When arranging an autonomous water supply system using a well, a good submersible pump is needed. With its help, it is possible to supply liquid to the line and maintain a constant pressure in the pipeline. Among the popular devices well-proven submersible pumps Belamos.

Scope of the submersible pump

The device is widely used to organize such systems in a suburban area:

- water intake of clean drinking water;

- its transportation to the highway;

- watering and irrigation of the site;

- filling storage tanks;

- small household options (car wash, etc.).

Belamos pumps are in demand among masters for unpretentious installation, high performance.

Device and principle of operation

All Belamos pumps are structurally divided into the following types:

- Centrifugal. They are considered the most powerful. They have an impeller with blades. They work on the principle of centrifugal force. When turned on, the shaft starts to rotate. Due to this, the pressure in the chamber drops and water flows inside through the inlet pipe. The blades strongly press the liquid against the walls of the chamber, thereby pushing it up to the outlet. The work cycles are continuous. The maximum lifting height for the Belamos centrifugal unit is 120 meters.

- Screw (they are also screw). The most simple and low-performance modifications of Belamos devices. They work from a worm rotor (analogue of the Archimedes screw) located inside the flask. The shaft is made of durable polypropylene. The motor for such devices is single-phase. The starting winding is powered through a capacitor. For shallow wells in sand, these models are most suitable. These types of Belamos pumps can be installed in wells with a cross section of 80-140 mm. Using a screw pump, it is permissible to pump water with impurities in the amount of 300 g / m3.

- Vortex pumps Belamos. They work by creating a water vortex in the working chamber. They are considered the most optimal in terms of maintaining a stable pressure in the system. The impeller of the vortex devices is brass. The motor is single-phase. The pumps are intended only for clean water and wells with a diameter of 110 mm and more.

All Belamos devices are equipped with a ceramic-graphite mechanical seal, a check valve and a stainless steel body. The engine is cooled with environmentally friendly petroleum jelly filled in.

Advantages and disadvantages

Among the main positive aspects of Belamos pumps, users highlight:

- acceptable cost of devices;

- long service life;

- optimal performance;

- availability of a factory warranty for all models;

- the ability to equip the pump with automatic equipment, which is always available;

- reasonable power consumption.

Of the minuses, the following are noted:

- lack of smooth start;

- the presence of only one protection - against overheating;

- inaccessibility of the option of adjusting the frequency of rotation.

It is important to remember that even the most expensive pump can fail without proper maintenance and proper operation.

Review of Belamos models

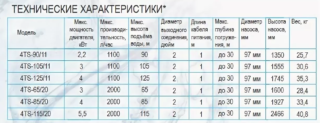

- TF series. The units are equipped with a floating polymer impeller.The head of these devices varies in the range of 42-195 m. Productivity - 2.7-5 m3 / hour. The diameter of the device flask is 3 and 4 inches (96-110 mm). The temperature of the pumped-over water is 0- + 40 degrees. For pumps of the TF series, the content of sand impurities in the water is not more than 150 g / m3. The most popular models in the series are TF-60, TF-80, TF-150. The narrowest of the presented modifications is the TF3 pump. Its case has a diameter of only 75 mm. At the same time, it is capable of pumping water with a small amount of impurities - 180 g / m3. From the model range, the devices TF 3 40, TF 3 60, TF 3 110 are especially distinguished.

- SP series. These submersible units have an Archimedes screw as an impeller. The productivity of the plants is 1.7-2.5 m3 / hour. Case diameter - 3 and 4 inches.

- TM series. Flask diameter 96 mm. Productivity - 1.9-2.5 m3 / hour. The optimum head is 55-100 m. Power is 900-1300 watts.

- TS series. These are the most productive devices for the well. They are capable of delivering from 11 to 18 m3 / h. Head - 100-260 m. Three-phase power supply requires consumption of 7.5 kW / h. The impeller blades are made of stainless steel.

Regardless of the type of series selected, you should pay attention to the device labeling. It indicates the nominal head (first digits) and the pump capacity in m3 (second numerical value).

How to choose a pump

- Performance. When buying a pump, it should not be lower than indicated in the technical specifications for the device. Otherwise, the device will quickly drain the source, leading to the risk of idling.

- Well shaft diameter. Important as the pump sleeve may not fit into the barrel. It is desirable that the cross-section of the flask be at least 5-10 mm less than the diameter of the source. Then it is possible to put on a tight rubber ring to protect the casing from the mechanical impact of the steel body.

- Depth of water mirror and well shaft. It is needed in order to calculate the required head for the purchased equipment. It is important to take into account that every 10 m of the horizontal section of the pipeline is equal to 1 m of head. That, in turn, is calculated from the point of the intended immersion to the farthest plumbing fixture in the house. It is necessary to add all the vertical and horizontal sections of the highway in meters.

- Power. Here, each of the masters selects a device according to his capabilities. Someone can afford a more efficient unit. And someone can afford modest models.

Be sure to take into account the productivity of the device per hour. To do this, you need to summarize the amount of water consumed per family over a period of time. Moreover, at all plumbing points of the house.

Installation and connection

- Installing a coarse filter on the inlet pipe (if desired).

- A hose is attached to the outlet using fittings and equipped with a check valve. Approximately 1 m from the pump housing.

- All connections are sealed.

- A safety cable is attached to the eyelet on the device body. Desirable nylon durable, not steel. The latter can rust and break off.

- Parallel to the cable on the ground, lay the required footage of an electric cable and a hose for lifting water.

- So that they do not dangle chaotically in the well, it is advisable to fasten all three elements with ordinary building clamps with a step of 1 m. It is better to cut the tails of the fasteners as much as possible. It is important to ensure that there is no strong tension on the cable, rope or excessive sagging.

- The pump can now be lowered to the set depth. As soon as it reaches the desired mark, the safety cable is fixed to the frame at the head of the well.

It remains to connect the device to the network. If the water is supplied without interruption, then everything was done correctly.

The cost

Prices for submersible pumps for the Belamos well vary depending on the series and technical characteristics of the apparatus. On average in Moscow, you can give the following sums for pumps:

- from 5000 rub. and higher for SP series models;

- from 8000 rub. for TF series devices;

- from 6000 rub. for pumps from the TM line;

- from 13,000 rubles. for centrifugal devices of the TS series.

Prices may vary slightly depending on the region and point of sale.