Hydraulic structures sooner or later fall into disrepair. This happens for several reasons - a break in the pump or jamming it in the casing, skewing of the vertical line due to installation problems, silting of the bottom. If the water began to flow intermittently or disappeared altogether, it becomes necessary to inspect and repair the well. Depending on the cause of the breakdown and the type of source, the price is formed for current and major well repairs.

How to determine the cause of a breakdown

If the safety rope is incorrectly selected to hold the pump at a certain depth, the unit may break off and fall to the bottom. The last thing that the owners of the well will notice is the flow of dirty water from the tap. The equipment will still work for several minutes, sucking in mud from the bottom of the well. Then the casing will be clogged with silt and the pump will shut off. At the same time, it will be difficult to get it, because due to vibrations, it will bury itself in the sand. In this case, you will have to call professionals with special devices such as a spider milling cutter.

The most harmless reason is incorrect operation of the pump due to power surges. To make sure that there are no breakages in the well, you need to turn off the equipment, remove it, clean it and install the stabilizer. Sometimes a poor water supply is associated with a change in flow rate.

Dirt in the water is an indication of wear or cracks in the casing. Metal rusts over time, and plastic can burst due to low temperatures. Sand or clay gets into the water through the crack.

By the time between turning on and off the pump, you can determine that the well is silted up. It takes longer to fill after pumping out, the equipment does not work at full capacity, so it takes more time.

You can try to repair the water well with your own hands. This is possible if the volume of work is small, for example, you just need to flush the source. In this case, it is necessary to take into account where it is located - is it possible to direct water into the garden or it will pour out into the equipped area.

The main types of malfunctions and the corresponding repair

With some serious breakdowns, it is necessary to repair the old well or drill a new one. Even if the prices do not differ significantly, the owners prefer repairs, since the documentation for the construction of a new water source must be reissued. The same happens if the water goes deeper - you need to deepen the old source or equip a new one. Many people decide to drill a needle-hole - it is much cheaper, and in case of a breakdown, another one can be made.

It can be difficult or impossible to restore the source's working capacity after unprofessional intervention, so you need to assess your capabilities and skills well before starting to diagnose a breakdown.

The procedure is almost always the same:

- Determine the quality of the pumping equipment and water distribution installations.If, when the device is connected to a regular hose, the pressure remains good, then it is not in the well and not in the pump. If the pressure is weak, you need to inspect the source.

- Try to install another pump. If the water supply has improved, you need to repair or change your unit.

- If replacing the pump did not help, then the problem is in the well - it is repaired, the casing is changed, or washed.

It is necessary to check everything in order, not excluding any node. To inspect the integrity of a pipe, for example, special tools are needed - a camera with which the walls are inspected. In such cases, it is better to call a team of workers who regularly repair wells.

One has to be careful about the quality of the water. A putrid odor usually indicates bacterial contamination. Wastewater from a septic tank may have entered the source. For this, an analysis is made in the laboratory. The chemical smell or taste of the liquid indicates the ingress of harmful substances through the head or groundwater. You cannot use such water until the sanitary station issues a conclusion.

Repair in case of wire breakage

The use of low-quality materials leads to the fact that metal products rust under the influence of moisture. If the cable breaks and the pump falls into the well, the first thing to do is to get it. If it is possible to hook the device with a hook, then later it is cleaned and reinstalled in the well.

A problem can arise if the casing is very narrow and the electrical cable is trapped between the tool body and the wall. In this case, use a heavy object tied to a rope to push the pump down and pull the cable. Usually they try to fasten all the cables with clamps at the installation stage so that none of them sag.

During installation or repair, a tool may fall into the source. If it's made of metal, a magnet on the rope will help. In other cases, a milling cutter is used, but the tool or pump housing will inevitably be damaged, after which you will have to buy a new pump.

Washing when silting up

Silting occurs if the well is operated irregularly. Summer cottages, which are used only in summer, are subject to this problem.

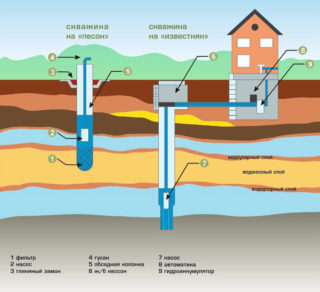

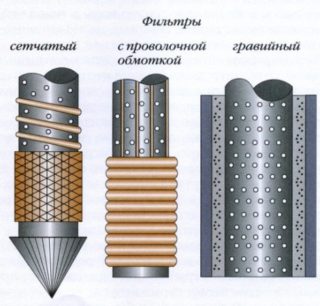

The filter is at the very bottom, but it is not able to catch small particles of dirt or sand. Sooner or later, the aquifer is completely filled and the productivity of the well decreases.

The following cleaning methods are used:

- pumping;

- purge;

- flushing.

The well is pumped with a special pump that can remove even small stones. Water is poured into a vegetable garden or into a sewer truck, if it is not desirable to fill the territory.

For blowing down, pipes are lowered through which air is supplied. It lifts all the dirt from the bottom, and the pump pumps it out.

The source is washed with the help of a strong pressure of water supplied from the outside to the inside. In this case, the sludge layer is washed away from its place and pumped out. For these purposes, it is better to use more powerful pumping units that are capable of sucking in dirt and large particles of debris.

Sometimes they use a bailer - a pipe with which you can scoop out the sand at the bottom and raise it to the surface. When sand gets into the pipe while lowering it down, a valve is triggered to prevent soil from spilling back into the well. With the help of a bailer, you can also deepen the source.

Replacing Filters

After installing a new filter, the pipe is lowered back. Sometimes there are situations with damage to the walls of the pipe, if it is made of plastic.Any careless action may lead to the need to replace the casing.

Casing repair or replacement

If there is a crack inside or a curvature of the shaft occurs, the old pipe must be removed using one of the methods used by professional workers:

- Stretch extraction. With the help of special mechanisms, the end of the pipe is gripped and removed. If a tension arises that exceeds the plasticity limit of the material, it bursts and then you need to grab the remaining part below.

- Tension of the pipeline body. A mechanism is lowered down, which clings to the lower edge. Reinstallation of the extracted pipe is not possible.

- Rocking. Before this, the soil around the pipe is moistened, and the vibration pump is lowered down so that it works for a while, acting on the walls, so that the soil falls behind and loosened up. Further, the pipe is easily pulled out by the tension method. Reusability is sometimes possible.

- Unscrewing. Drilling equipment will be required, which is fixed inside the well, then several clockwise turns are made, and the pipe is retrieved.

Repair and isolation works in wells are carried out only at oil and gas production enterprises. In drinking water sources, such types of work are not used due to the complexity and high cost of repair equipment.

When to contact professionals

Especially difficult cases require professional help - replacement of casing and filter. In any of these situations, it is necessary to dismantle the well pipe. The events require the involvement of heavy construction equipment. At the same time, the prices for underground well workover are not comparable to the quality of work done by specialists.

Performing such actions on your own may entail major repairs or the need to drill a new well. Therefore, it is better to entrust everything from start to finish to a professional team that provides a guarantee.

The cost is formed on the basis of several parameters - the depth of the source, the cause of the breakdown, the need to use special machines. The possible expense of funds for new materials is taken into account if they are damaged during the repair. Drilling a new well from scratch, in addition, takes time, because you have to obtain a permit for construction work.