Drilling water wells with your own hands allows you to save on renting a drilling rig and wages for workers. Most often, people prefer to make a well, since it takes up less space in size, and less soil will have to be removed from the site after the completion of construction work. There are several types of wells and methods with which you can independently get to the aquifer.

Well types

On the site, you can equip several types of sources that differ in design. In this case, it is necessary to clarify at what depth the water is in order to choose the optimal place. Usually, when preparing documents, the owners are advised one or another location. In especially difficult cases, you have to spend a lot of money to get to the water, for example, if the house is located on a hill, the depth of the well automatically increases by a distance equal to its height.

Types of sources that you can do yourself:

- Abyssinian well - the simplest design;

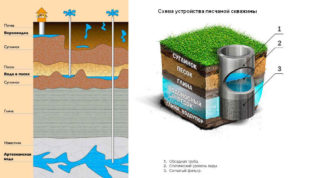

- borehole for sand - depth up to 12 meters;

- artesian - a well on limestone.

The advantages of arranging an Abyssinian well:

- speed - it takes several hours to install and then you can use the source;

- there is no need to buy expensive materials and rent drilling equipment;

- long service life of 10 - 15 years, if you properly equip the underground water intake part.

Basically, the needle is used on sandy loam. If the soil consists of a large amount of clay, it will be difficult to break through it, and the filter will quickly silt up, and the well will stop producing water.

If the distance to the water surface is over 8 meters, it is necessary to additionally equip the caisson for the pumping station several meters below ground level, which will entail additional costs of time and money. The problem is that the station cannot lift liquid from a great depth, and the submersible pump does not fit into a very narrow hole in the casing. Before proceeding with the arrangement, you need to find out the depth of the aquifer and determine the type of soil.

Well on the sand

Sand holes can be drilled to a depth of 35 meters, but they have many disadvantages:

- insufficient natural filtration of water, since sand does not remove dissolved substances and waste water residues, as well as pesticides and other types of agricultural chemicals;

- the well can operate for no longer than 20 years, then the siltation process takes place and a major overhaul with flushing is required;

- sand clogs the filter, which can be cleaned by removing the complete casing;

- the need for regular cleaning of the pump, since its filter element is also clogged with small solid particles.

Nevertheless, most of the existing wells are sandy, since they are much cheaper than artesian ones.

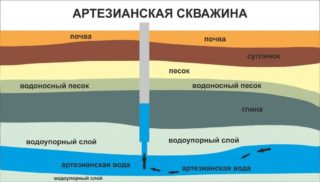

Artesian well

The advantage of an artesian well:

- there are no seasonal fluctuations in the water level, which has a positive effect on the operation of pumping equipment;

- the liquid is cleaner - it can be used raw without boiling;

- dissolved minerals have a positive effect on health;

- no repairs and maintenance are required, subject to quality installation;

- long service life - more than 50 years.

The deepest artesian well drilled by man reaches a depth of over 12 km. It is located on the Kola Peninsula and is listed in the Guinness Book of Records. Back in the 13th century, the Chinese manually drilled very deep wells - up to 1.5 km.

There are practically no drawbacks to artesian wells. The only thing is the presence of a large number of iron ions, but this depends on the composition of the rock in a given region. After pumping for 2 to 3 weeks, the liquid is sent for analysis in order to install the correct filter and use the source.

Selection criteria for your site

First of all, those wishing to drill a well are interested in the price of work and materials. In some cases, residents do this manually to minimize the cost of arranging the source. For example, it will not be possible to equip an artesian well cheaply, so drilling companies offer economical options, but this affects the quality of the water and the service life.

The best option is a shallow sand well, if the geological location of the site allows and the aquifer is located close to the earth's surface. This is not always the case, so you have to spend money on deep drilling.

If there is already a source on the site that provides the house with water, and a well is needed to water the garden, it is enough to make an Abyssinian well with manual pumping of liquid. It is possible to make a water well manually without equipment in one day, using the materials at hand.

Diy drilling methods

- auger drill - as it deepens into the thickness of the earth, it is built up with new sections of a metal pipe;

- bailer - a device with sharp teeth at the end and a valve that prevents the earth from spilling out back into the mine;

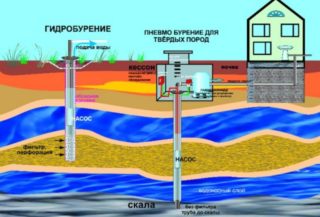

- using soil erosion - hydraulic method;

- "needle";

- shock-rope method.

Using technology auger drilling, you can dig a well up to 100 meters deep. It is difficult to do this manually, therefore, stationary electrical installations are used, and the drill is built up with new sections as it deepens. Periodically, it is raised to pour out the soil. So that the walls do not crumble, a casing is laid after the drill.

If the drill cannot be built up, a sharp-edged bailer is attached to its base and the drill screws it in a few more meters deeper. Next, the pipe is lifted and the accumulated soil is poured out.

Work with the auger can be carried out on soft soil. Rocky terrain, clay deposits and muds are not suitable for this method.

Bailer Is a metal pipe with solid steel teeth soldered at the end. Slightly higher in the pipe there is a valve that blocks the exit to the ground when the device is lifted from a depth. The principle of operation is simple - the bailer is installed in the right place and manually turned, gradually deepening into the soil. The method takes longer than using electrical equipment, but it is economical.

The device is required to periodically lift and empty the earth from the pipe. The deeper the pipe goes, the harder it is to lift it. In addition, scrolling requires brute force. More often than not, several people work. To make the soil easier to drill, it is washed out with water, pouring it into the pipe from above using a hose and a pump.

Hydrodrilling also uses a bailer to soften soil layers that the liquid cannot cope with even under pressure.

Rope percussion drilling Is the oldest method still in use today. The principle is to lower the metal sleeve into the casing and gradually deepen the well. For drilling, you need a stand with a fixed cable. The method requires time and frequent lifts of the working pipe in order to empty the soil. To facilitate the work, use a hose with water to wash out the soil.

The "needle" method for the Abyssinian well: when the pipe is lowered, the soil is compacted, so it is not thrown out to the surface. A sharp ferroalloy tip is needed to penetrate the soil. You can make such a device at home if the aquifer is shallow.

The method is cheap and time-consuming. The disadvantage is that such a well will not be enough to provide a private house with water.

Tools and materials

The drill stand can be welded using a conventional machine. The auger hand auger is bought in the store. It may require additional threaded sections. Their number depends on the estimated depth of the source.

Plastic pipes are often used for casing, although they are not strong enough to withstand ground movements. Concrete casing or metal pipe lasts longer, but metal is prone to corrosion. The optimal material is thick-walled plastic that is resistant to low temperatures. When connecting parts, you will need to pay attention to the quality of the soldering - some types of plastic require special devices.

For independent drilling of wells, you can use the devices that companies lease. This will allow you to get the job done faster without having to buy tools.

Preparatory activities

The most important step is determining the depth of the aquifer. It can be determined by plants - birch, black poplar, alder grow near water sources. The wood of these species used to be used to make frames. If the wire in the tree begins to rotate in the hands, then there is an underground source nearby.

If the aquifer is shallow, midges and mosquitoes will circle over this place in the evening. The presence of liquid is indicated by fog or excess dew in the morning. If there is a pond or lake nearby, it always means that the water is shallow.

If none of the above signs indicate the proximity of an aquifer, you should contact a specialist geologist. In addition, a technical passport must be made for all hydraulic structures.

Make trial drilling more profitable. You can bump into stones or a clay layer, so you need to look for a place in the sand so that the water is cleaner. After the sample, the fluid must be taken for analysis and only after that the stationary well must be drilled.

How to avoid mistakes

You cannot dig the source in autumn or spring, as at this time of the year the groundwater rises higher. The depth is determined in summer, especially if it is planned to arrange a well on the sand.In a drought, the liquid can go deeper and it will be necessary to dig a ready-made well.

It is impossible to equip the source of drinking water near septic tanks, garbage dumps or swamps. Fluid in such places will need additional filtration.

Sometimes, while drilling, you can get to the top water - surface sources. They are usually shallow, the flow rate of such a well will not be enough to meet the needs of a private house.

Great way. Thanks for posting. Best regards, Anatoly.

There is a drilling rig on sale with a gasoline two-stroke engine worth 10,000 rubles - a very good solution, but everything else is better to do yourself, since the auger and nozzles are very expensive. A drum winch is also needed, since it is unrealistic to pull out the auger wrapped in clay by hand. And, of course, it is necessary to connect the auger to the motor with a good strong cable, so that in the event of an accident with the attachments, you can get the auger. Good luck with your work and we will be with water!