Drainage pumps in suburban areas perform not the most pleasant operations. With their help, sewage wells, pools, basements are drained, they help septic tanks to discharge purified (clarified) water outside the territory. But, like all equipment of this type, drainage pumping units tend to fail over time. Therefore, the moment comes when the repair of the drainage pumps is required.

How the drain pump works

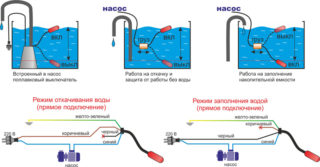

Manufacturers offer float switch drainage pumps. The latter reacts to the level of pumped water. And if it drops to a critical level, the pump immediately turns off. The float acts as a dry run protection.

Breakdown reasons

There are not many reasons for malfunctioning drainage pumps. But identifying one of them is not always easy. In addition, a unit that has been used for many years or a unit that has just been purchased may fail. In the latter case, it may be a factory defect, or mistakes were made during the installation of pumping equipment. For example, the pump was lowered to an insufficient depth, so the suction port was above the surface of the water surface.

Most often, all malfunctions manifest themselves during the operation of the device. It is very important to properly operate it according to the control parameters, which the manufacturer must indicate in the product passport. If the pumping device is used incorrectly, the loads will simply destroy it, disable the working units and parts. These control parameters include the size of the particles located in the pumped water. If they are more than indicated in the passport, this will primarily lead to failure of the impeller or electric motor.

The same can be said if the pump unit is idling. Cooling of the electric motor is carried out by the pumped water. If it does not enter the pump casing, after a few minutes of operation, the motor will overheat and there is a high probability that its windings will burn out.

Lack of prevention can also cause the drain pump to fail. A large number of breakdowns can be prevented if the prerequisites for their occurrence are detected in time.

Types of breakdowns and ways to eliminate them

Breakdowns can be divided into simple and complex. The latter cannot be corrected with your own hands. For example, repair an electric motor. The category of simple faults includes malfunctions that can be eliminated without contacting a service center. Usually this is the replacement of a failed part with a new one or a banal cleaning of the insides of the pumping unit.

A trivial situation - drain pump does not work with float switch - does not turn on if necessary.

The reasons:

- The electrical power cable is out of order.This often happens when it bends, twists, or during transportation one of the terminals of the device has come off. Finding a break is not always possible, so the best solution is to replace it with a new wire. It is important to correctly open the terminal box cover. There is a rubber gasket under it, which creates a sealed abutment to the box. If the cuff breaks, you will need to replace it too. The main task when replacing the supply cable is to accurately connect the cores of the new wire to the terminals. Nothing can be confused.

- One of the reasons concerns the float switch itself. It works on the principle of a lever, which then connects the terminals to each other, which is why power is supplied to the electric motor, then disconnects them. It often happens that the contact planes of the terminals are covered with dirt or rust. They just need to be cleaned by any means, for which you will have to disassemble the drain pump with an external float, clean the terminals and reassemble the device.

- Sometimes a break occurs in the wire that connects the float to the pump. To check if this is really so, you need to install a new wire in parallel and try to turn on the pump. If it works, the problem is in the cable. It also needs to be replaced.

The reasons are really simple. But you don't always have to deal with them yourself. A device in water will create big problems with its opening due to rusted fasteners. Therefore, it is better to take him to a service center.

Second breakdown: the electric motor is humming, but the pump does not pump water... The reasons:

- the supply pipe is clogged;

- big wear of the impeller or complete break of the blades;

- the size of the impurity in the pumped-over water is larger than the passport size;

- the mains voltage dropped.

The first problem is not difficult to solve. It is necessary to lift the pump out of the well, unscrew the supply hose and rinse it with water pressure. The second is solved by more complex manipulations - you will have to replace the impeller with a new one by opening the liquid suction chamber. The voltage drop problem is solved by installing a step-up transformer in the power supply network.

Third nuisance: the pump hums, but does not spin... This is one of the most difficult failures, which is based on bearing seizure. With your own hands, if you are not a pumping equipment repair specialist, you will not be able to eliminate this nuisance. But there is another reason, no less unpleasant. One of the motor windings may burn out. It will have to be changed to a new one or to be repaired in terms of installing new windings (all without exception, even undamaged ones).

When the drain pump is turned on, the machine knocks out... There are two reasons:

- short circuit between the turns of the motor winding;

- short circuit between the cores of the supply cable.

It is impossible to cope with the first reason on your own. The pump will have to be taken to a service center. As practice shows, even in the center, the masters do not take up the rewinding of the engine. Therefore, the best option is to purchase a new pump. The second problem can be solved by yourself. The main thing is to accurately determine that it is the cause of knocking out the machine. To do this, you can use a multimeter by checking the wire for resistance.

To avoid serious damage, it is recommended to periodically inspect the equipment and prevent it.

Prevention and maintenance of the drain pump

In order for the pumping unit to serve for a long time and to create no big problems, it is necessary to follow the manufacturer's recommendations. This applies to the rules of installation and operation.

Once a year, the drainage pumps must be opened and cleaned of stuck dirt and debris inside the compartments of the device. At the same time, parts are checked for wear. This primarily concerns the protective mesh located inside the suction pipe and the impeller. There are special requirements for the latter: it should not be smaller in size. This affects the performance of the unit. If the parameters of the impeller become less, it must be replaced.

It is imperative that during the maintenance process the float is checked, the terminal box is opened, in which the contacts are cleaned. The supply wire is checked for kinks and wire breakages. Please note that even a simple cleaning of the internal cavities of the drainage pump will increase its service life several times.