In small suburban areas, you can rarely find a centralized water supply system. People mainly use the water obtained from the ground. The mining method may differ. Deep wells are dug out over large areas, reaching the limestone rocks. Small areas are equipped with a shallow bailer. Pumping equipment is needed to bring water to the surface. If it is not possible to purchase an electric unit, you can make a hand pump for water from a well with your own hands.

Why do you need a hand pump

In the 21st century, even the most remote villages and summer cottages have been electrified. There is no need to pump water using physical strength as before. Electric pumps with a throughput of more than 100 liters per minute are installed.

The pump for manual transfer of water acts as an auxiliary mechanism. However, in some situations, this may be the only way to obtain drinking water.

- If an electrically operated device becomes unusable, it will take time to repair. During this time, a hand pump will come in handy.

- In summer cottage villages, there is a practice of regularly rolling power outages in order to save money. Having the ability to extract water manually, the owners of the site cease to depend on public utilities. Even with a constant, uninterrupted supply of electricity, you need to have a backup.

- Most of the country houses are sold with adjacent territories that are not yet suitable for normal life. Until the owner supplies the electric pump, you can manually extract water from the well.

Thus, the construction of a pump for manual water intake is a necessary measure.

Varieties of the device

Well pumps can have a different principle of the internal structure, differ in the type of injection mechanism. There are 4 types:

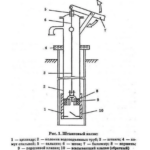

- Piston pump. There is a piston check valve inside. The principle of operation is based on lowering the pressure by rarefying the air in the inner space. Under the action of pressure, the water rises up and is pulled out.

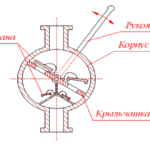

- Wing-type. It is based on the use of centrifugal force, which makes the water rise up the pipe. This is possible thanks to the impeller installed inside. The impeller is set in a circular motion by turning the knob on the outside of the pump.

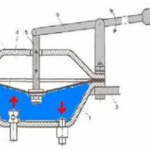

- Membrane. The device is similar to the first option. The difference is that instead of a piston, there is an elastic diaphragm in the inner chamber. When the volume of the chamber changes under the action of a mechanical drive, a low pressure is created, forcing the liquid to come out to the surface.

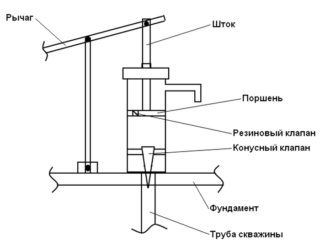

- A sucker rod pump is a type of piston pump. The mechanism inside the chamber does not move with full amplitude, but only partially. Water enters it in small portions over several movements. As soon as the entire volume is filled, it begins to pour out through the hole located on top. To prevent water from flowing out of the pump chamber during movement opposite to the retractor, a rubber check valve is installed in it.

The most versatile is the piston pump. It serves on average longer than others and requires less repair due to its simplicity of design.

Advantages and disadvantages

The benefits of using homemade hand pumps for water include:

- Low cost compared to other wellbore fluid delivery methods.

- Complete autonomy from any power source. No need for electricity and diesel engine.

- The hand pump does not have any special conditions at the installation site, and there are also no operational requirements.

- The simple collapsible design contains primitive parts and assemblies that can be bought in any market for little money in the event of a breakdown.

- The cost of installing a hand pump will be minimal, there is no need to involve workers and technicians.

- The design is so simple that every owner can assemble and install the pump in a garage, which will save money on buying a ready-made unit.

The disadvantages of a homemade hand pump for wells are much less. The throughput of the mechanism is low in comparison with electrical analogs, since it is limited by the physical capabilities of a person. For filling containers with a volume of 200 - 300 liters, the manual drive is ineffective, since it takes too much time. Water cannot be produced without direct human participation, unlike automatic systems.

Criterias of choice

When choosing a hand pump for a well, you need to take into account the depth of the tank. When buying, look in the technical specifications, from what maximum depth it is capable of pumping water. The throughput of handheld devices is low, but also different. Depends on how much water the inner chamber takes in one piston movement.

Units with a high capacity, as a rule, require pumping the handle with great effort, because the weight of the piston is proportional to its size. Therefore, retirees and people with disabilities should choose a small design.

The device must be fixed to the well hermetically, without cracks and gaps. Select it according to the pipe diameter. The most common diameter is 125 mm.

Do not forget about the material from which the pipes are made. A hand pump for a well made of plastic pipes is preferable as polypropylene is lighter and less prone to wear over time.

Take care of the comfort while pitching. The handle should be comfortable and not pinch your palms.

Well installation

The pumping efficiency and service life depend on the correct installation of the pump. There are some rules to follow.

First of all, you need to find out if you need an additional filter between the pipes. Some pumps are not designed to pump raw water. Make sure all parts are in place, valves are working properly, and there is no excessive friction between moving parts.

You need to put the pump on the well and look at the quality of the connection. If everything is in order, you can start connecting. Common bolts and nuts are used. Slide the device onto the pipe so that the bolt hole rim on the well aligns with the pump holes. Insert the bolts and tighten with the nuts as tight as possible.

Even if there are no gaps between the devices, it is recommended to make an additional seal. For this, tow or electrical tape is suitable. Under the influence of temperature and weather conditions, pipes can slightly deform with the formation of leaks. For maximum results, the perimeter joint can be coated on top with a liquid sealant.