Often inexperienced craftsmen decide to make a well in the well, believing that in this way they can save on the meters already available in depth. But such views are fundamentally wrong. In addition, not all specialists are ready to take on this type of work.

Is it possible to make a well in a well

In theory, no government documents, including SNiP, prohibit drilling inside an existing mine. Moreover, if it has completely exhausted its debit. But experienced craftsmen are often guided by common sense before starting or abandoning work. Weigh the situation from different sides:

- Assess the safety of the well itself. The probability that during drilling its walls will collapse or not.

- The probability of the negative impact of the drilling rig on the already selected soil is calculated. In 85% of cases, heavy equipment simply goes down under its own weight when the auger is introduced into the depths.

- The complexity of bringing the casing upward (of the section that will be located in the empty space of the mine).

- The risk of stumbling upon quicksand when carrying out work in this particular area.

- There is a high probability of the tool falling into the finished well shaft. This will entail additional labor costs for its extraction, as well as loss of time.

- If the concrete rings are shifted about their axis, this indicates that the sandy horizon is curved beneath them. That is, the specialists will have to work hard so that the mine does not collapse completely.

When drilling a well in a well, a master who wants to save money, on the contrary, bears additional costs. The price per meter of work performed always includes the stages of installing the casing, the type of material used for the string (metal, polymer), as well as its diameter. The pipe will still need to be additionally strengthened, since the column cannot simply stand in the air without supports for 10-18 meters (the average depth of drinking wells).

Features of the arrangement

If, nevertheless, a decision is made to drill in the well shaft, it is necessary to take into account the following features of the work and arrangement of the source:

- It is better to form a well in late summer or early autumn, when the GWL is as low as possible.

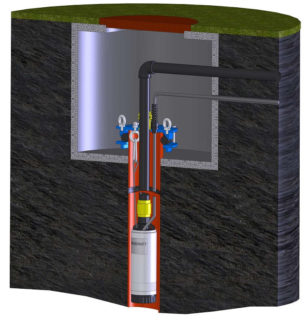

- So that the water from the well shaft does not interfere with drilling, you need to install a special pipe to the entire depth of the source (the so-called conductor). Thus, the channel of the future well is well protected from moving ground masses and waters. If necessary, the jig is gradually lengthened using stackable couplings.

- It is important to protect the new aquifer from the ingress of the environment from the existing source. More often, open wells contain organic matter: fallen bodies of birds, bats, etc. Once in a new layer, they pollute it. But neighboring wells can also be fed from one horizon.

- After the completion of drilling and installation of the casing, it is advisable to fill up the shaft of the old source and compact it well. But so that the column is not led.

- When working on level ground, the flushing fluid is discharged into a sump (a special depression next to the drilling zone). In the case of work in a well, there is no such reservoir. Therefore, specialists have to show additional ingenuity, to complicate the usual design while drilling.

The most optimal option for forming a source in an already finished old well is an Abyssinian well by hand. Provided that the depth of the mine does not exceed 8-10 m. Here it remains to drive in a pipe-needle and bring it to the surface.Deeper work will be technically difficult for drillers.

Stages of installation of a well in a well

There are two ways to drill in an existing source mine:

- Installing a conductor of sufficient diameter. It will really help, even if there is still water in the well. From the conductor, a branch is made into the sump and drilling is performed.

- Fill the well shaft to the brim with flushing liquid and deepen gradually. But this method is very risky. First, it is difficult to maintain the viscosity of the drilling fluid under these conditions. Secondly, if it hits the limestone and breaks it open, the entire mass can roll over the tool.

The second drilling option is less realistic and is rarely used. To make a well in a well, the master will have to look carefully for professionals who are ready to take on this. It is worth being prepared for a possible distortion of the foundation of the house under the weight of technology. Perhaps it is better not to risk it and just drill a separate well at the site, and just fill up the well shaft.

When forming a new source in the well, it is advisable to put a plastic casing pipe. It is lighter and does not corrode.