A hydraulic accumulator in a water supply system can be called not only a liquid accumulator, but also a protective element, since one of its functions is to smooth out water hammer. In the pump operating instructions there is a technical parameter - the number of on and off cycles or the permissible frequency. By using a hydraulic tank, you can extend the life of your equipment and reduce repair costs.

- Purpose of the accumulator in the water supply system

- Varieties of devices

- Membrane HA

- Balloon GA

- Horizontal and vertical models

- Place of the container in the water supply system

- When the hydraulic tank is not needed

- Connection methods and diagrams

- Subsurface pump connection

- Connection to surface pump or pumping station

- Scheme with two hydraulic tanks

- Connection to the water heating element of the system

- Pressure switch settings

- Hydraulic accumulator care

Purpose of the accumulator in the water supply system

A hydroaccumulator is a metal container for storing a supply of water. If the system did not have this important element, the pump would have to turn on every time when the tap was turned on in the house, the washing machine turned on, or people used the shower. Due to the liquid reserve, the pump turns on less often and saves a resource.

GA have a different volume. It depends on the pressure setting and the size of the storage tank. On average, a one-liter container in working order can hold 30 - 35 liters of liquid. This data is needed to determine how much water needs to be stored for a family of 2, 3 or 4 people. The lower the pressure, the more water will fit inside. With an increase in indicators, the volume of liquid decreases.

Installing a hydraulic accumulator for do-it-yourself water supply systems is not particularly difficult. A beginner can do this by first reading the manual or watching a video showing the process in practice.

Varieties of devices

Distinguish GA by location. Large containers are usually placed in the attic of a private house or above the distribution unit so that the force of gravity acts on the liquid, and it flows by gravity into the pipe. There are models of accumulators that can be installed anywhere in the system, even below the water intake level. The process of liquid entering the house is controlled by sensors and does not depend on gravity. The ancient analogue of the tank is the water tower.

One of the types of GA does not provide for the presence of anything inside the tank except water and air. The amount of air mixture must be constantly monitored. This is not very convenient, so manufacturers produce membrane or balloon models.

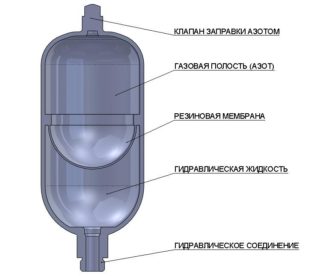

Membrane HA

There is a rubber membrane inside the accumulator. On one side there is a liquid, on the other - an air mixture. The flow of water inside occurs up to a certain point, it depends on the pressure settings. As the water compartment fills, the air is compressed. As soon as the pressure reaches a critical level, the sensor is triggered and the pump turns off. When the tap is opened, fluid from the hydraulic tank is consumed first. When the pressure drops, the lower setting is triggered and the equipment starts up again.

A distinction should be made between red and blue tanks. The first ones are designed for closed heating systems and are designed for lower pressure. The rubber inside is technical and is not intended for storing drinking water.In blue HA, the membrane is made of food grade rubber.

Balloon GA

Balloon models have a rubber container inside, the neck of which is hermetically connected to the inlet pipe. The liquid entering the inside does not come into contact with the walls of the container, but is completely contained in the rubber bag. The second half of the tank is filled with compressed air. Further, the principle of operation of the bladder accumulator repeats the membrane method of adjusting the pump on and off. Tanks with a volume of more than 100 liters have a special valve through which you can periodically bleed the air mixture.

Horizontal and vertical models

Horizontal and vertical design of accumulators exists only for convenience of use. If the container will be installed in a small bathroom, it is better to buy a vertical model that will take place up to the ceiling. There are special mounts that allow you to mount it to the wall. Horizontal models are more stable, but require more space. They are usually placed in basements or technical rooms. They have legs and holes for fixing in the floor.

Place of the container in the water supply system

In water supply systems, the accumulator is located after the pump, in front of the inlet pipe. At this point, he is able to control pressure and perform protective functions, for example, in case of a water hammer. Water hammer occurs when the crane is suddenly closed and the pump is running at the same time. The liquid moves by inertia to the outlet, when it is blocked from movement, a backward wave occurs. It collides with the incoming mass of liquid and the pipes are damaged. The absence of a counter flow prevents the line from bursting.

Some buyers confuse a storage tank with an expansion tank. The second is designed to compensate for liquid losses during heating and is installed in heating systems. When the liquid evaporates, an additional portion comes from the water supply.

In the event of a power outage, there is a small supply of water that can be used for domestic needs.

In addition to the protective and storage function, the GA serves to maintain a constant water pressure in the system. It may decrease slightly when the tank runs out of liquid and the pump is about to turn on.

When the hydraulic tank is not needed

In irrigation systems, a hydraulic accumulator is not needed, since with a constant open tap, the pump will work without shutting down. If there is a storage capacity in this scheme, the equipment will often turn on, which will lead to premature depletion of the resource.

When buying a pump with an automatic system that assumes a smooth engine start, a GA is also not needed. Water hammer does not threaten the pipes, since the fluid flow moves slowly.

Connection methods and diagrams

The scheme for connecting a borehole pump to a hydraulic accumulator will depend on the purpose of the equipment itself:

- When arranging a cold water supply system, the storage tank is installed in a certain place, and the pressure sensors are connected using a fitting for 5 inputs. To prevent pump vibrations from affecting the accumulator, it is connected with a flexible hose. Such a system will need to be periodically inspected, before draining the water through a tap or a nearby pipe cut into the mains.

- In an apartment building with a centralized water intake, the HA is mounted in front of the pump, that is, the container is filled from the central pipe and transported to consumers with the help of a pump. In this case, the GA compensates for the low pressure of the central line.

- If the system has a boiler, the accumulator is connected to it.

These are the simplest schemes that allow you to quickly establish water supply.

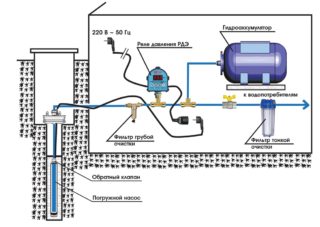

Subsurface pump connection

The technical characteristics of the well do not always allow installing a powerful submersible pump in it. For example, if the casing is too narrow and the hole is deep.In such a situation, it is necessary to select a deep unit, the power of which is sufficient to lift the liquid from the depth to the storage tank. It can be located in a caisson or on the surface of the earth close to the well.

Further, near the accumulator, another pump is mounted - a self-priming one, which will transport water to the house. Another accumulator is installed in the room, which regulates the pressure in the system and controls the operation of the second pump.

The second container should be membrane or balloon. So that the liquid does not stagnate in the first container, its volume should not be very large. It is possible to connect the accumulator directly to the submersible pump only if the parameters of the well and the power of the electrical equipment are in full compliance.

Connection to surface pump or pumping station

At surface pumping stations, a hydraulic accumulator is included in the kit, so it is recommended to install an additional tank if you need to protect the equipment from frequent switching on or have a large supply of water for any reason. GA is mounted after the station.

A surface centrifugal pump, which does not have a storage tank, can be connected using a 5-outlet fitting:

- The fitting is connected to the container using a flexible hose.

- A pressure gauge and relay are mounted.

- The contacts of the pressure gauge, the relay with the pump and the network are connected.

- The pump is connected.

When sealing joints, it is better to use tow, since the FUM tape deteriorates quickly. After checking the diagram of a pumping station with a hydraulic accumulator, you can test the system.

Scheme with two hydraulic tanks

If there are new household appliances in the house that consume liquid, it makes sense to add a few more hydraulic tanks to the system. There can be 2 or more of them. The more, the less often the pump turns on and the longer the engine wears out.

All accumulators are connected in parallel. The advantage is that if one of them breaks, all the others will do their job. Installation of additional relays and pressure gauges is not needed - they are on the first tank.

How to connect the second and subsequent hydraulic tanks:

- a tee is installed at the entrance to the first;

- a pump is connected to one outlet;

- to the second - the next capacity.

For convenience, you can use metal-plastic pipes so that the containers can be placed side by side if there are more than two of them. There is no need to change the relay settings.

Connection to the water heating element of the system

When the water is heated in the boiler, the pressure rises. In a closed system, this can lead to accidents and injuries. To reduce excess pressure, a hydraulic accumulator is installed as an expansion tank.

Excess hot liquid will be poured into the HA, and then consumed for domestic needs. Hydraulic accumulators are used, the membrane of which is designed for hot liquids.

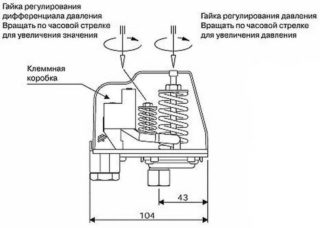

Pressure switch settings

Before starting the system, the pressure switch must be set correctly. The operation of the entire system will depend on this.

Connection rules:

- the plumbing system must have its own power supply line;

- use a two-core copper cable;

- the wires must be grounded so that the current does not come into contact with water.

How to set up a pressure switch:

- Switch on the system.

- Based on the readings of the pressure gauge, use a wrench to set the lower pressure limit, twisting the large spring.

- Adjust the upper limit with the small spring.

- Check how the system works. If the pump does not turn on or does not turn off according to the settings, repeat the cycle from the beginning.

For convenience, the difference between the lower and upper thresholds should not exceed 1 bar. In the case of low pressure, the diaphragm will stretch strongly, which can lead to rupture. A small difference between the two will lead to frequent activation.

With large-capacity accumulators, you can set the difference between the upper and lower pressure of 2 or 3 atmospheres.

It is better to invite an electrician to select the wires so as not to damage the equipment.

Hydraulic accumulator care

To extend the life of a GA, the following rules must be followed:

- monitor for leaks - they can occur due to poor tightness or vibrations transmitted from the pump;

- check the air pressure inside - its drop can cause the rubber to burst and fluid from the air valve;

- immediately respond to malfunctions in the system, since the problem may lie not only in the pump or GA.

In order to detect the problem in time, experts recommend checking the parts for wear every six months. To do this, disconnect the hydraulic tank from the system, drain the liquid and remove the ring holding the membrane - in this place, rubber tears most often occur, after which air begins to flow into it. Replacing the pear is not difficult, it is important that it is matched in the same way as the first one and conforms to the technical characteristics.