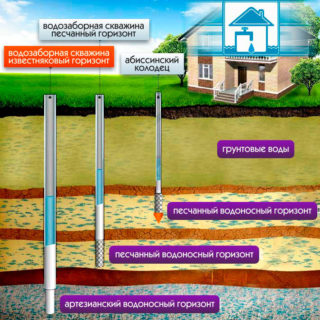

On a suburban area, remotely located from the central water supply, the only way to ensure an uninterrupted supply of clean water suitable for use is to build an autonomous water intake point - a well and a well. The choice of drilling method depends on the depth of the aquifer, as well as the geological features of the area.

The specifics of hand drilling

Drilling wells without visiting the site of special equipment can be carried out in the only case - if it was decided to work manually. The manual method can significantly save the family budget, but you will have to put in a lot of physical effort. It is used in the construction of a source no more than 25 meters deep; do-it-yourself drilling is carried out until the drill reaches the aquifer.

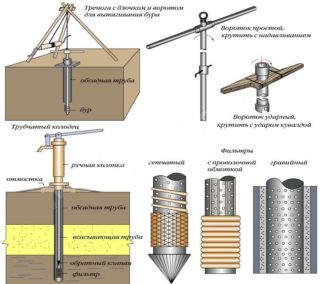

To drill the source yourself, you will need the following working inventory:

- a set of drill heads, for example, bailers, coils, a drill-spoon and a drill-chisel;

- to work at great depths, you will additionally need a drill tower;

- barbells;

- casing;

- electric hoist or winch.

Shaft sinking is carried out using the following technology:

- First, you need to dig a small hole, no more than 40-50 cm deep. A drill will be placed in it.

- One person carefully begins to rotate the drill (it is important that it plunges almost vertically into the soil). As the drill deepens into the ground, one person will rotate it, then two, etc.

- To prevent dirt from clogging up the entire head of the drilling rig, the drill is removed from the soil every 50-70 cm and cleaned.

- If you have to work with hard soil types, the hole should be flooded with plenty of water.

As soon as the hole of the source begins to fill with water from the inside, the drilling work is stopped. The next step is to pump out dirty water with a lot of impurities. For this, a surface or submersible pump is used.

The manual method has many advantages. The main ones are inexpensive production, a homogeneous structure of the trunk along its entire length. Among the shortcomings, they are distinguished - a small debit of the source and a short operational period.

Mechanized well drilling

There are several ways of mechanized well drilling. To choose the most suitable one, you need to learn more about each one.

Shock-rope way of drilling wells

This is the oldest method of all existing, it was invented and actively used for centuries in ancient China. The destruction of the rock occurs due to a sharp mechanical impact - a fall from a height of a heavy bottomhole nozzle. The part is a piece of pipe made of steel with a drill at the end. It is equipped with several holes to clean the object of soil when pulling it out.

Attached to the back of the bucket is a rope or cable that connects it to the top of the derrick. Its height exceeds 2 meters. The method is used to construct a source with a depth of more than 20 meters.

Rotary method

The rotary method of drilling wells is realized with the help of special equipment - a self-propelled drilling rig. Its dimensions and equipment with additional elements will depend on the working conditions.When driving, the drill, equipped with a chisel, rotates the rock and gradually deepens into the soil layers.

- For stony soil, the URB-2A2 unit model is used.

- For tunneling industrial structures, the depth of which can reach 500 meters - URB-3AM.

- In building conditions - MBU-2M.

In the process of wireline drilling of wells, flushing must be carried out, which frees structural parts from layers of worked-out soil.

Auger and core drilling methods for water wells

In the implementation of the auger method, it is necessary to have an auger that works on the principle of an ice auger only of large sizes. For the construction of a well, it is inserted into a previously prepared hole and rotated.

The peculiarities of the method are high productivity, the terms of work are the shortest. This is due to the high rate of rock removal from the well. The screw diameter can be up to 150 cm.

Recommended for use on marshy and sandy soil. The implementation does not involve large financial and physical costs. Among the disadvantages are the lack of the ability to work on stony soil, as well as the limited depth - a maximum of 50 meters.

The core drilling method is most often used for the construction of wells on an industrial scale, as well as for scientific and research work. The use of a special chisel destroys the rock. The hollow tube is additionally equipped with scars. Penetrating into the soil layers, it cuts off from the main layer.

High productivity allows the method to be used not only for the construction of wells, but also in construction, for example, if it is required to make a through hole in a reinforced concrete structure. The bit is driven by a special installation called the ZIF.

The indisputable advantage of the columnar method is that there are small-sized installations that can be installed even on personal plots with a small area.

How to choose suitable methods

The main parameters will help you to choose a suitable method for drilling wells:

- trunk cross-sectional diameter;

- soil type;

- penetration depth.

For sources of a shallow depth of occurrence of an aquifer in soft soil, it is preferable to resort to the manual or auger method of drilling, in solid ground - percussion-rope.

Also, when choosing a drilling method, you need to pay attention to additional selection criteria:

- The financial investments that will be required for the construction of an autonomous water supply network: pocket drilling an artesian well, or enough, for example, a sand one.

- The required volume of water or the debit of the source, which will be enough for a comfortable family living in the house.

- Well water quality (the deeper the depth, the cleaner the water).

- The frequency of use of the source.

If the source is shallow, the climatic and geological conditions of the area, the location of industrial enterprises and agricultural land nearby should be analyzed before drilling.

When constructing an artesian well on a personal plot, you need to draw up an appropriate package of documents and register the source, and this is an additional waste of time and money.

A well-drilled and well-maintained source will serve homeowners for years to come. Before proceeding with the drilling of the source, it is necessary to conduct an examination for the presence of groundwater and select the most suitable place away from cesspools and septic tanks (normative legal acts of SNiP are mandatory for familiarization).