When building a private house, the laying of a water supply system is carried out at the stage of building the foundation. The use of modern materials simplifies the process, it can be done independently without involving professionals. Considering all the nuances, it is possible to mount a drainage system without high costs and as soon as possible.

Initial stage of work

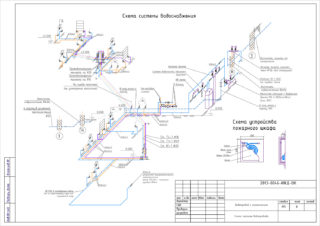

Before laying a water or sewer pipe underground, you need to make a project. It must be as accurate as possible, otherwise the pipeline system will not be functional.

In the project documentation, the presence of such information is mandatory:

- features of the old highway, if communications are being replaced;

- soil quality - light, clayey, stony;

- the area of the site where the pipeline will be, taking into account the branches and entrances;

- estimate of construction and repair work.

The laying of an external water supply system is carried out only on a leveled site. Otherwise, there may be problems with the water supply due to pipe deformation.

Technical standards for buried systems

The laying depth is indicated in special rules - SNiPs. All the nuances of working with products from a variety of materials are spelled out there. The minimum depth is one and a half meters. In general, this level depends on the depth of soil freezing. The pipeline should be deepened below the frozen ground level. In regions with a cold climate, the line will have to be buried deeper, otherwise it will deform under the influence of low temperatures.

The nuances of the correct laying of the water supply system are described in a special document: "State Elemental Estimated Standards for Construction Work" (HPES).

In the middle lane, it is necessary to lay water supply pipes 1.6 meters from the surface, then they will not freeze and bend in winter during severe frosts.

Suitable pipes for buried ground

Traditionally, welded steel or seamless steel products are used for these purposes, preferably with galvanized steel to protect against rust. However, now they have been pushed aside by polypropylene and plastic versions, for example, "PND PN10". They have many advantages:

- resistance to corrosion and temperature extremes;

- increased working pressure - up to ten atmospheres;

- ease of installation - polyethylene pipes are easy to bend.

An important plus is the budget price. This factor makes the cost of laying propylene pipes in the ground per linear meter lower than steel pipes.

The diameter of the pipe for laying in the ground according to GOST should not be less than 3.2 cm.The length of a standard product is 240 cm.

Underground water pipeline construction technology

Work on the laying of any water supply pipes is carried out in one of two ways: with or without digging a trench. The choice of the method depends on many factors: the presence of old communications, the composition of the subsiding soil, the location of the water-saturated layer. In order not to make mistakes when installing the highway with your own hands, it is worthwhile to first clarify all points with specialists.

Trench way

- A long ditch is being dug with a depth of one and a half meters or more, depending on the climate. Width - 50 cm.

- The walls and bottom of the track are compacted. Since the water will flow under pressure, unlike sewers, it is not necessary to make a slope.

- The shock-absorbing sand and gravel cushion is filled in by about 15 cm.

- The pipes are insulated, then they are laid on a pillow and articulated with fittings.

- The connecting nodes are covered with insulation.

- Outlets are connected to the ends of the line to connect to the pump, if the site is equipped with a well or to the central network, as well as to home wiring.

- The moat is covered with sand, and on top - with earth.

It is advisable not to concrete the surface of the site, but to lay tiles, so that in case of malfunctions, it would be possible to open the coating without problems and eliminate them. To bring the wiring into the house, you need a puncher. It can also be used to drill holes for hidden communications. In a wooden building, an electric drill and a jigsaw are used for these purposes.

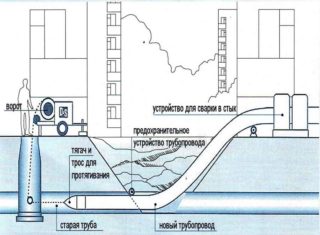

Trenchless option

The cost of this type of installation is higher, but it has certain advantages. There is no need to change the landscape of the site, the time costs will be less.

The trenchless option for laying a water supply system has three varieties:

- Relining. The inner space of the old pipes is filled with new ones made of polyethylene.

- Renovation. It is planned to simultaneously dismantle old communications and replace them with new ones. Performed in cases where the used pipes are of insufficient cross-section.

- Horizontal directional drilling. HDD is carried out with diameters greater than 150 millimeters. The method involves puncturing the soil without damaging the top layer.

The technology of laying a full water supply system from a HDPE pipe by horizontal drilling in the ground requires the use of special equipment - a hydraulic jack. Two pits are dug on both sides of the facility, under which the communication will be carried out. The jack is placed on one side. It drives a pipe horizontally through the soil, onto which a steel tip is put on. After laying, the line is connected to the same systems as in the trench version.

On small sections, for example, under an asphalt road, horizontal drilling is carried out using a special drill with a rod bolted to it. Hammering is carried out with an ordinary sledgehammer.

Cost of work per meter

Prices for laying a water supply system depend on the chosen technology and on the cross-section of the pipe - the larger it is, the more expensive the work will be.

Price per running meter of water pipe laying in the ground:

| Installation type | Approximate cost (in rubles) |

| Relighting | From 1000 |

| Renovation | From 1500 |

| Horizontal directional drilling | From 1500 |

| Trench | From 500 |

The complexity of the site, the urgency of order execution and additional services, for example, insulation, will increase the cost.

Possible errors and difficulties

Experts refer to the main points that can cause problems:

- incorrectly selected pipes;

- lack of sand and gravel cushion under the highway;

- neglect of the assessment of soil composition and temperature features of the climate;

- loose tightening of crimp nuts, fittings.

Do not leave open the ends of the pipes, otherwise debris and sand will get into them.

Even in the southern regions, pipes need to be buried at least one and a half meters and insulating material should be used. Otherwise, even a short-term drop in temperature will lead to their deformation. If frost hits, the water in them will simply freeze.

When bringing the water supply to the house, do not rush to fill up the trench. First, you need to do a test run in order to identify possible problems and eliminate errors in a timely manner. Immediately before backfill, once again thoroughly inspect all connections to ensure that the system is functioning correctly.

Pipe insulation methods

Thermal insulation of water pipes is necessary.This is especially true for the above-ground part of the pipe located outdoors and in unheated rooms.

As a heater, you should choose a non-combustible and moisture-resistant material that will not swell when in contact with condensate. It must be resistant to environmental influences, temperature extremes.

Thermal fiber and basalt wool are used from sheet materials. They retain heat well, but require an external waterproofing layer.

Convenient and inexpensive material - expanded polystyrene. Cases from it are sold in hardware stores. All that is required is to enclose the pipe in a heat-shielding casing and seal it with several layers of adhesive tape. Heat insulators, made especially for pipes, are convenient when working with corners and bends.

Expanded polystyrene is used for both external and internal work, while it is quite durable, which contributes to its reuse if it is necessary to dismantle the system.

If you place the plumbing inside another pipe, an air cushion is formed between their walls, which retains heat. But this is an additional measure, insulation is still required.

To prevent the water from freezing, special electric cables for heating and a warm floor are used as insulation. Thanks to them, the pipes will not freeze even in cold weather. But here you need to take into account the additional costs of electricity.

If you follow all the rules for conducting underground communications, you can independently install a high-quality water supply system that will last more than one year.