After equipping the well for water, it must be protected from external influences. Precipitation, groundwater and debris will spoil the quality of the source and speed up the cleaning period. Installation of a head is the best option for sealing the casing. A plastic or metal construction isolates the well, serves as an attachment point for the pump. The model is selected according to the diameter of the casing.

Definition and purpose of the well head

An autonomous source of water supply needs arrangement. The borehole head (OS) is a round-shaped structure that is put on the casing pipe. The part is made of durable materials that are resistant to climatic and mechanical stress. The head has several functions:

- isolates the mine from the ingress of melt water and precipitation;

- prevents debris from entering;

- the structure is used for hanging the pump;

- the cover reduces the risk of equipment theft;

- protects the source from freezing in winter.

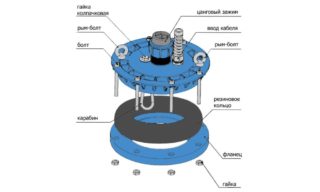

The head is an assembly of two flanges connected by screws. A rubber ring is located between them, which is a seal. The upper part is equipped with a carabiner for hanging the submersible pump. The cover has a hole for the power cable. In the middle of the upper flange there is a pipe connection.

After the head is installed on the well, the pump installation is simplified. It does not require the manufacture of a frame for its fastening.

Types and device

Factory heads from different manufacturers have similar designs. They are distinguished by the material. Products are of three types:

- Cast iron - the most durable and durable option. The robust design allows you to suspend equipment weighing up to 500 kg. The product consists of a cover, a pressure flange, an O-ring and hardware.

- Steel - in terms of reliability and withstand load, the nodes are not inferior to cast-iron models. An important factor is the anti-corrosion coating. The service life depends on its quality. Products are of high cost.

- Plastic - structures are designed to hold units weighing up to 200 kg. This option is recommended for mines with a depth of about 50 m. The products are resistant to corrosion, but cheap models may not withstand the winter cold. Care should be taken when tightening the fastening screws so that the material does not crack from pressure.

Some design features have received covers for wells with an adapter. They are made from cast iron. There is no hole for the water pipe in the upper part. The universal cover is suitable for multiple casing diameters (125,127,133 mm). It has openings for an electric cable and a safety cable.

Design features:

- Cover - the upper part of the unit, on which there is an opening for a pressure pipe, a cable entry, eyebolts for lifting the pumping equipment. On the inside there is an eyebolt for the cable. Mounting bolts are inserted around the perimeter.

- A flange is a round part with a cut out center. Slips over the casing. Fastens with a lid.

- Seal - the element is made of rubber. Its function is to ensure the tightness of the structure.

There are simplified versions of leaky heads. Craftsmen make protective knots on their own. For this, steel or aluminum is used.Flanges of the required diameter are cut from the metal. Holes are made in them for fasteners, an electric wire, a pipe.

Varieties of heads:

- Inner - The bottom flange and O-ring are placed inside the casing head. The structure rests on the top flange shelf. The cover has an inlet for a power cable and an adapter for a pressure line.

- Outer - the flange is put on the outer surface of the pipe after the pump has been released. A rubber ring is dropped from above. The upper part is secured with set bolts.

Installation of borehole heads facilitates pump maintenance. It can be easily lifted together with the cover by attaching the winch cable to the eyebolts.

Criterias of choice

When choosing a device in specialized stores, you must focus on the diameter of the casing. The parameters of the discharge pipeline are also important. The dimensions of the pipes are indicated in the product labeling. Basic designations:

- OS - borehole head made of metal;

- P - body material plastic;

- A - vandal-proof design;

- the first number is the casing diameter;

- the number after the slant is the diameter of the pressure hose or pipe.

Some models are versatile. Allowable casing sizes are indicated with a dash. The tightness of the structure is regulated by a rubber ring.

Before purchasing a headrest, the weight of the pump and accessories should be estimated. The safety rope, cable, hoses and the unit itself for deep wells are heavy. In such a situation, the use of plastic models is not allowed. Experts recommend choosing the material for the head the same as for the casing.

Installation features

The installation of an industrial head can be done by hand. It does not require the acquisition of special tools and skills. The work is divided into several stages.

Preparatory stage

- A straight cut of the casing is made. It is deburred and sanded. This will give maximum tightness. Rust is removed from the metal, it is covered with a primer and anti-corrosion paint.

- The pump is being prepared for running down the well. The required length of the safety cable is measured. The recommended product material is stainless steel or nylon. The power cable is connected to the cable with plastic clamps. The end of the wire is led out into the hole in the cover. The cable gland is equipped with a spring guide or a collet for adjusting the sliding speed. It is loosened during installation.

Head mounting

- The bottom flange is slid over the casing. A rubber seal is dropped on top of it. If the ring does not move well, the area is covered with grease.

- The safety cable is attached to a special eyelet on the pump, the other end to the cover carabiner. Depending on the weight of the unit, several people lower it or use a winch. The dive is slow, without jerking or swaying.

- The upper part of the head is put on the discharge pipe or hose, the fastener is tightened.

- The rubber ring and bottom flange slide towards the top. The bolts line up with the holes and are tightened with nuts. So that the construction of the village is uniform, the fastening takes place according to a certain pattern. The bolts are tightened gradually, opposite each other. Fastening occurs until complete fixation.

- The final procedure is to securely fasten the electrical wire. Tighten the input nut to the end.

When tightening the bolts, the forces must be calculated, otherwise the rubber ring will burst. The tightness of the structure will be broken.

In winter, metal models can freeze, so the design requires insulation. A heat-insulating box is installed around it. A good option is a caisson device. It is a small chamber below ground level that houses the pumping equipment. Its walls are insulated with foam.

Manufacturers and cost

The price of the device depends on the size, material and manufacturer.Popular manufacturers of downhole components:

- Dzhileks - a Russian manufacturer of pumping equipment offers models with OSB, OSB, OSPB marking (plastic with a base part in the form of a built-in terminal box). The models are easy to install and operate, suitable for use in summer cottages and private cottages. The price of products is 2000-4000 rubles.

- Aquarius - products are designed for casing diameter 90-168 mm. They are suitable for various materials - PVC-U, HDPE, steel. The plastic version assumes installation of a pump with a weight of up to 200 kg. Models are recommended for shallow penetrations. Their plus is the affordable cost of the order of 1500-3000 rubles.

- Merrill - the heads of the American company are available in two body materials - plastic and cast iron. Installation requires the installation of a ventilation inlet valve, otherwise the device is ready for use. The valve is purchased separately. Manufacturer's warranty for 10 years. The cost is from 2400 to 4200 rubles.

The use of caps is the most affordable option for protecting an autonomous source. Installation does not require welding. To secure, just tighten the fixing screws.