The operating instructions for plumbing fixtures contain data on the parameters of the modes, subject to which the devices will function for a long time. However, pressure surges affect the integrity of thermostats, faucets, boilers and other bathroom and kitchen equipment. The pressure regulator built into the system is able to neutralize a sudden change in water pressure.

Definition and purpose of the water pressure reducer in the water supply system

Water hammers in the backbone network appear when starting incorrectly, causing jumps in the make-up parameters.

Pressure regulators are designed to protect the water supply system from a sharp change in the parameters of the working environment and the damage to equipment caused by them. In other words, the purpose of the water supply reducer is to control and reduce the pressure if the nominal value is reached. For this, a diaphragm or piston is used, with which the water supply is limited.

Gearboxes can have different capacities. The performance of domestic regulators is usually 3 m3 / h, commercial devices have higher technical characteristics - up to 15 m3 / h. More powerful devices are used in production with an indicator of over 15 m3 / hour.

For reliability, device cases are made of the following materials:

- brass;

- stainless steel;

- bronze.

Electroplating can be chrome or nickel. There are reducers for hot water and cold water. One of the types of connection is used when mounting the device: flange or threaded.

Principle of operation

Fluid parameters are optimized using a sensitive diaphragm. At normal values, the spring-loaded diaphragm is at rest. An increase in pressure implies a change in resistance, which causes the sensing device to move back and transmit an impulse to the valve or piston surface.

Water hammer causes a manifold increase in pressure, since water is not compressed. When exposed to the membrane, the piston moves in the closed space of the body, so the device instantly reacts to the slightest changes in parameters and prevents damage from water hammer by limiting the water supply. Thus, the pressure reducer protects the water supply network and the appliances installed in it from rapid changes in the hydraulic regime, which have a detrimental effect on all plumbing devices, causing them to break down.

It is incorrect to install a pressure regulator after the meter, since the measuring device will remain unprotected before changing the hydraulic mode. If you look at the pressure gauges that are installed at the heating point, you can see that the arrows are constantly waving, indicating the dynamics of the parameter.

Types and device

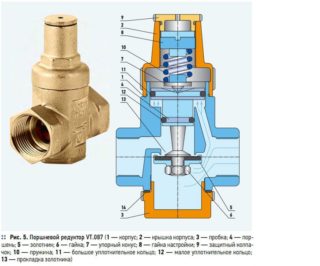

- piston - have the simplest design;

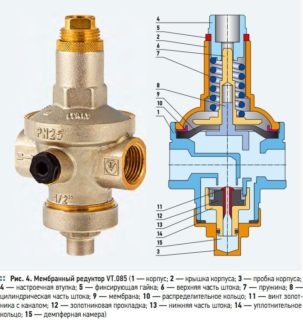

- membrane;

- flowing.

The steel body is equipped with two female threaded ports. Some models are supplied with a pressure gauge tube and an adjustment screw.

The reducer, in which the valve is made in the form of a diaphragm, is a reliable device. It does not require manual configuration. The throughput of the membrane regulator is up to 3 m3 / h. The valve divides the chamber into 2 parts.In the sealed compartment behind it there is a spring, which, having received an impulse from the elastic petal, is compressed, setting in motion a valve that closes the hole. This reduces the flow of water and the pressure in the system decreases.

If the parameter decreases, the spring straightens and the valve opens the passage wider, the water flow increases.

The spring-loaded piston regulates the pressure in the network using a built-in valve, which, when rotated, changes the inlet opening, compressing or releasing the spring. The simplicity of the device and low cost makes it popular with consumers. So that the device does not break down quickly, a water filter must be installed at the inlet, which is sometimes included in the package.

Durable and reliable flow-type pressure regulators. They have no moving parts. The design includes a labyrinth with holes, due to which the flow rate is reduced, as it breaks up into separate jets. Such devices are used at network pressures up to 3 atm.

Main selection criteria

If you choose between piston and diaphragm devices, the former are considered less reliable. This is due to the high sensitivity of the device to water quality: the ingress of sludge particles leads to jamming of the piston valve. Another reason lies in the vulnerability of the elements to corrosion.

Diaphragm regulators are unpretentious and reliable, but their weak point is the integrity of the diaphragm. Pistons are virtually abrasion resistant.

To choose a reducer for a nominal pressure, which is from 4 to 6 atm, you need to be guided by the technical instructions of household plumbing devices. Temperature is another important indicator. If an operating range of up to 40 degrees is specified, the reducer is designed to work in a cold water supply system, for hot water supply this parameter is 130 degrees.

Installation features

The installation of the gearbox can be done independently if the user knows how to experience such work. You will need an adjustable wrench, fum tape or other seal, two ball stop valves and the gearbox itself.

For convenience, a horizontal section is chosen. First, shut off the water supply, then install a valve at the inlet, a filter, a reducer and a ball valve. To prevent leaks, all connections are sealed with tow.

The next step is to adjust the water pressure reducer in the water supply system of the apartment according to the algorithm:

- close the outlet valve;

- open water;

- fix the nominal pressure in the pipeline, usually it is maintained at 3 atm;

- using the key, set the arrow to the indicated value.

Automatic gearboxes do not require manual adjustment.

Operation and maintenance

Housing and communal services install pressure regulators that are designed for high-rise buildings to supply water to the upper floors, therefore, excess pressure on the lower floors is always associated with the risk of fistulas.

Maintenance of the device is reduced to monitoring the pressure in the network. Diaphragm damage due to stem and spring corrosion will prevent the output from being adjusted. Leakage of fluid due to wear of the gaskets also indicates a need for repair. All elements can be easily purchased in the retail network and the gearbox can be repaired.