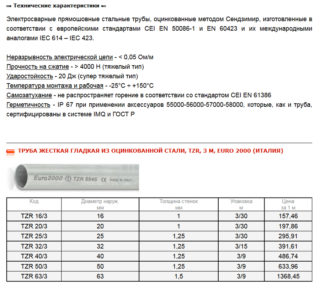

Depending on the area of application, the pipes are water and gas, electrowelded and profile. A galvanized pipe for water supply in accordance with GOST can have standard and increased manufacturing accuracy.

The assortment of products is distinguished by the nominal bore, outer section, wall thickness and weight. According to the nominal size, the size ranges from 6 to 150 mm, and the outer section can be 10.2–165 mm.

Depending on the thickness of the walls, the products are divided into light, ordinary and reinforced. For all types of remote control is the same. The inner diameter depends on the wall thickness. In light products, it is greatest, in reinforced products, it is minimal. The thicker the walls, the higher the rust protection.

The corrosive process is accelerated during periodic outages of water supply, when water is discharged, and raw air takes its place.

Pipe selection criteria

For consumers, throughput and operating pressure are important. The lower the pressure in the system, the larger the nominal passage must be. For an internal domestic water supply system, a pipe with a cross section of 20 mm is sufficient.

The dimensions of the walls are selected depending on the technological requirements of the lines to be laid. In this case, it is taken into account that ordinary and light bends are designed for an operating pressure of 25 kgf / cm2, and reinforced ones up to 32 kgf / cm2.

Galvanized products are 50-60% more expensive than conventional pipes. Pricing is formed based on the steel grade, assortment, product quality, manufacturer. The price per meter of galvanized pipes for a water supply system with a DN 15 mm and a wall thickness of 2.8 mm starts from 70 rubles.

The cost varies depending on the region of sale. The retail price is higher than the wholesale price. A ton of rolled metal can roughly cost from 48,791 rubles. Assuming that the weight of 1 p / meter of a galvanized ordinary VGP 15x2.8 pipe is 1.28 kg, 781 linear meters of pipe per ton.

Before purchasing, you must familiarize yourself with the certificate of conformity and the technical characteristics of the products.

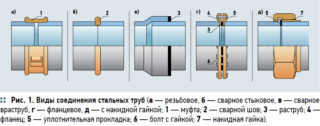

Connection and installation methods

The welding method is used to assemble all types of round pipes. Gas or electric arc welding is used. For the latter, it is preferable to use rutile-coated electrodes. The main difficulty is to prevent burnout of the protective layer. For this, the joint is covered with a welding flux. In this case, the zinc melts, but does not burn. Residues of the substance are washed out with a stream of water.

Mounting by means of a threaded joint requires an exact fit of the branch pipes and squeegees. Elbows are pre-prepared by cutting the pipes to the desired size. The edges are filed. Making threads by hand is a laborious process and requires special tools. The work is simplified if you use a lathe. It is better to paint over the thread, otherwise it will quickly rust.

Tubular products with factory-applied threads at the ends, after diffusion galvanizing, are ready for threaded connection. Installation is carried out using galvanized parts - these are couplings, nipples, reductions, corners, plugs. The joints are sealed with tow with paint. It can be replaced with fum tape or thread sealant.

The docking made in accordance with all the rules is airtight and safe, resistant to corrosion. Such a connection can be easily dismantled during repair or for subsequent replacement.

Advantages and disadvantages

- strength and fire resistance;

- does not overgrow with mineral deposits and rust;

- a low coefficient of thermal expansion is important if the pipe is recessed into a screed;

- the ability to install and repair yourself;

- use as a heat exchanger.

With an uninterrupted supply in the cold water supply system, drinking water is safe for humans. The maximum permissible concentration of zinc is not higher than 5 mg / liter, while the permissible daily rate for the body is 10-15 mg.

Zinc is a toxic metal. Accumulating in the body, it can cause serious poisoning. Using galvanized pipes for arranging a water main, you need to think about safety, use proven and high-quality materials.

The disadvantage is the high specific gravity and electrical conductivity. High heat transfer requires insulation of pipes in heating and hot water systems.

Temperature fluctuations in hot water supply reduce the anti-corrosion properties. At 60 ° –80 °, zinc reverses polarity. A cathodic porous coating is formed, and pitting corrosion occurs. The service life of such a pipe is reduced. For hot water supply and heating, products are used that have only an outer protective coating.

The service life of water pipelines with galvanized pipes depends on the quality and chemical parameters of the water. They are not used when installing wells. Lack of water exchange promotes chemical reactions that degrade water quality.