Pure water is used not only in everyday life, but also in industrial processes, especially in the food, pharmaceutical, chemical and cosmetic industries. Due to the hardness of the liquid, expensive equipment wears out prematurely, which will stop any industrial facility for a long time. To prevent this from happening, industrial filters are used for high-quality water purification.

Main types, principle of operation and device

In the production process, industrial water is used from wells and surface sources, as well as drinking water from the city water supply.

For initial processing, constructively simple devices are used - filters of coarse mechanical water purification. Their purpose is to "catch" large solid impurities: grains of sand, fragments of silt, rust. Water filtration is carried out through metal meshes with cells of different sizes or by using free-flowing substances: sand, expanded clay crumbs, granular aluminum silicate.

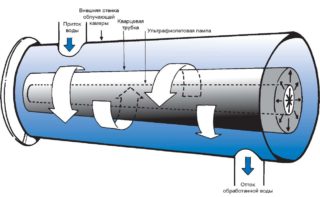

Production devices for fine cleaning are used to trap the smallest particles of organic matter and harmful chemical compounds. Purification in cartridge equipment is carried out using carbon fillers. The action of disinfecting filters is based on the cleansing action of ultraviolet radiation. They are able to process up to 9 cubic meters of water in an hour. The advantage over chlorination is the absence of chemicals added to the water.

Ultraviolet devices kill virtually all bacteria without altering the taste or color of the water.

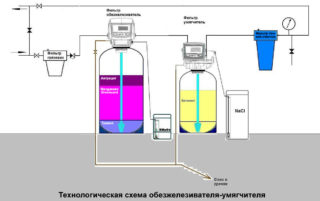

Getting rid of ferrous impurities is possible without the use of reagents. Iron is oxidized by oxygen. It is pumped into the liquid using a powerful compression device. To speed up the process, catalysts are used: materials based on quartz and anthracite.

Membrane devices are suitable for deep water purification. The main element of such filtration equipment, as well as an apparatus that works according to reverse osmosis technology, is a porous membrane made of synthetic materials. It captures particles larger than the pore diameter. Membrane filtering units are needed to obtain ultrapure water for medical and technical purposes, for desalination of seawater, and for purification of sewage effluents.

Application area of industrial filters

In addition to the pharmaceutical, chemical, cosmetic and food industries, enterprises are equipped with purification devices:

- energy and oil refining;

- production of paper and glass;

- agricultural orientation.

The enterprises install equipment for the treatment of incoming water and waste liquid, which is discharged into water bodies.

For each production area, individual water treatment systems are selected:

| Filtration types for complex cleaning | Types of industries | ||||

| Food | Chemical, cosmetic, pharmaceutical | Pulp and paper, glass | Energy | Agricultural | |

| membrane cleansing, electric dialysis, nanofiltration, ozonation, ultraviolet disinfection. | ion exchange, mechanical cleansing, reverse osmosis cleaning, decrease in stiffness. | ion exchange, mechanical cleansing, ozonation. | ion exchange, mechanical cleansing, decrease in stiffness. | mechanical cleansing, aerobic oxidation, decrease in stiffness. | |

Electric dialysis, aerobic oxidation, ozonation, ion exchange and reverse osmosis are used to clean industrial sewage.

Filtration complexes at any enterprise include biological and physicochemical purification of liquids. For this, separate devices are installed. In large industries, equipment is installed that is designed to improve the incoming liquid and purify wastewater. Huge ion exchange and reverse osmosis columns filled with active substances are used as high-performance filter elements.

Industrial wastewater treatment

First of all, coarse mechanical filtration is carried out. In the process of such cleaning, large debris, sand and other solid inclusions are retained.

Small solid impurities, which remain in the form of suspension, are precipitated using coagulation devices.

The most difficult process is the removal of solutes. They are the most dangerous for nature and human health. To get rid of them, chemical reagents are used, but more often bio-purification devices based on activated sludge are chosen. Filtered wastewater is additionally disinfected before discharge.

Criterias of choice

When choosing equipment for water purification, one should be guided by technological maps, standards, technical conditions for certain types of technological process.

Parameters that pay attention to first of all:

- operating mode - uninterrupted or periodic;

- temperature of suspensions and washing liquids;

- device performance and cleaning quality;

- the cost of filter elements and replaceable reagents;

- the presence of additional devices, for example, a manometer for adjusting the outlet pressure of the fluid flow;

- duration of service;

- the possibility of extending the operational life of industrial equipment;

- types of suspended matter to be removed.

Some of the filter elements for removing iron can remove from the water and other compounds that may be needed for production.

The cost of equipment is determined by its type, the type of environment used and productivity. Prices for industrial filters for mechanical water purification start at 10 thousand rubles. The cost of iron removal plants varies in the range of 30–80 thousand rubles. The prices for coal models are approximately identical. You will have to spend a little more on softeners - about 50-100 thousand. Reverse osmosis systems are the most expensive. The most inexpensive reverse osmosis filter of the popular Geyser brand costs 75 thousand rubles.

The use of filtration devices increases the operating life of the equipment, allows you to save the natural environment and get better quality products. Installation requires complex calculations, they must be performed by professionals.