On shallow wells and in Abyssinian wells - "needles" pressure equipment is used, which is installed on the surface. The operating time of the water supply system and the efficiency of the water intake depend on how correctly the pumping station is connected.

The principle of operation of pressure equipment

The station installed on the surface is designed to supply liquid from sources at a shallow depth: up to 8-9 meters. Pressure equipment does not need to be immersed in water.

The surface pump works according to the following principle:

- The expansion tank or hydraulic accumulator connected to the pump is filled with water to the set level due to the design.

- Automation turns off the pump after the liquid reaches a certain level. The water intake is stopped.

- When the liquid level in the storage tank drops, the automation turns on the pump, and it fills the hydraulic accumulator.

The principle of operation is based on the fact that a vacuum is created in the part of the suction hose that is not immersed in the liquid. Water rises through the conduit due to the difference in pressure indicators between its ends.

Installation of the installation itself is not difficult. To do this, you just need to carefully study the attached manual and connect the parts with each other. The installation scheme in the right place and connection to the well is more complicated.

Pump selection and installation location

- Performance. For watering the garden, a pump with an efficiency of about a cube per hour is quite enough, but for the water supply system of the house, calculations will need to be made, taking into account the number of people living in it and the number of water intake points. A family of four needs to purchase a pump with an indicator of at least three cubic meters per hour.

- Depth of water supply. The length of the pipes, their location vertically or horizontally, the size of the water supply source are taken into account.

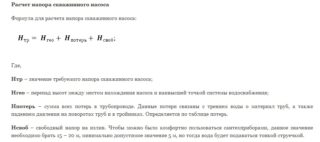

- The head of the water flow at the very last point of the water intake, located as far as possible from the pump. The value must be large enough. The pressure indicator, as a rule, is indicated in the accompanying documentation for the equipment and is measured in atmospheres, bar. You can find the value by summing up all the distance segments that the liquid will pass. Every 10 m, there is a decrease by one atmosphere.

- Voltage in the electrical network. This indicator is also of great importance, since it affects the performance of the pumping station. If the voltage drops, the pump simply does not have enough power to provide the entire house with the required volume of water.

A surface pump, in addition to water supply for a cottage, can also be used to water a vegetable garden, a garden or to pump water from a basement, which is important for areas where spring flooding often occurs. To equip an autonomous water supply system, you need to purchase a pump with a higher power than for conventional greenhouse irrigation.

Installation of surface pumps is always carried out on land, since moisture is not allowed to enter the device case. Ideally, the electric pump should be located as close as possible to the water supply source. Installation in a room with a high concentration of moisture, low temperature, poor ventilation and open to atmospheric manifestations is prohibited.

There should be enough space not only for the pumping station, but also for adjustment, maintenance, repair work. Installation of pressure equipment in the basement is allowed, but constant noise cannot be avoided.

To mount the unit, small buildings are erected next to the well, or caissons are installed in the ground - insulated structures made of concrete, plastic, or metal. The installation of the latter is carried out below the freezing point of the earth.

If a large concrete ring sump is a water intake point, you can install the pump directly in it. There is no need for excavation work, a strong raft of small size is required, but so that it can withstand the mass of the pump attached to it. The structure is lowered directly onto the water surface. The disadvantage of this method is that the pressure device will have to be removed periodically to adjust the pressure.

Installation steps

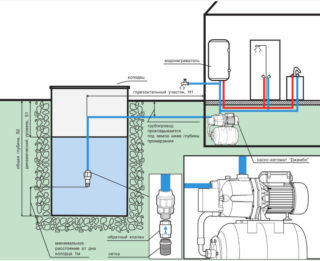

In order to correctly install a surface pump on a water supply well, in addition to the electric pump itself, a hydraulic accumulator, automation for starting and stopping, a pressure switch and a pressure gauge, as well as a mesh filter element and a non-return valve are required. You can choose additional elements yourself or purchase a complete unit. You also need fitting elements and pipe sections with a section of 32 or 25 mm for inlet and outlet.

Pipes are purchased in such a way that at least 30 cm of the lower part is under the water mirror. The total size should not be larger than indicated in the instructions for the unit.

At the place of installation of pressure equipment, it is necessary to build a reliable pedestal or fittings, to which the unit frame is rigidly fixed. It should have mounting holes or feet. To reduce vibration and noise, a rubber mat is placed under the device.

Installation of a surface pump on a well is carried out using the following technology:

- A piece of polyethylene pipe is cut off to the desired length.

- At one end of the pipe section, a brass or plastic coupling with an internal thread, a nipple and a non-return valve are installed.

- Additionally, the system is equipped with a mesh filter for coarse cleaning.

- On the opposite side, the pipe is equipped with a coupling and connected to the station input. Often there is an internal thread on the inputs, it is sealed with FUM tape or sanitary flax.

For ejector models, a recirculation hose must be installed.

Connectivity technology

Be sure to check the total length of the vertical and horizontal delivery pipe before connecting the surface pump to the source. It should not be larger than the size indicated in the accompanying documentation for the device.

The connection is carried out according to the following scheme:

- Connect the pump outlet to the water supply through the shut-off valves. You will also need a single elbow or tee, it depends on the number of wiring.

- Plug the plug into a 220 V / 50 Hz electrical outlet.

- Pour water into the special hole on the station body, which is located near the pump, in accordance with the manufacturer's recommendations.

- Perform a test start of the unit and wait until the automatic shutdown is triggered.

- Check the indicators in the hydraulic tank on the pressure gauge and check them with the data of the technical passport of the device. If the values do not match, adjust the pressure switch.

After filling the battery, you need to open the taps, check the pressure and the general functioning of the water supply and plumbing fixtures.

Despite the fact that the connection of surface pressure equipment has some difficulties, careful reading of the manufacturer's instructions, as well as the use of professional advice, will make this task possible even for a beginner.