A well is an expensive construction, especially if it is supplied from artesian waters. In this case, you will have to spend money not only on the construction of a hydraulic structure, but also on obtaining a license. The best option would be to agree on the creation of a common source of autonomous water supply for two houses.

Advantages and disadvantages of the method

The plus of such a water supply scheme is obvious - it will be cheaper to create a well and register it. Maintenance costs will also be lower. But there are also significant disadvantages:

- possible conflicts between neighbors over territory or electricity;

- problems with the sale of a site by one of the participants in the scheme;

- errors in the calculation of the flow rate, leading to a shortage of water for all consumers.

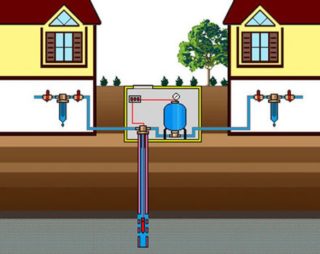

A well for two houses is more difficult to build, since it must be equipped with a caisson, which is necessary to dilute the water supply. There may also be a problem with the installation of water meters that are required for licensing. After all, there should be two or more, depending on the number of well owners.

Connection diagrams

There are three main ways to connect water supply from a common well to two sections:

- with one pump and one accumulator;

- with one pump and two hydraulic accumulators;

- with two different pressure devices.

The first method is suitable if the neighboring buildings are located close to each other, the maximum distance is 100 m. The connection of the system elements goes in the following sequence: pressure equipment - non-return valve - pressure switch and automation unit - hydraulic tank. Next, a tee is mounted on the pipe that comes out of the accumulator and wiring is performed. The drive itself is installed in a caisson in such a situation.

The second option is used if the buildings of the owners of the well are located far from each other. The connection diagram is as follows:

- Mount the tee on the discharge pipe.

- Highways are bred from it to each house.

- Storage tanks are installed on water pipelines.

A similar option is used if the water consumption in the well is large. It is very difficult to find a giant hydraulic tank and install it in a caisson. It is wise to use two small containers. The pressure switch and the automation unit are installed before wiring.

Individual hydraulic accumulators with the installation of a pressure switch in front of each will be required even when the well will supply more than three houses. In the caisson, in this case, only piping to the buildings is performed.

At high flow rates, it is especially important to calculate the flow rate of the source so that its rapid emptying does not occur. If the water level drops, there is a risk of the pump running dry. Prolonged operation, if dry-running protection is not installed, will result in equipment failure.

The well flow rate must exceed the total average water consumption of users. The flow rate of sandy water intakes does not exceed 1.5 cubic meters per hour on average. Such a well can provide a maximum of two houses. For three or more buildings, an artesian well will be required. Its cost is higher than the sand one and it can turn out so that it is almost not economically profitable even in comparison with drilling three wells into the sand. But such a device is much more durable, and the water from it is cleaner.

The connection diagram of one common well for two houses with two pressure devices allows solving the problem of productivity and power in the redistribution of water resources. The choice of a model of pressure equipment depends on the conditions in which it is planned to be used. Each combination of pressure equipment has its own characteristics.

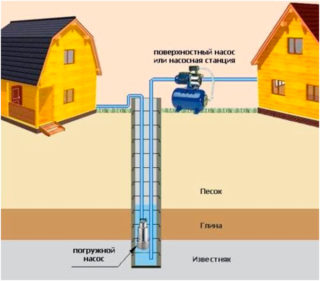

Two submersible pumps

If the water surface is located at a considerable depth and the section of the casing is sufficient, two submersible pumps can be installed in the well. The main difficulty of such a scheme is that each device must be freely suspended, and at the same time they must not touch the walls of the shaft.

Unlike vibration equipment, which can damage even a steel pipe, the ratio of centrifugal pumps to the structure is more gentle. But even from them there is a slight vibration. To avoid damage, it is best to have a gap between the equipment and the wall.

There are two ways to equip a well with such pumps. The first is by means of a conductor on which both units are suspended. To hold the suspension, a common cable with a large margin of safety is used. The water supply pipe of the lower pump bends around the upper one by means of fittings.

The second method assumes that the upper apparatus is suspended in the shaft, and a platform is arranged for the pump from below, which is held by two cables. The water supply pipe is assembled in the same way as in the first version.

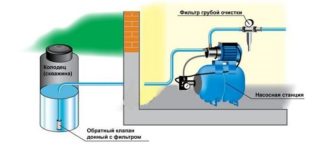

Two surface pumps

Pressure installations located on the surface are not so critical to the section of the pipe, since only hoses are placed in the shaft. Both pumps work independently of each other. Sometimes it is not even necessary to connect each unit to a hydraulic accumulator. When using one device only for watering the site, the outlet hose from it can be passed directly.

But such installations have a drawback - their efficiency is possible only with a well depth of up to 8 meters, which sets a rather rigid framework for their use.

The scheme with the use of two independent water supply pipes is used for borehole shafts of standard size. In Abyssinian wells with a 25-50 mm “needle” section, there is enough space for only one hose, so a tee is mounted at the entry into the well, and each device is connected using a non-return valve. The disadvantage of this scheme is the impossibility of simultaneous operation of two stations.

Submersible and surface pumps

Combined connection is used when none of the devices individually is able to maintain the required water supply parameters. To create the required pressure in the system, two pressure devices must be connected in series to one well. Submersible equipment supplies liquid to the pumping station, and this, in turn, provides sufficient head in the water supply system.

Since both devices in such a scheme complement each other, their work must be coordinated:

- make sure that both pumps have the same performance;

- synchronize the start of the devices by connecting them in parallel to the pressure switch;

- use dry run monitoring for each unit or provide general protection.

Surface and submersible pumps may not be complementary. If technical characteristics permit, they can be operated autonomously to organize water supply for individual farms.

In order not to bother with two pumping units, inventing special fasteners and installation methods for them, it is easier to buy a powerful pump for two sites, and equip each house with an individual hydraulic accumulator.The setting of the automatic start-up and shutdown of pressure equipment can be done so that the unit can be started from any area.