The best option for arranging a water supply system in a private house is a submersible pump with automation. The autonomous operation of the in-house system solves the problem of continuous water supply to all water supply units, regardless of the number of storeys and area. It is necessary to choose a submersible pump for a well or a well based on its technical characteristics, the depth of water intake, the height of its supply, having previously calculated the estimated volume of water consumption.

Scope and types of submersible pumps with automation

Submersible pumps with automatic control are used to provide water to a residential building, an irrigation system for a personal plot or to pump out waste, melt water, sewage in case of damage to the drainage system.

There are several types of pumps:

- Deep well with centrifugal operating principle for clean water. They are lowered into wells with a depth of 10 to 50 m and more. Cylindrical body made of stainless steel or metal with anti-corrosion coating. They have a high throughput. The operating time depends on the manufacturer and the operating conditions.

- Vibrating. They are installed in shallow wells and wells up to 10 m. Unlike centrifugal ones, they can pump water with a light suspension formed during operation. There is a nuance: vibrations contribute to soil subsidence around the casing. Periodic cleaning of the bottom funnel is required to prevent equipment damage.

- Drainage submersible pumps with pressure sensor. There are two types: centrifugal and vibratory. Designed for pumping water with impurities of rocks, large inclusions. The variety is fecal. In the bottom part there are filter holes that determine the size of the passed particles. They work effectively at a depth of up to 2 m.

A non-return valve is installed on centrifugal and vibration devices. It is mounted separately. Designed to prevent the return of water from the system to the well.

Types of automatic systems

The operation of submersible pumps with automatic activation is controlled by one of three types of equipment:

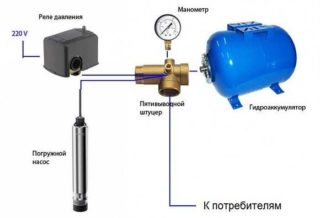

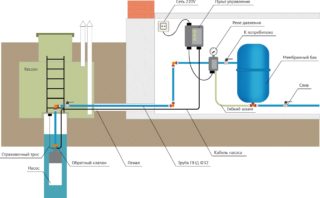

- Systems with a hydraulic accumulator. Built-in automation monitors the filling of the inner membrane. When the pressure drops, the relay is triggered and water intake starts. This is the simplest type of automatic control, regulated by a built-in manometer.

- Electronic relay device with a set of sensors on the pump body and on the walls of the pipeline. The sensor in the pipe, responding to a decrease in pressure, turns on the motor. With this type of automation, a hydraulic accumulator is not required.

- The work is controlled by an electronic device with high sensitivity sensors. Each system is customized according to individual customer requirements. Programmable automation also regulates the flow rate and the volume of liquid.

The choice of an automation system depends on the expected loads, cost and complexity of maintenance.

Criterias of choice

Equipment for the water supply system is chosen according to several important parameters:

- appointment;

- characteristics of water in the source.

- the performance of a submersible pump with automatic activation, which shows the amount of water passed per minute, hour;

- the height of the water column created by the pump;

- well depth;

- the height of the wiring of communications;

- length of the water supply network.

The nominal parameters indicated in the technical documentation differ from the actual ones. The manufacturer does not take into account the length of the network wiring. When calculating, it should be borne in mind that every 10 m of the horizontal corresponds to 1 m of the vertical column.

Installation features

Depending on the complexity of the installed automation, the installation can be performed independently or by contacting specialists. Systems with a hydraulic accumulator and a relay block are simple ones - they can be connected by hand according to the attached diagrams in the same way as a check valve.

For trouble-free operation of the programmable electronics, installation and service must be performed by qualified personnel.

Advantages and Disadvantages of Automatic Devices

Submersible pumps with automatic control of water supply differ in the principle of operation, power.

Centrifugal devices have a high safety factor. The cylindrical elongated shape allows them to be installed in casing pipes up to 20 cm in diameter. The powerful flow created inside the blades of the motor picks up fluid without having a destructive effect on the well. Installed permanently. The service life usually exceeds those indicated by the manufacturer. Filters must be cleaned regularly. Works in clean water. Turbidity can damage the motor.

For water intake from a well or shallow well, it is better to install vibration models such as "Grundfos". The best option for summer cottages, since their capacity is sufficient to provide a small household or watering the site. In comparison with centrifugal ones, they have a smaller working resource.