High-quality water purification is a guarantee of good health and excellent well-being. At the same time, various methods can be used for water treatment. Sand filters are used as mechanical filters for water purification. They rid the liquid of various suspensions and harmful impurities. The filter is based on quartz sand. It is the most readily available natural mineral on the planet.

Application area of quartz sand for water purification

Quartz sand is used to filter water in the following areas:

- utility companies engaged in the preparation of liquid for delivery to subscribers (Vodokanal, etc.);

- purification of the aquatic environment in aquariums;

- filtration of liquid in swimming pools;

- local treatment plants for effluent clarification;

- private property, autonomous well or borehole water supply.

Quartz-based filters are widely used in industrial fields - mechanical engineering, petrochemical processes, energy.

Quartz properties for water purification

Sand has a number of positive properties:

- has a detrimental effect on parasites;

- reduces the concentration of radionuclides in the treated environment;

- completely removes chlorine, iron, manganese, aluminum from water;

- collects heavy metal ions by adsorption;

- inhibits bacteria and viruses.

Quartz sand has good porosity. From this, the dirt present in the liquid is maximally deposited in the quartz mass. In addition, the bulk material is resistant to any mechanical stress.

Classification and standardization of quartz sand

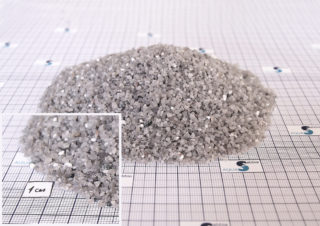

Quartz natural sand is mined in places of mineral deposits. The resulting material is thoroughly washed and then enriched electrochemically. Artificial quartz is obtained by crushing stone blocks. It is called crushed. The finished raw material is sieved to sort the material according to the size of the grain size fraction.

At the place of extraction of quartz bulk material, the following are distinguished:

- mountain;

- river;

- dune;

- cellar.

Quartz filler for filtering installations and systems must comply with GOST R51641-2000. The latter regulates the standards and requirements for cleaning mineral additives. Rounded and crushed sands fully comply with the established standards. The first is the most durable, pre-calcined in ovens at high temperatures. Crushed - the most porous, with a large number of microcracks.

Criterias of choice

When choosing sand filters for water treatment with quartz, you should pay attention to the following parameters:

- Granule size (fractionation). It is recommended to take material with particles up to 0.8 mm. In this case, it is important to familiarize yourself with the technical characteristics of the filter itself and take the sand that is recommended for a particular model. It's okay if the faction is slightly smaller or larger. But you need to be prepared for the fact that too small particles will flow out of the filter along with water, and very large ones will poorly clean it.

- The presence and amount of impurities. Good quartz complies with GOST and does not emit harmful substances into the liquid. Such data are indicated on the packaging for the material.

- Color and density. As a rule, quality sand has a milky white hue. Its bulk density is uniform.

Purchased quartz is placed in special polymer or metal filters.

Before the first use of the mineral additive as a cleaning agent, it should be rinsed from accumulated dust.

Water purification mechanism

- sand;

- diatomaceous;

- cartridge.

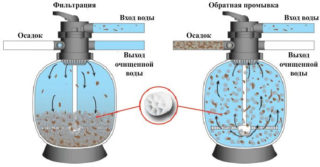

The principle of liquid processing is that water is driven through the sand layers using a special pump several times (5-6) per day. In this case, at first all impurities settle on the surface of the free-flowing layer, and then suspended particles remain in its thickness.

To increase the throughput of the filter, it is advisable to use special metering pumps. The quality of water purification directly depends on the size of the grains of sand. The smaller they are, the better the water treatment is.

The quartz filters should be changed regularly to prevent over-contamination.

Disadvantages and advantages of quartz sand water purification

The main advantages of using quartz as a treatment system are as follows:

- An excellent indicator of the uniformity of grains of sand. Reaches 98%.

- Explicit fraction size equal to 97% of the total.

- High porosity of the crushed material, which increases its filtration capacity.

- Large surface area, due to which a high flow rate of water volume through the sand filler is achieved.

- Excellent dirt holding capacity of quartz bulk material. A large amount of suspensions present in the liquid settles in its thickness.

- The ability to use crushed material as a support layer for multi-stage filters.

- A large selection of types of quartz sand in terms of fraction size and even color.

The real disadvantages of quartz include:

- The presence of dust or a small amount of clay in the bulk material, which must first be removed by washing. Only then can the sand layer be used as a filter. Water, which will be pre-washed with bulk material, cannot be discharged into the sewer. It should be collected in a separate tank and defended. The settled dust particles are disposed of as solid waste after the upper settled water is drained off.

- Freezing of free-flowing quartz under the condition of natural moisture. Sand can also freeze if the filter is left in the outdoor pool for the winter.

- The need for frequent replacement of the filtering quartz layer. It needs to be renewed as soon as the water has a characteristic stale smell and possible impurities.

- High cost of bulk material.

People who once tried quartz as a home water filter have appreciated its effectiveness. In the presence of sand, there is no need to install complex filter systems.