The task of the caisson is to protect the inner space of a well or reservoir from aggressive external environmental influences. However, over time, even the most resistant material wears out. Repair of the caisson is required for any leakage that could cause a leak.

The main reasons for repairing a caisson

In garages, this equipment is used as basements or observation pits. They are sealed and can be installed in the ground with any level of moisture saturation.

The caisson can be plastic, reinforced concrete or metal. The first type of structures is not susceptible to corrosion, but it is easily deformed due to the displacement of soil layers and under strong liquid pressure, therefore, their restoration is not cost-effective.

Reinforced concrete products are durable, but they consist of several volumetric parts. As a result, even a small pressure leak in the caisson is difficult to eliminate. Leakage can lead to damage to the property inside, and replacement is associated with a lot of difficulties due to the large mass. Therefore, the best solution when repairs are needed are restoration work that excludes drastic measures.

Most often, they perform the installation of iron models. Tanks made of metal are easy to install, but wear out quickly at the welded joints. As a result of the development of the corrosive process, the tightness of the seams is broken, and then the entire product. Timely elimination of the centers of damage prolongs the operational period of the frame.

Repair methods

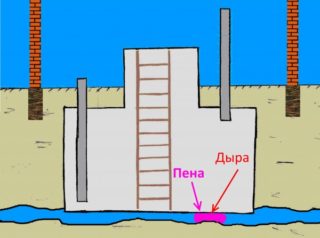

An iron caisson is a round or square steel box with walls more than 4 mm thick and with ventilation ducts for condensate drainage. An asphalt or bitumen-gasoline solution, as well as bitumen mastic, is used as a waterproofing layer. If the protection is performed poorly, over time, holes appear through which liquid begins to seep.

It is possible to decide which method is best to use to eliminate damage only after studying the cause of its occurrence, as well as analyzing the conditions of the general condition of the equipment. It should be borne in mind that the tank, inside which it is planned to carry out repair work, has a limited size.

- To close the hole formed in the caisson, you can apply a patch of roofing material or cold welding. To do this, a wooden cork is inserted into the hole, which swells and tightly isolates the damaged site. After that, the surface is dried, and roofing sheets are laid on it, fastened with bituminous mastic. The structure is reinforced with a mesh and filled with a mixture of liquid glass and cement with a mortar with a thickness of at least 150 mm.

- If several leaks are found in the tank, this indicates the need for overhaul. The process is carried out in several stages: the top is cut off, a cement screed is laid on the floor, then an insert with parameters 5-7 cm less than the size of the bottom, everything is fixed with stops and again poured with concrete from above. After the screed hardens, the upper part is welded into place.

In order not to carry out time-consuming recovery operations, it is necessary to carry out a regular revision of the device.

Preventive measures

Timely detection of defects allows you to eliminate malfunctions with minimal repair costs.

- Installation of structures is carried out on a sand and gravel cushion with a thickness of more than 20 cm. Sand is poured between the walls of the well or pit and the tank. Breakdowns are most often the result of ignoring SNiP during installation, as well as standards regulated by GOST and TU at the production stage.

- It is necessary to take care of the waterproofing of the installed container at the installation stage. The walls of the chambers must have sufficient strength characteristics to withstand the loads created by the movement and expansion of the soil layers.

- To avoid corrosive processes, it is required to exclude increased moisture formation. For this, the cold bridges in the heat-insulating coating are removed, and an exhaust system is installed.

- Metal containers should have good roofing felt or asphalt waterproofing and anti-corrosion treatment.

- Plastic tanks should be installed in well-drained sandy soils or special soil preparation should be carried out.

It is better to do a preventive examination of the connecting seams for cracks, holes and other defects in the spring. At this time, it is clearly visible whether the repair of the caisson in the garage is necessary: the leak on the floor will be noticeable to the naked eye. Work is mainly carried out when the groundwater level is at its lowest, in late summer or early autumn.