To supply water to a house from a borehole or well source, pressure equipment is required. Submersible models are most often used, since they are easy to operate and unpretentious. For self-assembly of a water supply system, it is necessary to have an idea of the scheme and connection features of a submersible pump in order for it to function correctly.

How to connect a pump to a well and water supply

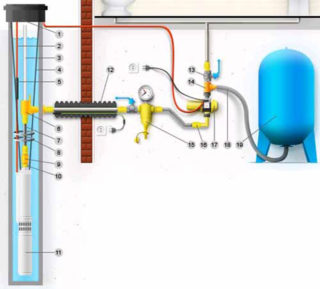

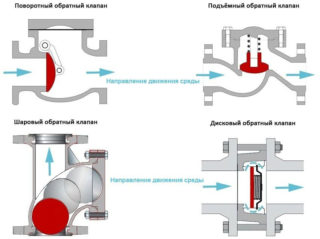

Thorough cleaning of the borehole is required before installing the submersible pump. For this purpose, using a temporary pump, liquid is pumped out of the column until all sand and impurities have been removed. To protect the pressure device from water hammer, a non-return valve must be installed on it.

The pump is connected to the well in the following sequence:

- The pipeline is being installed. When connecting the pump to a rigid pipe between it and the main line that transfers water to the consumer, it is better to insert a small piece of flexible hose to dampen the vibration of the electric motor.

- A cable, electric wire, hose are connected to the apparatus.

- The device is smoothly lowered into the well.

- When the pump reaches the bottom, it is raised by half a meter.

- The cable is rigidly fixed, the cable is connected to the mains, the hose is connected to the rest of the system and laid in the fixing channels.

A cover should be installed at the wellhead to prevent dirt and foreign objects from entering the well.

Electrical connection diagram

Depending on the needs of the user and his financial capabilities, you can choose one of the methods for connecting the deep pump to the electrical network.

Without automation

Without auxiliary control devices, the pump is connected using a pre-assembled electrical outlet with a ground contact. The pump is also grounded. For this, the main bus of the house is used, which is connected to the existing grounding contour of the building.

A three-wire cable is used to supply electricity to the outlet. The power supply voltage of the submersible pump is 220V. Do not use 380 or 150 volt sockets.

The connection method without automation cannot be considered correct. It only represents the general principle of connecting a pressure head device for a well. If you do not install the automation that controls the operation of the pumping equipment, it can break down during idle.

Through pressure switch

To reduce the cost of a set of pressure equipment, you can use a downhole pump connection diagram only with a pressure switch without a control unit. The device turns off the pump when the pressure reaches its maximum, and starts it when the indicators decrease to a minimum.

Using the control unit

When choosing an automation model, you first need to find out which protective system has already been supplied by the manufacturer in the pump. Modern devices are already protected from overheating and idling. Sometimes the equipment is equipped with a float mechanism. Taking into account these data, you can choose one of three automation options - simple, with a second or third generation electric control unit.

The simplest protection most often used for automatic water supply.The control unit is assembled here from three devices:

- Dry run blocker. It will turn off the device that runs without water, preventing overheating. Sometimes additional installation of a float switch is allowed. It performs the same functions, turns off the pumping equipment when the water level drops, preventing it from overheating. It may seem that the devices are primitive, but they provide effective protection for the electric motor.

- Hydraulic accumulator. Without it, it will not work to provide automatic water supply. The hydraulic tank works as a water accumulator. There is a working mechanism inside - a diaphragm.

- Pressure switch complete with pressure gauge. This device allows you to configure the operation of the relay contacts.

It is not difficult to equip pressure equipment with your own hands with simple automation. The principle of operation of the system is simple: when water is consumed, the pressure in the hydraulic tank decreases. When the minimum indicator is reached, the relay starts pressure equipment, which pumps water into the reservoir. When the pressure in the hydraulic accumulator reaches its maximum, the relay switches off the unit. In the process of consuming water, the cycle repeats.

The regulation of the pressure limits in the accumulator is carried out by means of a relay. In the device, using a pressure gauge, the minimum and maximum response parameters are set.

The downhole pump can only be started after checking and adjusting the pressure in the reservoir. The indicator should be equal to 0.9 of the value when turned on.

IN second generation automation the connection goes through an electrical unit with a set of sensors. They are mounted directly on pressure equipment, as well as inside the water supply network, and allow the system to function without a hydraulic tank. The impulse from the sensors goes to the electronic unit, which controls the system.

The operation of pressure equipment with the following scheme for connecting a submersible borehole pump to automation:

- Liquid accumulates only in the water supply system where one of the sensors is installed.

- When the pressure drops, the sensor sends a pulse to the control unit, which starts the pump.

- After reaching the desired pressure of the water flow in the water supply, the pump is turned off in a similar way.

To install such an automation, you need basic knowledge of electrical engineering. This and the previous protection work in almost the same way - in terms of water pressure. However, an electrical unit with sensors is more expensive at a cost, which is why it is not so popular among consumers. Even when using automation, you can not use the hydraulic tank, although in case of power outages with it, you will not be left without water. There is always a reserve in the drive.

Third generation automation reliable, high quality and expensive. Its installation allows you to significantly save on electricity due to the ultra-precise adjustment of the electric motor. The connection diagram of the advanced automation to a submersible pump for a well is very complex, so you should contact a professional to connect it. But it provides full protection of the motor from various breakdowns, for example, overheating during dry running or burnout of windings during voltage surges in the network.

The unit is powered by sensors without a hydraulic tank. Efficiency is achieved through fine tuning.

The electric motor of the deep pump, when starting, pumps the liquid at maximum power, which is not always necessary at a low flow rate. The improved machine starts the motor with the power required for the required intake volume and water flow. This contributes to saving electricity and extending the operation of pressure equipment.

Possible errors when connecting equipment

Breakdown of the pump cannot be avoided if the height of its suspension is incorrectly determined. If set too low, small stones or sand will enter the pump. If, on the contrary, it is too high, it can suck in air.Failure to install a non-return valve has a negative effect on the pressure device. In such a situation, at each start-up, it first fills the vertical pipe with water, and after it is turned off, a water hammer acts on it.

With an increase in the height of the water rise, the impact force increases, so the damage that is done to the pump will be greater.

Also, too small a cross-section of the water supply pipe is not recommended. The operating period will remain unchanged, but this will have a negative impact on performance. Uninstalled electrical protection, especially in areas with voltage surges, can damage the pump.

It is better to connect electrical devices through stabilizers, and complex and expensive electrical equipment through special control and protection stations. The cross-section of the electric wire must be sufficient, otherwise the operating time of the motor will be significantly reduced.

In case of improper installation of automation and instrumentation, as well as the connection of pressure equipment to the well, an accident in the system is inevitable. If you don't know much about the topic, it is better to entrust the work to professionals.